Types of Electrical Wires and Cables – Electrical Technology

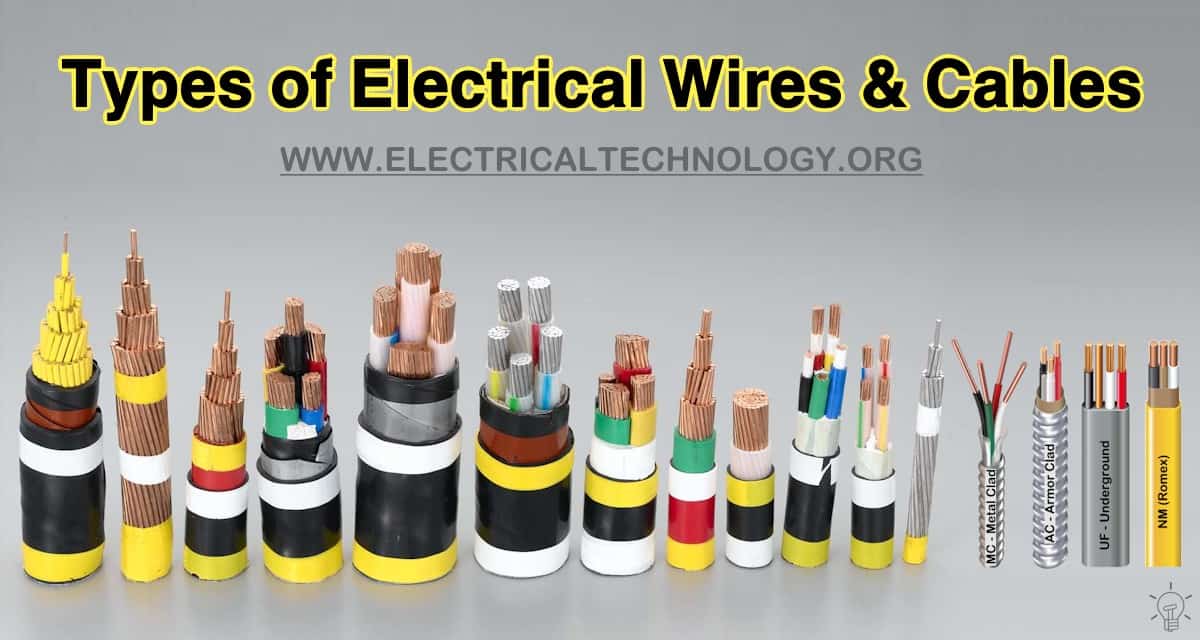

Different Types of Electrical Wires and Cables

Electrical cable and wires are considered as a same thing. In fact they are quite different. A wire is made of a single electrical conductor while a cable is a group or bundle of multiple wires inside a common sheathing. Both of them are used for carrying electrical current.

Nowadays due to the advancement in technology, almost everything is powered by electricity. Be it indoor or outdoor, we need supply of smooth, uninterrupted electricity which is achieved by using suitable type of wires and cables. Not only the electrical sector uses cables and wires for power transmission and distribution to our house and industries, the Telecom sector also relies on various types of cables for uninterrupted data transmission.

Labeling of Cables

The labeling of the cables is very important and it provides a lot of information regarding its insulation types, numbers of wires and the gauge of the wires. Take a look at some of labels written on the wires commonly used in home wiring.

-

14-2G: The cable contains two insulated wires and a ground wire; individual wire is 14-gauge.

-

14-3G: The cable contains three insulated wires and a ground wire; individual wires are 14-gauge.

-

12-2 w/G: The cable contains two insulated wires with a ground wire; individual wires are 12-gauge.

-

12-3 w/G: The cable contains three insulated wires with a ground wire; individual wires are 12-gauge.

-

600 V: This Cable is rated for a maximum of 600 volts; commonly used NM cable for home wiring.

-

TYPE NM-B: NM stands for Non-metallic, it is a non-metallic sheathed cable of type-B; this is the commonly used cable for wiring appliances and devices in home.

The most important label of them is about the insulation or the plastic coating around the conducting wires. Here are some of the common labels written on wires.

-

THHN

-

THWN

-

THW

-

XHHN

The meaning of each letter used in the labels above is given below:

-

T: Thermoplastic insulation, a fire-resistant material

-

H: Heat-resistant; able to withstand temperatures up to 167 F.

-

HH: Highly heat-resistant; able to withstand temperatures up to 194 F.

-

W: “Wet,” or approved for damp and wet locations; this wire is also suitable for dry locations

-

X: Insulation made of a synthetic polymer that is flame-retardant

-

N: Nylon-coated for resistance to oil and gasoline

Related Post: Types of Electrical Drawing and Diagrams

Residential Wiring Cables

The residential wiring from the utility pole to the appliances or devices inside the home is divided into mainly five types.

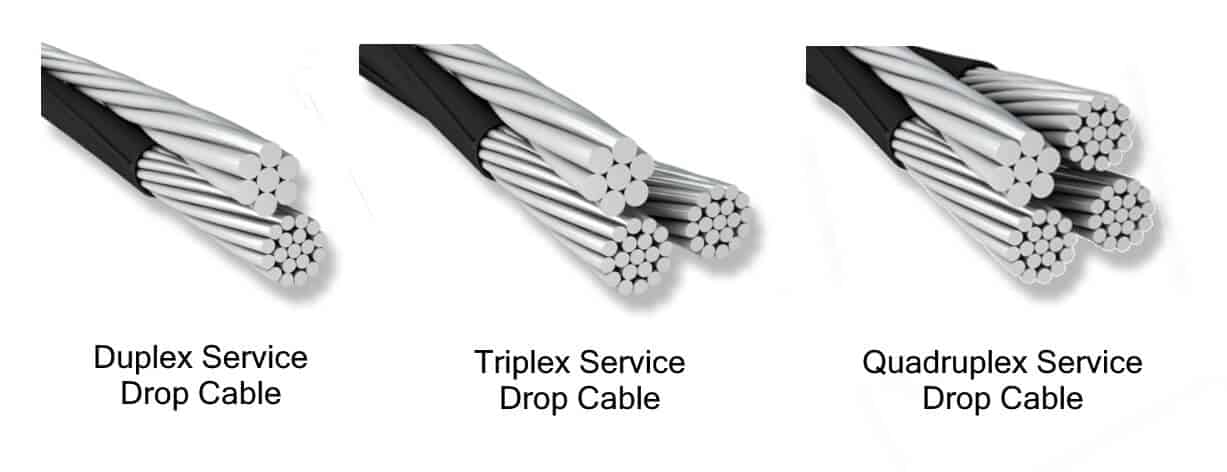

Service Drop Cable:

It is the cable between the utility pole and the consumer’s premises or building. The service drop cable is an overhead electrical line from the pole to the service weatherhead of a house. The service drop cable can be of many types given below:

Duplex Cable: The duplex service drop cable is a two core conductor i.e. it has two conductors; an insulated conductor for phase line and a bare conductor for neutral line. It is used for supplying a single phase power to the building.

Triplex Cable: The Triplex service drop cable is a three core conductor. It has two insulated conductors for phase line and a bare conductor for neutral line.

Quadruplex Cable: The Quadruplex service drop cable is a quad or four core conductors. It has 4 conductors; three of them are insulated conductors for phase lines and a bare conductor for neutral line. It is used for supplying a 3 phase power supply from the utility pole to the building.

The phase conductor is an AAC cable while the neutral conductor is available in AAC/AAAC/ACSR. The insulation used on these cables is XLPE that protects these conductors from moisture, heat etc.

Main Feeder Wires:

The main feeder cables & wires supply the power from the service weatherhead to the building. The cables used for this purpose are 600v THHN, solid or stranded with the rating of 25% more than the maximum required load.

Panel Feed Wires:

The panel feed wires supply power to the main distribution junction box. It is usually black insulted THHN cables with rating of 25% more than maximum load current

Non-Metallic Sheathed Wires:

The non-metallic or NM sheathed wires are used for in-house wiring. It may consist of 2 or more than 2 insulated conductors with an insulated or bare ground conductor. There is another layer of plastic XLPE sheathing for more protection. The latest version NM type-B is currently used by electricians for interior installation. The conductors could be solid or stranded. The stranded conductors are easier to route through conduits.

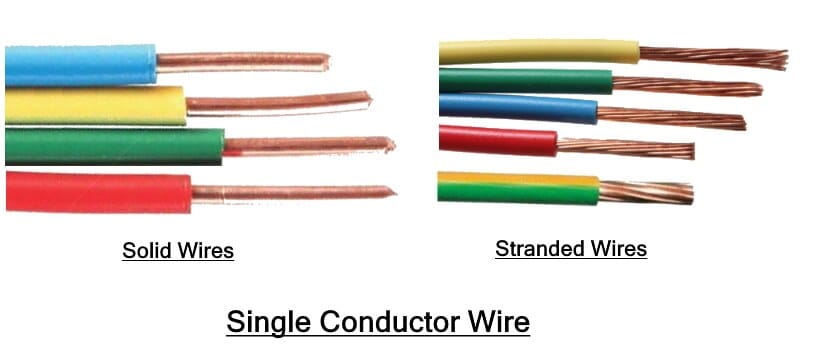

Single Conductor Wire

Single Conductor wire is the most popular choice for electrical layout inside a home. It is available in multiple gauges, color (for phase, neutral and ground identification) and solid or stranded conductors. A single solid wire provides better connections but single stranded wires are easier to route through conduits. Both of them are available in THW and THHN insulation.

Types of Cables and Wires

There are several types of cables and wires depending on their applications and uses.

Communications Cable

The types of cables and wires that are used for communication or signal transmission purposes are called communication cable. There sole purpose is to transmit information. Here are 3 types of communications cables:

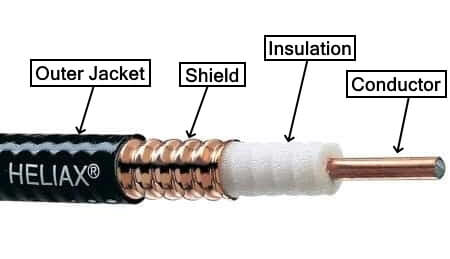

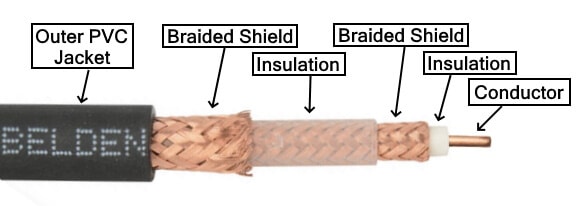

Coaxial Cable

Coax or coaxial cable is type of electrical cable made from four layers, forming coaxial shape (having common axis or center). The central part of coaxial cable is a conductor covered by an insulating plastic layer which is surrounded by a metallic shield. On top that is a fourth layer of plastic insulation.

The coaxial cable is used for transmission of high frequency signal. This is why the metallic shield is used for blocking noise interference. It is commonly used for cable television signal distribution, signal transmission between antennas, transmitter and receiver.

The coaxial cable is further divided into various types and each of them has their own application.

Hard line Coaxial or Heliax Cable

Hardline coaxial or mostly known by its trademark name Heliax cable is a thick coaxial cable with its center solid conductor made from copper and the shield made from copper or silver tubing. It is specifically used for high frequency broadcast transmission. It can carry hundreds of channels and is usually installed between a transmitter on ground and aerial antenna.

Radiating or Leaky Coaxial Cable

Radiating or leaky coaxial cable is another type of coaxial cable where the shield is deliberately designed in such way to radiate RF waves. The shield is made with slots tuned for specific RF wavelength that provide bi directional leakage effect between transmitter and receiver. This type of coaxial cable is used in places where antenna is not feasible such as underground tunnels, elevator shafts etc.

RG-6 Coaxial Cable

RG-6 is the most common type of coaxial cable used for signal transmission in residential and commercial applications. It is made from a solid copper wire with plastic insulation covered by an aluminum foil and a braided shield for protection against interference. It is used for audio and video signal transmission in application such as cable TV, Satellite TV signal and radio etc.

Triaxial or Triax Cable

Triaxial is another type of coaxial cable which includes another layer of insulation and shield over the top of existing shield. The second or outer shield is grounded to protect the inner shield from electromagnetic interference.

Twin-axial or Twinax Cable

Twinax cable is type of coaxial cable similar to RG-6 but with two inner conductors instead of one. The two insulated inner conductors are twisted together surrounded by a braided shield. It is used for high-speed short-range signal communication usually for 10 Gigabit Ethernet Network.

Semi-rigid Coaxial Cable

Semi-rigid coax cable is another type of coax cable where the outer sheath is from solid copper with an inner conductor. The outer shield provides better interference protection. Due to the tube like structure of the shield, it is not very flexible and is not meant to bent after initial forming.

Rigid Line Coaxial Cable

The rigid line coax cable is a modified form of semi-rigid cable made from two concentric tubes (shield) that provides extra protection for high power signal. Such cables are not meant to be bent which is why elbow and interconnects are used for bending. They are used for high power signal transmission between RF components of a transmitter and antenna.

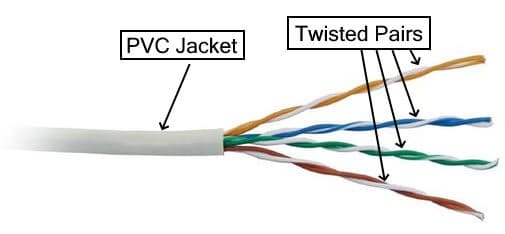

Twisted Pair Cable

This type of communication cable is made from two insulated wires twisted together to form a twisted pair. The purpose of twisting is to reduce the electromagnetic interference or noise. They are used in Ethernet network and telephone communication.

They are further divided into two types based on their noise protection.

Unshielded Twisted Pair (UTP) Cable

The UTP cables do not have any extra shield for protection against noise. They twisted pairs may reduce the noise but it still affects it. Various categories of UTP cables are used in residential and commercial building with various bandwidth e.g. CAT1, CAT2 etc.

Shielded Twisted Pair (STP) Cable

The STP cable has an extra layer of foil that protects the wires from electromagnetic interferences. They are used for high-end applications where the cables may get affected by external environmental interferences.

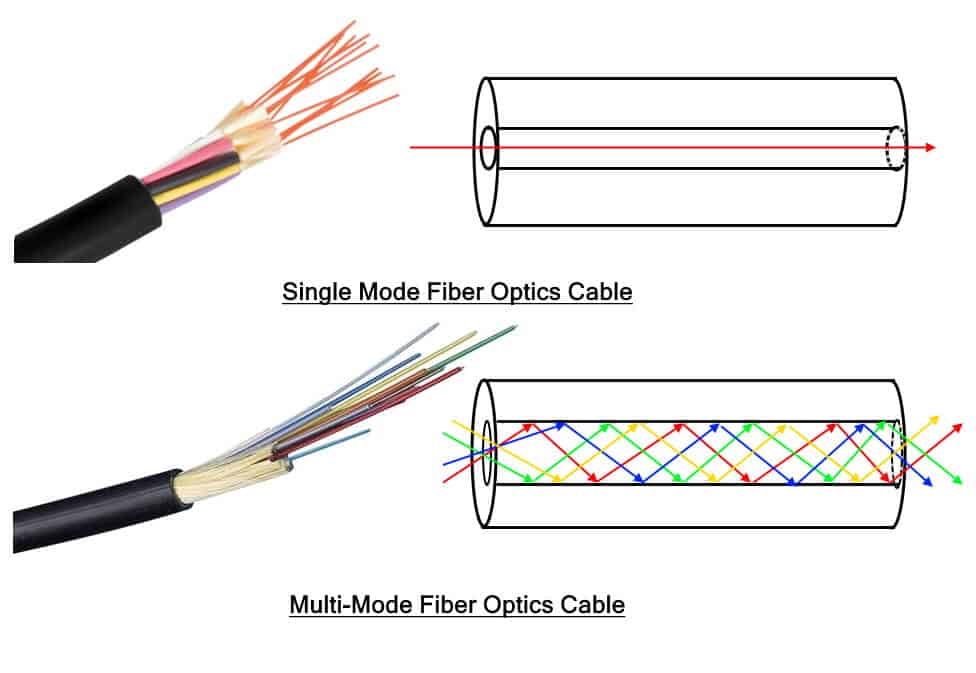

Fiber Optic Cables

Fiber optic or optical fiber cable is a type of communication cable made of flexible, transparent glass fibers known as optical fibers that transmit data in the form of light. The fiber’s thickness is approximately equal to human hair and each individual fiber is covered with plastic insulation. There is another external protection layer that protects the fibers from interference.

The fiber optics cable is classified into two main types;

Single Mode or Mono-mode Fiber Optics Cable:

This cable allows only one mode of light to transmit. It is made of a very thin single strand of fiber that allows only single light wave to propagate. This decreases the number of light reflection which reduces the attenuation in signal. It provide high transmission rate at long distance with very low attenuation but at high cost.

Multi-Mode Fiber Optics Cable:

This type of fiber optic cable is made of relatively thicker fibers that allow more than one light waves so it can transmit relatively more data. But the number of light reflections due to large number of waves at large distance causes attenuation and distort the signal at the receiving end. This is why it is used for relatively short distance transmission such as LAN, security system etc.

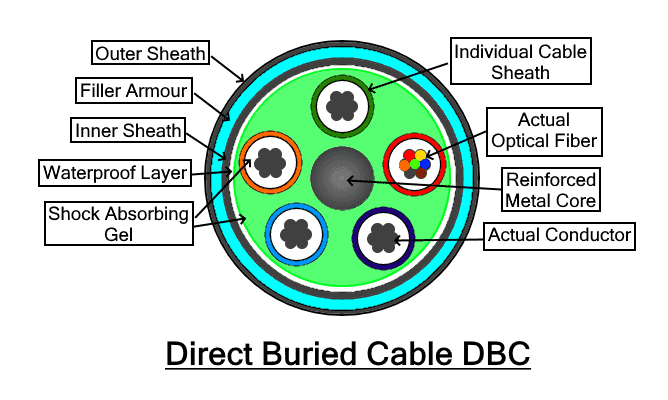

Direct-Buried Cable (DBC)

It is a type of cable used for communication and power transmission. It is specifically designed to be buried directly underground without the need of extra insulation, sheathing or piping. It is made of bundles of fiber optic cables with a thick metal core for stiffness. It has multiple layers of protection such as plastic insulation layer, waterproof layer as well as shock absorbing gel etc. to protect it from heat, moisture and other underground factors.

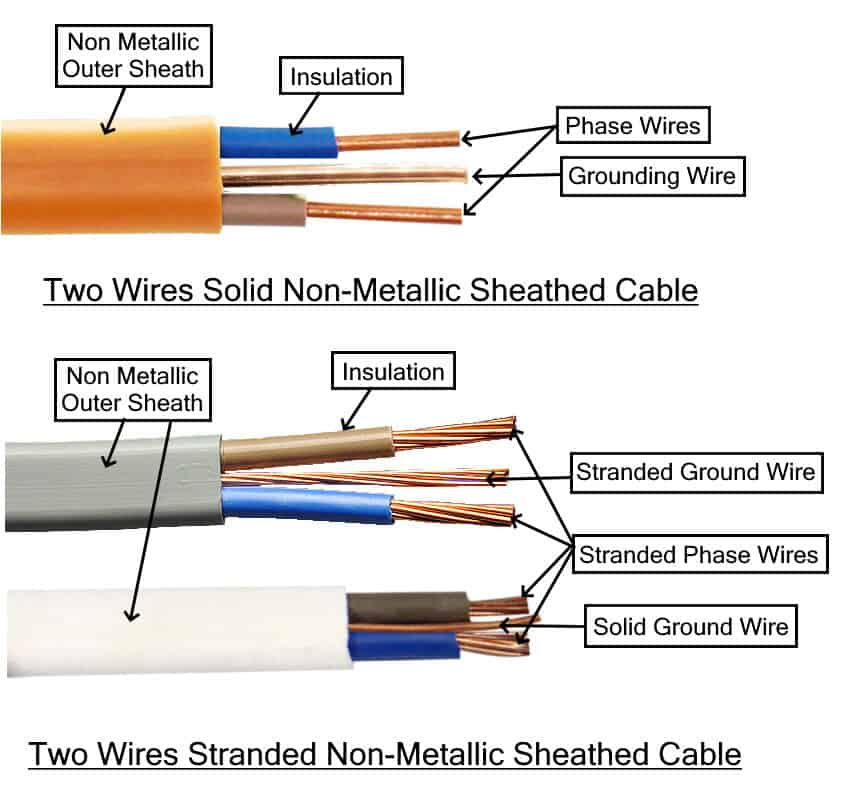

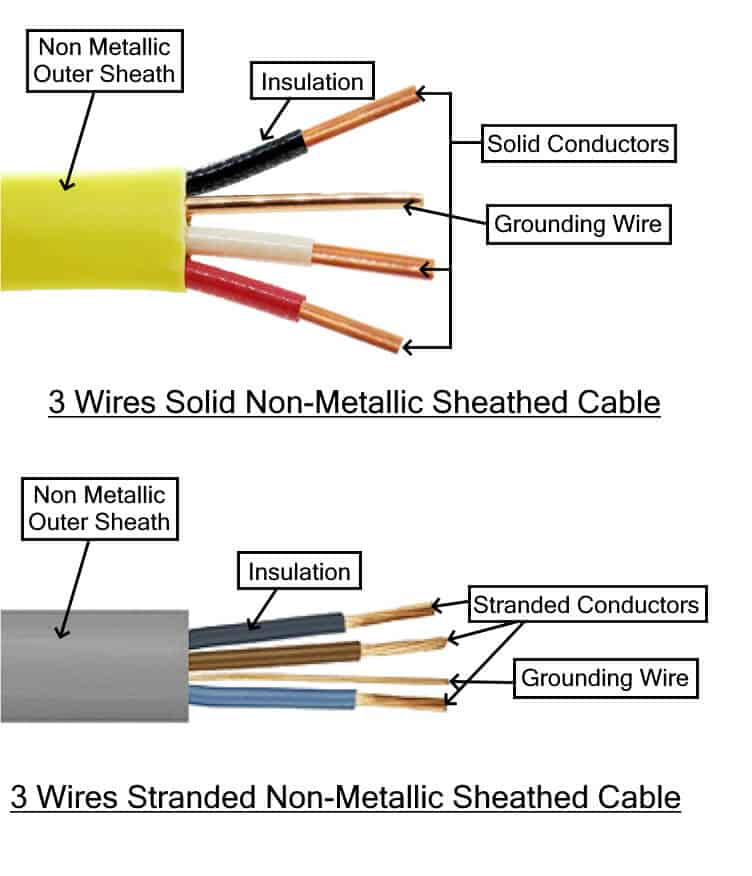

Non-Metallic Sheathed Cable (NM, NM-B)

The non-metallic or NM sheathed cable or known by its trademark name “romex” cable is a type of electrical cable whose outer sheath is made of plastic that protect the inside conductors. It is commonly used for residential electrical wiring.

There are two types of NM sheathed cable based on number of conductors;

Two wires NM sheathed cable: This type of cables has two separately insulated conductors with a bare conductor for ground connection that makes a total of 3 conductors. It comes in various gauges for various ratings and it is labeled as “<gauge> – 2 WG”. It means this cable contains 2 wires plus a grounding wire.

Three wires NM sheathed cable: this type of cable contains 3 insulated wires with a bare grounding wire. It is used for three phase application this is why the individual conductor is marked with different phase color for identification.

The NM wires are available in solid as well as stranded form. The solid conductor provides better connection at terminals but it is difficult to route through pipe or conduits. While the stranded conductors are more flexible and easier to route through conduits.

The NM-B (B for building) is a type of NM cable especially used for indoor building wiring. They are used for wiring inside wall and floors but not to be used in wet places such as external wiring.

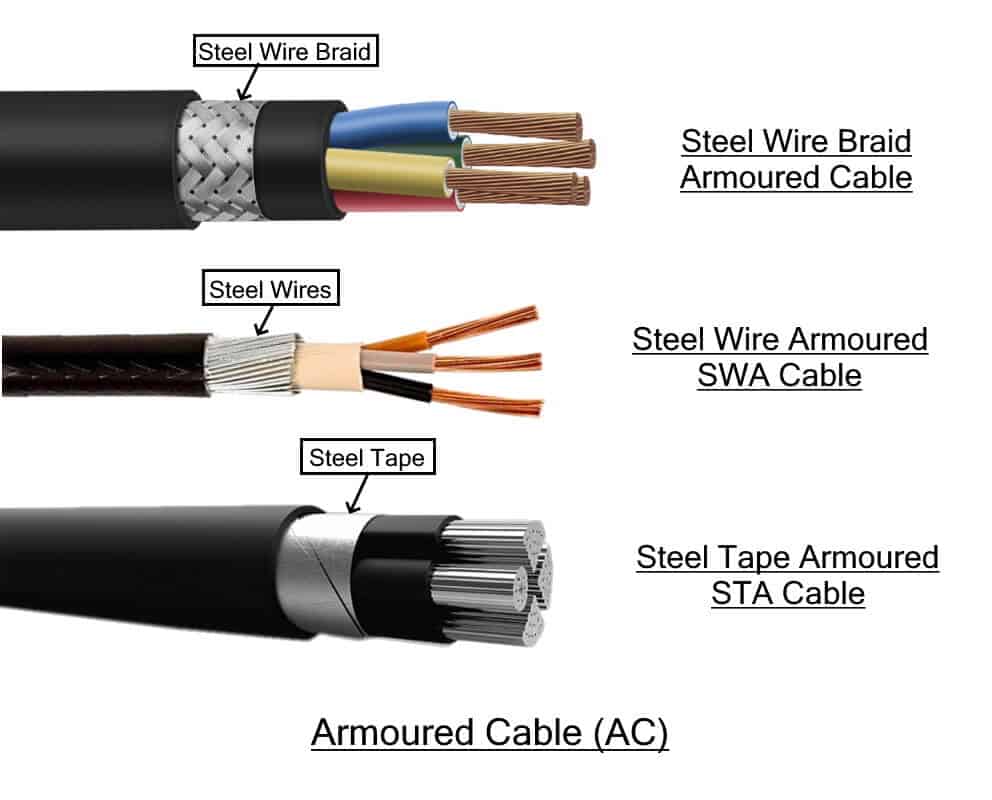

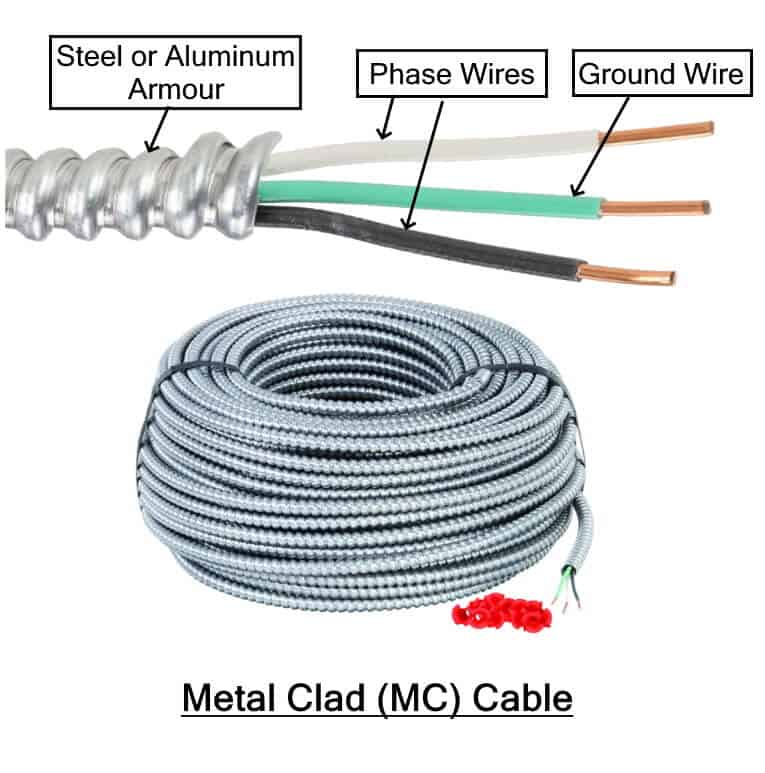

Metallic Sheathed Cable (Armored Cable, AC or BX, MC)

Metallic sheathed cable, as the name suggest is a type of armored electrical cable with a metallic protection over the insulated conductors. The conductors are separately insulated with plastic layer which is surrounded by a metallic sheath for extra protection. The metal sheath can be braided or twisted that surrounds individual or all conductors or it could a solid pipe like structure.

The metallic sheathed cables are mostly known by AC (armored cable) or BX cable and MC (metal clad) cable. BX is the registered trade name for AC cables.

Armored Cable (AC)

Such type of metallic sheathed cables has a protective twisted or braided metallic layer usually made of steel over its conductor. The external sheath is made of plastic. The metallic layer provides extra mechanical strength against any sort of damage and can also be used for grounding connections. Thus they are not used in damp or wet location as well as underground. The armoured layer can be wire braid, steel wire or steel tape. The steel wire armored (SWA) cable is most common type of armored cable used for power transmission.

Metal Clad (MC) Cable

The difference between AC and MC cables is that MC Cable’s metallic sheath cannot be used as grounding wire. It has an extra green colored insulated wire for ground connection. Thus they can be used as direct burial type and in wet locations but if they have their protective PVC outer sheath.

The metallic sheathed cables are expensive and hard to route and needs special tools for cutting or ripping as compared to NM cable which is the best choice for residential wiring. They are used in power supply for large appliance and external use.

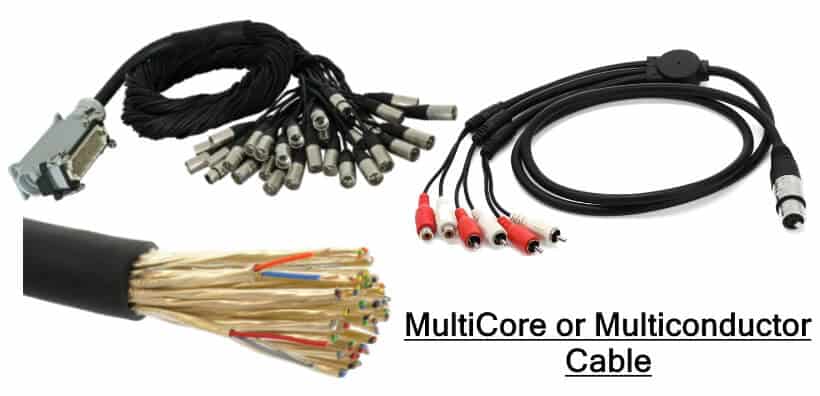

Multi-Conductor or Multicore Cable:

Multi-core or multi-conductor cable has multiple conductors with insulated sheaths that are rolled into one jacketed cable. Its job is to avoid the messy connection by having one single cable instead of 10 or 20 separate wires and save time by connecting them one by one.

The individual conductors have insulation sheath with a common housing made from insulating material. But in some cases, there is an aluminum layer for protection against EMI (electromagnetic interference) or an extra armored layer for more protection. The multiple core cables usually ends in a multi-pin connector.

The cores are the number of useful connections; a simple 3-phase cable cannot be called a multi-core cable but a cable having 2 or more then 2 separate 3-phase conductors is a multicore cable. For example, an audio mixer has multiple input cables from microphones, the cables are joined together to form a multi-core cable which is easier to plug in instead of plugging each cable in its own spot.

They are mostly used in electronics for data transmission in application such as:

-

Transmitting audio signal to audio mixer.

-

Sending audio and video signal in gaming consoles.

-

Sending camera signal to CCU (camera control unit) in TV studios

-

Sending audio and video signal using a single cable from camera.

-

in networking

Paired Cable

Paired cables are type of electrical cable made from a pair of two insulated conductor covered by an insulation sheath. They are mostly used for DC application and also in low frequency AC applications.

Portable or Extension Cord

It is a flexible electrical cable with connectors on both ends to provide a temporary AC power supply. it is usually used as extension of power source for powering portable equipment, machines and devices.

They type of insulation material used for the conductor determines its application or environment of use (such as temperature, moisture, weather, oil etc.). While the rating of cord is determined by the size of the wire conductor.

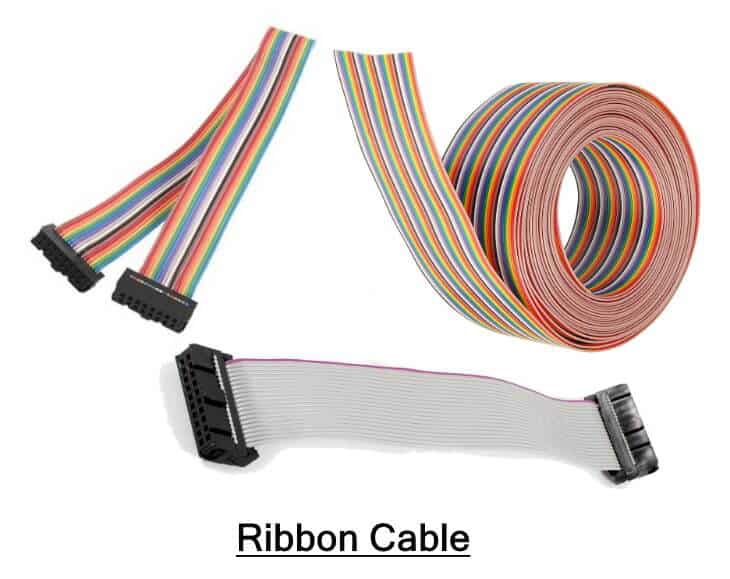

Ribbon Cable

This type of cable is made from multiple small grade insulated wires parallel to each other in a flat shape that resemble a piece of ribbon thus the name ribbon cable. They are flexible and they can handle very low voltages.

They are mostly used in electronic devices and computers to connect different internal peripheral that require data buses like hard drives, CD drives, printers etc. Due to their flat shape, they block the airflow inside computer which affects the cooling system. Nowadays, they are mostly replaced by round cables.

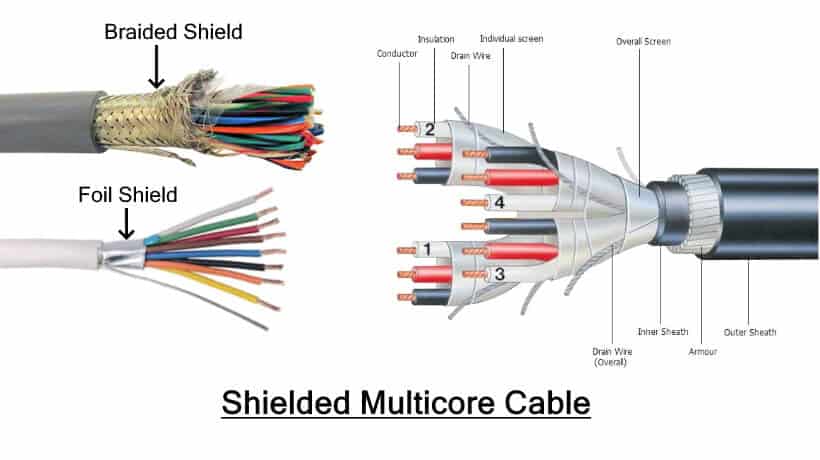

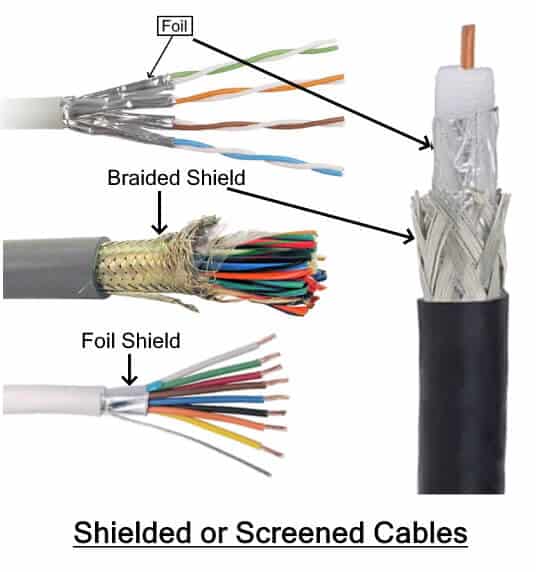

Shielded or Screened Cable

Shielded cable or screened cable is a type of electrical cable whose conductors are protected by an extra metallic layer known as shield. The shield may be made from braided aluminum, copper or any other metal or it could be a foil, a spiral tape or a solid layer made from the said conducting metals.

It provides protection against electrical noise or EMI (electromagnetic interference) generated by any near electrical sources. It is eliminated by grounding the shield at one end. In power cables, the shield layer is grounded to protect the insulation from breaking due to corona discharge as well as avoid electrical shock.

Single Conductor Wire

Single conductor wire or most commonly known as just wire, is made of a single insulated conductor. It is the most popular choice for residential wiring. It is available in multiple colors for phase and earth identification. The single conductor wire has two types;

Single Stranded Wire:

Single stranded wire is made of multiple thin strands of wires that form together one conductor. The stranded design offers flexibility thus they are suitable for applications where wires need to be bent or twisted. Electrician prefer stranded over solid because it is easier to route through pipes in walls due to its flexibility.

Single Solid Wire:

Single solid wire is made of single solid core with plastic insulation. The solid design offer better connection but it is difficult to bend or twist due to its stiffness. Multiple bending might damage and break the conductor inside. They are used in applications where there is no movement or bending required for wires.

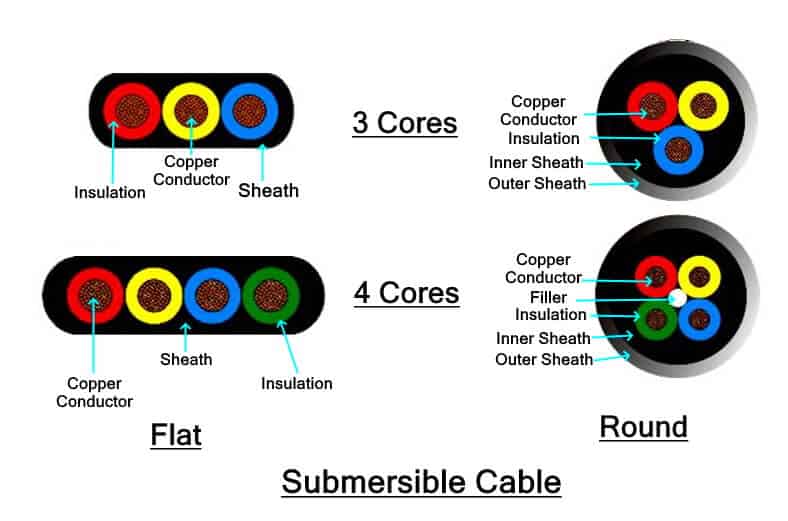

Submersible Cable

As the name suggest, this type of electrical cable is designed to be used in wet locations or submersed in a liquid. The insulation used for such cables is very rugged, abrasion-resilient and extremely durable and reliable to meet the challenges present in the installation environment. They are designed to be used as direct buried cable.

They are available in single as well as multiple conductor design having flat or round structure to meet its applications. The conductors are color coded to identify phase and earth connections as well as the control wires that runs along the power conductors.

They are used in location that is physically restrictive and inaccessible. The most common use of submersible cable is to supply power to submersible motors and pumps underwater, in agriculture industries, underground mining or drilling purposes.

Twin-lead

Twin lead cable is a two conductor flat cable used as a balanced line to carry radio frequency RF signal. The conductors are held apart and uniformly space by a plastic layer between them. The equal spacing is very important because it keeps the signal from distortion. The conductors are mostly stranded to avoid skin effects and they are insulated using the same plastic material.

They are more susceptible to external noise interference and weather conditions that is why these factors are kept in mind during installation. Of course, the coaxial cable has better noise protection but twin lead cable is preferred due to its low power losses.

Ladder Line

Sometimes, due to wet condition such as rain, wind etc. the water drop gets accumulated on top of the plastic between the conductors. This causes interference in the signal. In order to avoid such condition, a window like slots is cut into the plastic layer. The resulting wire resembles a ladder like structure, thus the name ladder Line.

The twin lead is available in 600, 450, 300, and 75 ohm characteristics impedance. The most common type is known by 300 ohm twin lead cable used for television sets. They are mainly used to connect the transmitter or receiver with RF antennas in TV and Radios etc.

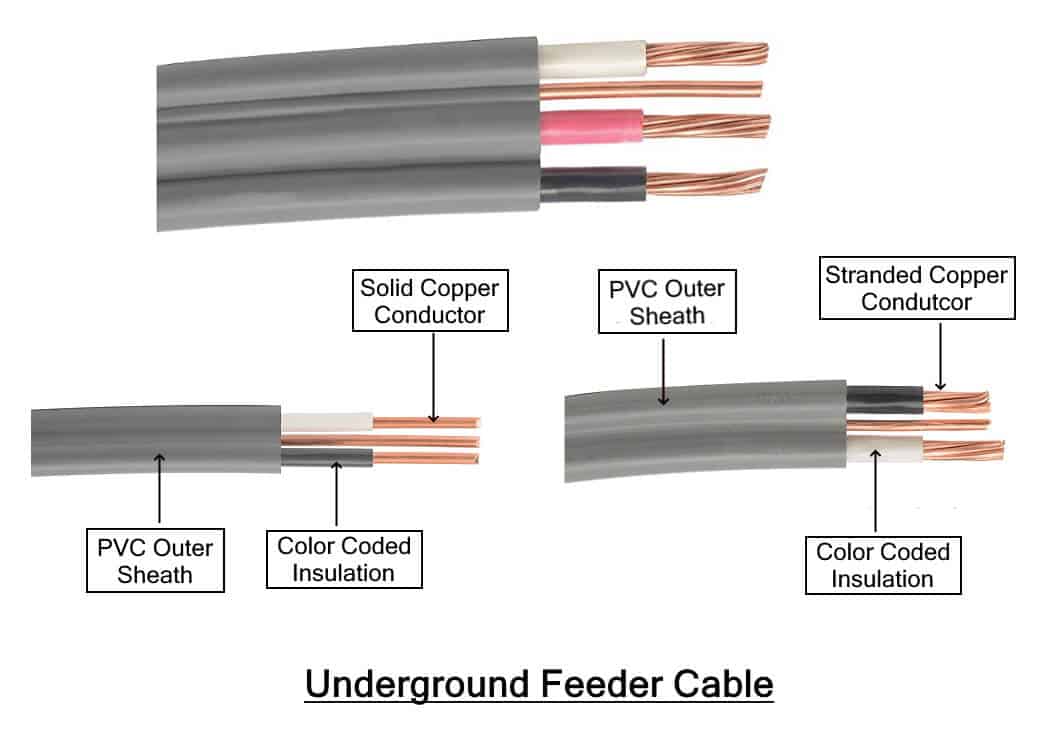

Underground Feeder (UF) Cable:

It is a type of non-metallic sheathed cable designed for use in wet location such as supplying power to lamp post or street light. NM cables have a loose wrap of plastic sheath around it whereas the conductors in UF cables are individually surrounded by a solid layer of thermoplastic that provide flexibility and extra protection. The water-resistant insulation material allow them to be used in damp locations such as supplying power to garden shed, lamp post. They are mostly available in gray color outer sheath. They are the best choice for avoiding poles and exposed wire by simply running them underground.

Flexible Cables

Flexible cables are a type of electrical cables that can withstand continues bending in moving applications. The flexibility is achieved by using stranded conductors. They are used in automation industries where the machines are continuously moving such as pick and place machines and CNC based machines such engraving, milling machines etc.

The flexible cables are of two types;

Stranding in Layer

This type of cable is made from multiple layers of strands of conductor. The cores of this cables is designed to be firm and the surrounding layers are made long. Because the outer layer stretches during bending while the center core compresses. This type of cable is easier to manufacture and is cheaper. The material used for such cable is flexible but too much bending might deform the cable.

Stranding in Bundles

This type of cable is achieved by braiding the conductor around each other so that the conductor stretches uniformly when the cable bends. This type of cable is more durable because of its tension proof core but a little stiffer than the stranded cable.

Overhead Power Line:

Overhead power lines are conductors suspended from electrical towers or poles to transmit power over long distance. The conductors used are completely bare and made from aluminum. The electrical and mechanical properties of the conductor depend on its construction. Here are some of the cables used for power transmission.

All Aluminum Conductor (AAC)

AAC transmission cable, also known as aluminum stranded conductor is made from multiple strands of hard drawn 1350 aluminum alloy which is 99 % pure with a little bit of silicon, iron etc. it has very high conductivity and resistive to corrosion but very poor strength to weight ratio. That is why it is preferred short distances in the stations not for rural power transmission over long distance.

All Aluminum Alloy Conductor (AAAC)

In order to increase the mechanical strength of the AAC cable, a special aluminum alloy is used made with magnesium and Silicium. It increases the strength to weight ratio while maintaining the corrosion resistivity. However, the conductivity falls a bit

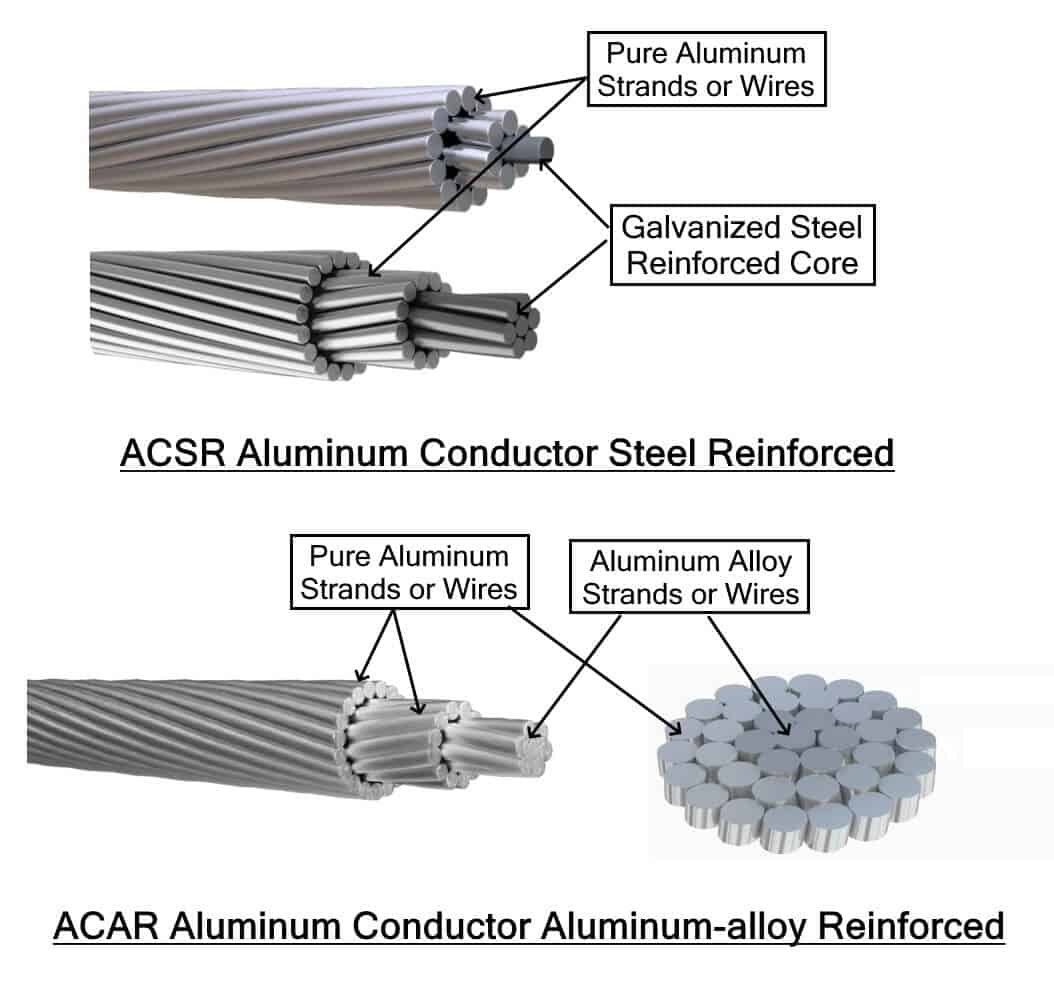

Aluminum Conductor Steel-Reinforced (ACSR) Cable

ACSR is also a stranded aluminum cable whose inner strands are made from galvanized steel surrounded by strands of pure aluminum conductors. The steel core increases the tensile strength of cable while the aluminum provides good conductivity and low weight. They are used in long distance transmission line because we can alter the strength of its steel core to meet the requirement.

Aluminum Conductor Aluminum-alloy Reinforced (ACAR)

It is made of pure aluminum conductors surrounding an aluminum core. The structure of ACAR resembles ACSR but instead of its core made from galvanized steel, it is made of aluminum alloy which increase the overall conductivity (ampacity) while maintaining the tensile strength if ACSR.

Bundled Conductors:

Due to high voltage transmission of above 132KV over long distances, a phenomenon occurs in the conductors known as corona discharge. High voltage ionizes the air around it which causes power loss as well as interference in the communication lines nearby. To reduce this effect 2 or more than 2 conductors are used per phase also known as bundled conductor. These conductors are made from same materials and are equally separated by a spacer.

Related Posts:

URL Copied

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)