Pneumatic Actuators vs Electric Actuators: Which is Better?

Pneumatic linear actuators and electric linear actuators are often compared for linear motion requirements that do not require the high forces of hydraulic linear actuators. Here are 15 factors that should be considered.

First, what’s an actuator?

According to Wikipedia, an “actuator” is a component of a machine that is responsible for moving and controlling a mechanism or system. A “linear actuator” is an actuator that can either push with a thrust force or carry a load linearly to specific positions. While the structures are similar, the differences in actuators start with their source of power, which can be hydraulic (fluid), pneumatic (air), or electric (AC/DC).

The right type of linear actuator to use is determined by how well it can meet the application requirements, such as load, speed, accuracy…etc.

For example, pneumatic actuators can provide a higher speed, but electric linear actuators provide the most precise control since air and fluid pressure are more difficult to control than electricity.

For the average load that does not require extremely high forces from hydraulic actuators, the solution is either a pneumatic actuator or an electric actuator.

In this post, we will compare the pros and cons of pneumatic actuators vs electric actuators to help you make the right decision for your next project.

Here are 15 factors to consider when deciding between pneumatic actuators or electric actuators.

Pneumatic Actuators

Electric Actuators

Design

Simple

Complex

Force

Depends on air pressure

Depends on screw pitch/lead

Speed

High

Low

Accuracy

Low

High

Repeatability

Low

High

Motion Control Capability

Low

High

Efficiency

Low

High

Cost

Lower initial cost

Lower total cost of ownership

Data Collection

Still developing

Highly developed

Environment

Harsh, hazardous

Refer to IP rating

Temperature

Higher ambient temperature

Lower ambient temperature

Noise

High

Low

Maintenance

High

Minimal

Life

Estimated

Calculated

Ideal Application

End-to-end postioning

Multi-point positioning

Please read on for more information.

Design

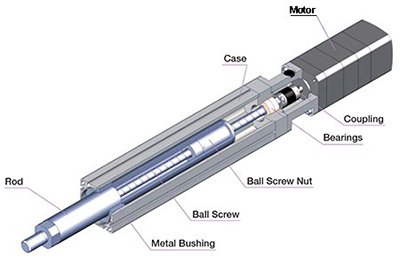

Pneumatic actuators are simpler in their design while electric actuators use more complex components, such as the ball screw and the electric motor.

The simple design of a pneumatic actuator is also more compact than an electric actuator, but when you consider all the other components that are necessary to maintain that air pressure, it can actually take up more space. More on this later.

Here we compare a typical pneumatic actuator with an electric cylinder with a ball screw.

Pneumatic Actuator

Electric Actuator with a Ball Screw

Source:

https://www.globalspec.com/learnmore/flow_transfer_control/valve_actuators_positioners/pneumatic_valve_actuators

Source:

https://www.orientalmotor.com/linear-actuators/linear-actuators-eac-az-series-absolute-encoder.html

A pneumatic actuator is also easier and quicker to install due to its simple design. However, its motion profile is more difficult to change after sizing. An electric actuator also requires sizing and more complicated programming to set up its parameters upfront, but it can change its motion profile fairly easily as long as the required torque, speed, or load inertia doesn’t increase.

TIP

: How do They Work?

Pneumatic actuators are composed of a simple piston inside a hollow cylinder. The position of a pneumatic actuator is controlled by regulating the air into the valves, which moves the piston within the cylinder housing against the spring force. When there’s no air pressure, the spring force moves the piston back to its original home position.

Electric actuators convert the rotational force of an electric motor into a linear force with a specific mechanism, such as a ball screw. By rotating the actuator’s screw with the motor, the ball screw nut will move along the screw forward or backward. The position of an electric actuator is controlled by regulating voltage and current.

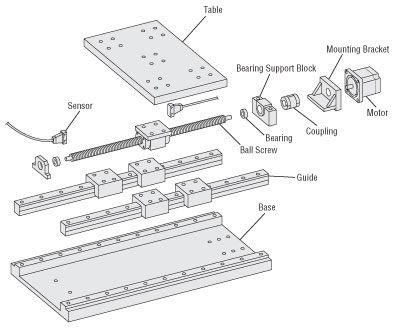

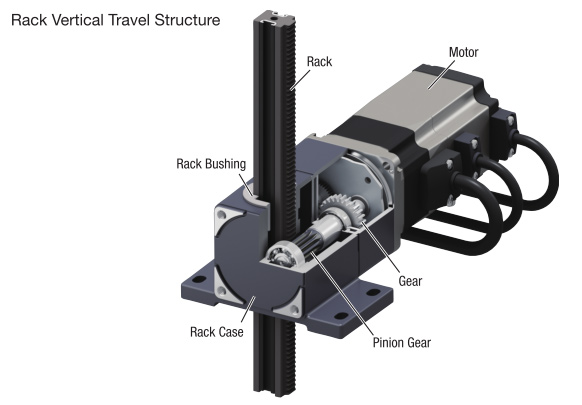

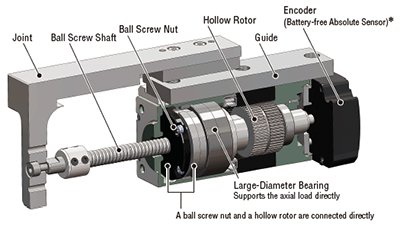

While the basic design of pneumatic actuators is similar, electric actuators can be driven with several different mechanisms, which include a ball screw, lead screw, rack and pinion, belt and pulley…etc. The mechanism alters the final specifications, such as load, speed, and accuracy, in order to suit certain application requirements better.

FYI here are some examples of different types of electric actuators.

Electric Slide

Rack and Pinion

Hollow Rotor

There are also different designs for pneumatic actuators as they can differ in the number of pistons in the cylinder. More pistons equal more force, but it also requires more compressed air.

Force & Speed

Traditionally, pneumatic actuators provide higher speeds and lower forces when compared to electric actuators. However, a few factors, such as screw pitch/lead from an electric actuator, or the number of pistons in the pneumatic actuator, can affect the comparison.

For a pneumatic actuator, the force is calculated by multiplying the piston area (force factor) by the air pressure in the cylinder. For an electric actuator, the linear force is converted from the motor’s torque.

It’s difficult to maintain a set speed or force consistently when you’re dealing with compressed air. Since voltage and current are easier to control, electric actuators can maintain force and speed much better even without closed-loop feedback. Ball screws or rack and pinion mechanisms on electric actuators also act as a gear reduction ratio, so forces can be increased with sacrifice to speed.

There are many options for electric actuators, so make sure you’re comparing apples to apples. Even switching out a ball screw with another ball screw with a higher pitch/lead will alter the final specifications as you can see in the chart below.

The following chart depicts an example of force vs speed for linear actuators.

Source: https://www.medicaldesignbriefs.com/component/content/article/mdb/features/articles/26236

Pneumatic actuators typically operate from 80 to 100 PSI, and electric actuators convert the motor torque and RPM to a linear force and linear speed. To increase the force or speed of a pneumatic actuator, more pistons and/or air PSI is needed. To increase force or speed or acceleration for an electric actuator, more torque from a bigger or longer motor is needed.

Accuracy & Repeatability

Electric actuators dominate accuracy and repeatability, which makes them ideal for multi-point positioning applications.

Source: https://www.linearmotiontips.com/does-my-system-need-high-accuracy-or-repeatability-or-both/

Since voltage and current are easier to control than air pressure, electric actuators can accurately control their position and repeat that position with the same motion profile. Pneumatic actuators are typically chosen for simple end-to-end positioning applications since they simply cannot achieve the same accuracy and repeatability as electric actuators.

Electric actuators use either servo motors or stepper motors, which already offer high stop accuracy and torque control capability. The holding torque from the motors also prevents position drifting.

One thing I noticed is that pneumatic actuators are gradually becoming more advanced as they adopt similar controls as electric actuators, but they would still require additional sensors and programming to achieve close to the “off-the-shelf” accuracy and repeatability of electric actuators while taking up I/O on a PLC.

Motion Control Capability

With more precise control of torque, speed, and acceleration/deceleration patterns, electric actuators can do more with motion profiles than pneumatic actuators.

For example, the following motion profile depicts what an electric actuator or motor can do.

Source: https://www.digikey.com/en/blog/motion-control-profiles-good-better-and-best

It will be difficult to repeat this exact motion profile with a pneumatic actuator.

Electric actuators are the most capable of repeating specific motion profiles due to their precision and accuracy. Pneumatic actuators are limited in their motion profile generation, and motion profiles are more difficult to change once implemented. For this reason, pneumatic actuators are chosen for single-axis, end-to-end positioning applications. Due to high repeatability, electric actuators are often chosen for multi-point positioning applications and where multiple axes need to be synchronized.

For electric actuators, hundreds of target positions can be saved and stored for multi-point operation. Vibration and shock loads can be minimized with modified motion profiles, such as S-curves, whereas pneumatic actuators need a hard stop and spring.

Absolute position control has also been advancing for electric actuators for quite some time. For example, in addition to servo motors with absolute encoders, closed-loop stepper motors with built-in multi-turn mechanical absolute encoders can also help minimize footprint by eliminating the external home and limit sensors. The difference is that the mechanical absolute encoder does not need a backup battery like an absolute encoder. Pneumatic actuators have started to offer absolute feedback, but they’re not as common.

Efficiency & Cost

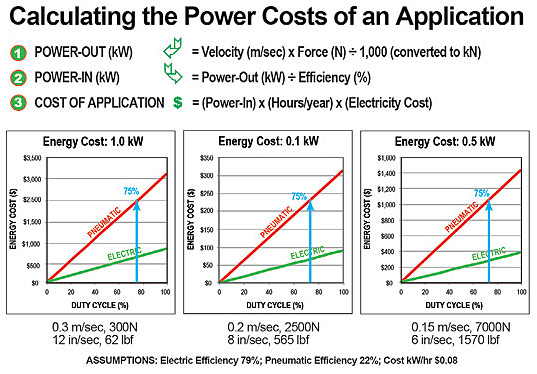

Another major benefit of electric actuators is efficiency. Pneumatic actuators operate at about 10~25% efficiency, which is even lower than hydraulic linear actuators at ~40%. Electric actuators operate at around 80% efficiency.

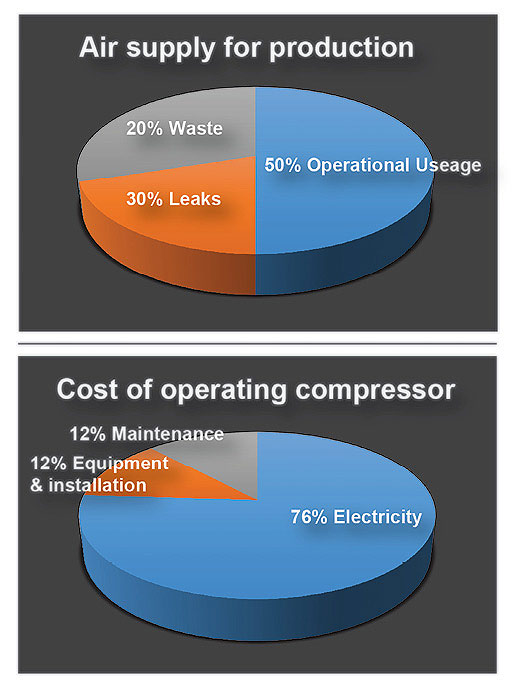

Efficiency affects power costs in the long run. Here we compare the energy costs of a pneumatic actuator vs an electric actuator in the same application.

Source: https://www.linearmotiontips.com/electric-actuators-vs-pneumatic-cylinders-total-cost-of-ownership/

“Compressed air is one of the most expensive sources of energy in a plant. The overall efficiency of a typical compressed air system can be as low as 10 to 15%.”— U.S. Department of Energy: Energy Tips-Compressed Air, August 2004.

If the initial cost is important to you, pneumatic actuators are the way to go. In comparison, electric actuators have higher initial costs but lower operating and maintenance costs.

However, when you factor in the long-term total cost of ownership, electric actuators actually come out on top. This is because both air and fluid power take more work to maintain and are less efficient than electric power.

Source: https://www.techbriefs.com/component/content/article/tb/supplements/mct/features/articles/35859

Short-term costs consist of the system cost, but the total cost of ownership includes replacement costs, air line installation, and maintenance. Remember that air compressors also need electricity to operate.

TIP

: What is Total Cost of Ownership?

Total cost of ownership = initial purchase cost + (# of years of service x annual operating costs)

FYI annual operating costs = electricity + replacement costs + maintenance costs + scrap costs + lost production costs due to maintenance

According to the Department of Energy, “24 percent of the annual cost of compressed air is due to maintenance, equipment and installation while 76 percent is due directly to the cost of electricity for the compressor.”

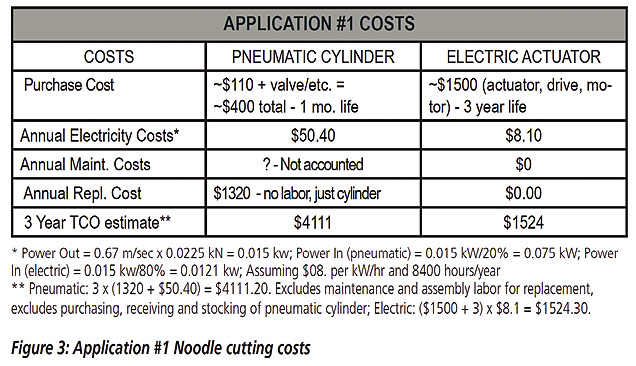

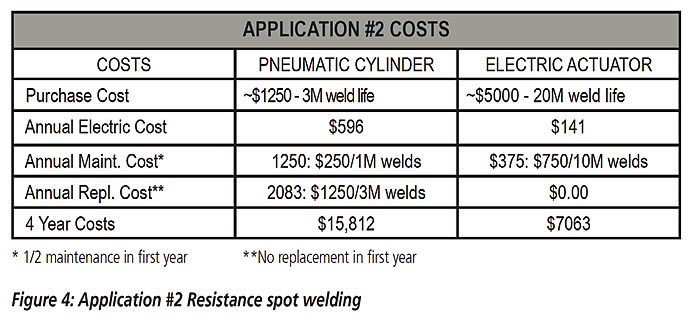

Here are two application examples I gathered from Linear Motion Tips. Application #1 is for a noodle cutting application, and application #2 is for resistance spot welding.

Source: https://www.linearmotiontips.com/electric-actuators-vs-pneumatic-cylinders-total-cost-of-ownership/

Total cost of ownership comparisons between pneumatic and electric linear actuators include many variables and assumptions. Sometimes, it comes down to the design of tube fittings, how well the systems can be maintained, and how you use it. For applications that do not require precision or continuous service life, pneumatic actuators can save some money.

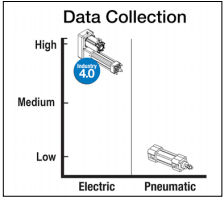

Data Collection

Data collection can lead to better efficiency or predictive maintenance. Electric actuators are the winners in this category, too.

Source: https://www.tolomatic.com/info-center/resource-details/a-technical-comparison-performance-of-pneumatic-cylinders-and-electric-rod-actuators

The control side of electric motors and actuators has been advancing for a long time, so they use more sophisticated controls. Data collection is easier to implement since many of these functions are already included. More industrial network communication protocols, such as EtherNetIP, Profinet, and EtherCAT, are readily available to connect to a variety of PLCs, HMIs, and IPCs. Although pneumatic actuators are also advancing, it may be challenging to catch up to a point where the data can be used to control a process in real-time.

Environment, Temperature, and Noise

Since electric actuator systems can include more sensitive components, such as motors, encoders and sensors, pneumatic actuators are more well-suited for hazardous environments. However, pay attention to the ingress protection (IP) rating and/or specifications in order to understand what environment it can handle exactly.

Pneumatic actuators can sometimes handle a wider ambient temperature (about -20~350°F) than electric actuators (40~150°F), but when pneumatic actuators work in high ambient temperatures, the air seals can fail, and operation could be sluggish. High heat can also affect the bearing grease life of an electric motor and affect metal expansion properties, which can increase friction and wear in an electric actuator.

Pneumatic actuators are also noisier than electric actuators due to compressed air. However, this has also improved over the years.

Maintenance

If you don’t like maintenance, electric actuators are the way to go.

The maintenance needs of a pneumatic actuator are very high compared to an electric actuator. There needs to be a constant supply of compressed air from a reservoir tank, which is not easy to maintain. In addition to the actuator, there are more components to maintain, such as the compressor, valves, fittings, muffler, lubricator, filter regulator lubricator, solenoid, and air tubing.

An electric actuator requires minimal maintenance since there are fewer components that could wear out due to the minimized friction from the bearings and linear guides. An occasional greasing may be necessary. If you take out the actuator from the equation, an electric motor can be considered a non-maintenance item as the cost of repairing a motor often exceeds the cost of buying a new motor.

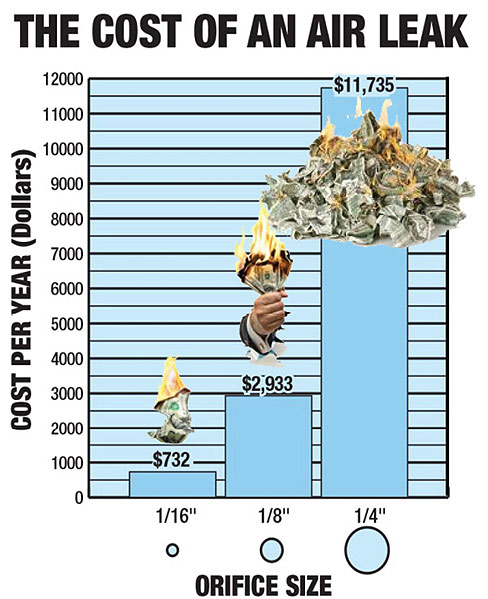

Preventing air leaks is important when using pneumatic actuators. As seals wear, the force produced by the pneumatic actuator will vary, thus making both accuracy and repeatability even worse. Pneumatic actuators depend on tight rod and piston seals to prevent air leakage due to wear and tear. Sometimes, it could take a long time to adjust or regulate the airflow.

Here’s more data for air leaks for a pneumatic actuator.

Source: https://www.linearmotiontips.com/electric-actuators-vs-pneumatic-cylinders-total-cost-of-ownership/

Service Life

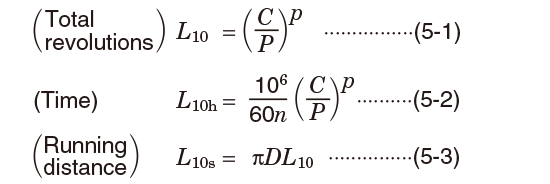

Both pneumatic actuators and electric actuators offer medium L10 service life based on bearing life.

However, the life of an electric motor can be calculated, while the life of a pneumatic actuator can only be estimated. Predicting when the air seals would fail is very difficult, so periodic maintenance is a must for pneumatic actuators.

TIP: What’s L10 Life?

L10 life is the number of revolutions or hours that 90% of a group of apparently identical bearings will complete or exceed before fatigue is expected to occur. It’s a common method to estimate the life of an electric motor.

Since bearing life is based on gearing grease life, and bearing grease life is lowered by high temperatures, keeping the ambient temperature as low as possible will help increase service life.

Here’s a calculation example from Koyo Bearings.

The key to extending life for pneumatic actuators is to keep the rod and piston seals secure. Wear and tear of the seals is unavoidable. If air leakage increases, efficiency, force, speed, and responsiveness will suffer. The key to extending life for electric actuators is to keep operating temperature low. Always operate within specifications for both.

Ideal Application

The design differences between pneumatic actuators and electric actuators lead to differences in their characteristics. As a result, the coarse characteristics of pneumatic actuators make them ideal for basic, end-to-end positioning applications while the precision of electric actuators makes them ideal for multi-point positioning applications with advanced motion profiles or multi-axis synchronization.

Pneumatic actuators can work in more hazardous environments than electric actuators. However, high temperatures can decrease service life for both types of actuators.

If advanced operation, such as closed-loop feedback or data collection, is necessary, electric actuators present an integrated option that should be easier to use for years to come.

Summary

In the simplest terms, the choice between pneumatic actuators and electric actuators comes down to simplicity, precision, efficiency, and maintenance.

Pneumatic actuators are smaller, are easy to set up, and can easily meet simple, short-stroke, end-to-end positioning requirements. Electric actuators, on the other hand, can meet stricter requirements with their superior precision and repeatability, and they’re well-suited for long stroke, multi-point positioning applications with advanced motion profiles.

Although initial costs favor pneumatic actuators, it’s important to consider the total cost of ownership, which includes the initial purchase cost, operating costs, and maintenance costs. Remember that the air compressors used for pneumatic actuators also use electricity. Operating and maintenance costs for electric actuators can be lower in the long run.

The case for switching pneumatic actuators to electric actuators makes sense for applications requiring position, speed, acceleration, and force with better accuracy and repeatability. They are also better at data collection and synchronized multi-axis applications.

With efficiency and cost reduction trending lately, the demand for linear actuators with high power efficiency and low weight will drive the demand for linear actuators.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)