PMSM Motor for Electric Vehicles:

Please share and spread the word:

![]()

![]()

![]()

PMSM motor Permanent Magnet Synchronous Motor is a type of Permanent Magnet Motor widely used in Electric vehicles. PMSM motors are up to 15 percent more efficient than Induction motors and are the most power-dense type of traction motors.

The latest PMSM motors are being used in today’s Electric vehicles (EV) and Hybrid Electric Vehicles (HEV).

Mục Lục

Main Components of Electric Vehicles:

Parts of Electric Vehicle

Parts of Electric Vehicle

- Traction Battery Pack

- DC-DC Converter

- PMSM Motor

- Power Inverter

- Charge Port

- On-board Charger

- Power Electronics Controller

- Thermal System (Cooling)

- Transmission unit

Working Principle of Electric Vehicles:

The power for the electric motor PMSM is converted from the DC Battery to AC via DC to DC converter and Inverter. As the accelerator is pressed, a signal is sent to the controller. The Controller adjusts the speed of the vehicle by changing the frequency of the AC power from the inverter to the motor.

Electric Vehicle Working

Electric Vehicle Working

With the controller set, the inverter then sends a certain amount of electrical energy to the motor (according to the depth of pressure on the pedal) Electric motor converts electrical energy into mechanical energy. Rotation of the motor rotor rotates the transmission so the wheels turn and then the car moves.

If the brakes are pressed, or the electric car is decelerating, the motor becomes an alternator and produces power, which is sent back to the battery.

Now, let’s discuss the PMSM motor used in Electric Vehicles in detail.

What are the types of Permanent Magnet-PM Motors?

The two most common types of Brushless PM motors are classified as:

- PMSM or Brushless AC

Synchronous, with a uniformly rotating stator field as an induction motor. This type is also referred to as Brushless AC-BLAC Motors. - PMDC or Brushless DC

Switched or trapezoidal, with stator fields that are switched in discrete steps. This type is also referred to as Brushless DC-BLDC Motors.

Construction of PMSM Motor for Electric vehicles:

- The Stator of PMSM Motor:

- As in common AC induction motors, electrical power is supplied through the stator windings.

- PMSM stator windings are typically distributed over multiple slots in order to approximate a sinusoidal distribution so that the resulting back-EMF waveforms generated are Sinusoidal shaped.

2. The Rotor of PMSM Motor:

There are two basic constructions of the PMSM motor – a structure that is based on the method of arrangement of the magnets on the rotor.

If the magnets are mounted on the surface of the rotor of the motor, the PMSM motor is called a Surface-mounted Permanent Magnet machine. If the magnets are mounted within the rotor, then the PMSM motor is called internally fitted with permanent magnets known as Interior Permanent Magnet (IPM) synchronous machine.

PMSM Motors used in Electric Vehicles:

Interior Permanent Magnet (IPM) synchronous motors possess special features for adjustable-speed operation. Motors with interior permanent magnet (IPM) rotors can provide exceptionally high efficiency.

Construction of IPM SM Motor

Construction of IPM SM Motor

- Permanent magnets are embedded within the rotor laminations internally fitted with a permanent magnet motor.

- PMSMs are the only variety that contains rare earth Permanent Magnets. PMSM use neodymium-iron-boron (“NdFeB”) permanent magnets, which contain the rare earth elements neodymium, praseodymium, dysprosium and terbium.

- On average, a PMSM for an EV contains approximately 1.2 kg of NdFeB magnets per 100 kW of peak motor power yielded.

- Since the magnets are embedded in a rotor, the centrifugal force during motor rotation does not make the magnets fly out and the mechanical stability is high.

- These motors can use both the torque due to magnet magnetization and the reluctance torque due to rotor magnetization.

3. PMSM Motor Drive of Electric Vehicles:

- All PMSM motors require a matched PM-Drive.

- PMSM drives substitute the more traditional trapezoidal waveform’s flat tops with a sinusoidal waveform that matches PMSM back EMF more

closely, so torque output is smoother.

Working of PMSM Motor for Electric Vehicles:

A “PMSM”, which stands for “permanent magnet synchronous motor”, relies on magnets to turn the rotor, which spins at the same speed as the PMSM’s internal rotating magnetic field.

PMSM motor drives the three phases are always excited during the electrical period, making it necessary to use at least one rotor position sensor.

Working on PMSM Motor for EV

Working on PMSM Motor for EV

By continuously detecting the rotor angular position and rotational speed, the excitation can be properly switched among the PMSM motor phases in exact synchronism with the rotor motion using a Power electronic control circuit known as PMSM Drive.

This concept, commonly known as self-synchronization, uses direct feedback of the rotor angular position to ensure that the PMSM machine never loses synchronization. Generally, Hall sensors are used to get information about the angular position of the rotor, detecting the magnetic field direction generated by the rotor.

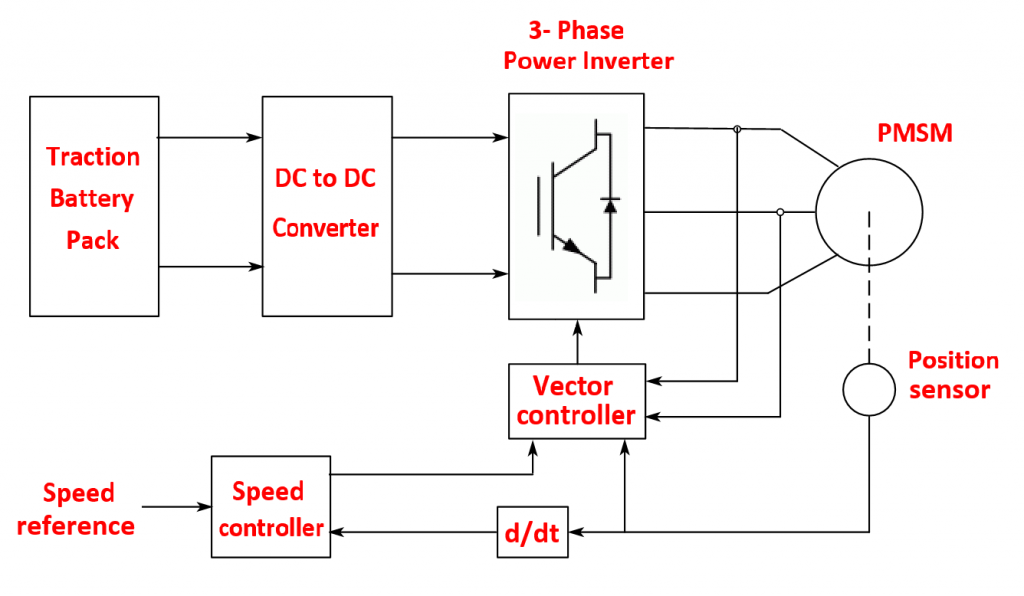

Vector Controlled PMSM-Drive Operation in an Electric Vehicle:

The PMSM Drive is a classical vector control drive for Permanent Magnet Synchronous Motors. This drive features a closed-loop speed control based on the vector control method. Closed-loop configuration provided with speed feedback. Feedback allows the drive to track the exact rotor position to provide a true infinite speed range, including full torque at zero speed.

The operation of PMSM motors requires position sensors in the rotor shaft when operated without damper winding. The ones most commonly used for motors are encoders and resolvers.

The speed control loop outputs the reference electromagnetic torque of the machine taken from an external source can be an analog signal and encoder feedback, or a serial command from a feedback device.

These PM drives use motor data and current measurements to calculate rotor position; the digital signal processor (DSP) calculations are quite accurate. During every sampling interval, the three-phase AC system dependent on time and speed is transformed into a rotating two-coordinate system in which every current is expressed and controlled as the sum of two vectors.

PMSM Drive-Vector Control Operation

PMSM Drive-Vector Control Operation

The reference direct and quadrature (dq) components of the stator current corresponding to the commanded torque are derived based on vector control strategy. The reference dq components of the stator current are then used to obtain the required gate signals for the inverter through a hysteresis-band current controller.

The main advantage of this drive compared to scalar-controlled drives is its fast dynamic response. The inherent coupling effect between the torque and flux in the machine is managed through decoupling (stator flux orientation) control, which allows the torque and flux to be controlled independently. However, due to its computation complexity, the implementation of this drive requires fast computing processors or DSPs.

Advantages of PMSM Motors over AC Induction Motors:

- PMSM has a high overload capability. The power-to-weight ratio of a PMSM is higher than induction machines.

- Higher efficiencies and smaller sizes (permanent magnet motors can be as much as one-third of most AC motor sizes, which makes installation and maintenance much easier) compared to Induction Motors.

- PMSMs’ ability to maintain full torque at low speeds.

- PMSM motors use magnets to produce the magnetic rotor field rather than the magnetizing component of the stator current like in the induction motor. These magnets consume almost no power, so copper losses are negligible level rotor unlike AC induction and Excited Synchronous motors.

- The rotor of PMSM has low electrical losses and dissipates less heat compared to an Induction motor. Also, friction is low and the durability is higher since no mechanical collectors and brushes to wear like induction motors.

- PMSM has low maintenance costs, durability, and reliability. For Brushless and mechanical switches, regular maintenance is significantly reduced and risks such as sparks in explosive or corrosive environments are eliminated.

- PMSM motors operate at an improved power factor, thereby improving the overall system power factor and eliminating or reducing utility power factor penalties. An improved power factor also reduces the system’s voltage drop and the voltage drop at the motor terminals.

Why are BLDC motors not suitable for Electric vehicles?

Switched or trapezoidal commutation in BLDC motors generates rotating waves (pulses) at low speed and hence BLDC motors are effective only in the range of high speeds.

The disadvantage of the BLDC motor is that there is a significant moment of pulses generated by the nonlinearity of the switching because only two motor windings are given current at any time. Nonlinearities generate noise and vibration.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)