Forklift Safety Tips & Rules for the Workplace, Texas Motive

The forklift is one of the most commonly used pieces of worksite equipment. It is used to lift and transport loads which can create operational risks. As a result, it’s very important that you and your crew are properly trained on forklift safety rules and forklift truck safety procedures.

Forklift accidents cause about 35,000 serious injuries and 85 fatalities every year. This is partly due to inadequate training.

This guide will cover the following:

- Forklift safety tips in the workplace

- Reach truck safety tips

- Forklift safety precautions

- Reach truck safety rules

- Forklift safety training

- And more

Mục Lục

Forklift Certification

One of the most important forklift safety tips to follow is to make sure you and all of your employees operating the forklift have forklift certification. Most accidents are due to inadequate training, so it’s crucial that only properly trained and licensed professionals operate a forklift. We recommend evaluating your employees’ performance regularly and supplementing their training and certification with videos, lectures, and demonstrations.

Wear Proper Clothing

All forklift operators should wear proper clothing and safety equipment, including hard hats, safety shoes, and a high visibility jacket. They should also tuck in any loose clothing to keep it from getting caught on the forklift.

Know the Forklift Class

One of the biggest safety rules for operating a forklift is knowing the forklift class. There are many distinct forklift classifications and types, and each type of forklift has its own weight limit, traveling speed, structure, turning radius, and usage. Therefore, it’s crucial you know the forklift class well in order to follow the proper safety practices for your specific type of forklift.

Inspect the Equipment

It’s also vital you inspect your equipment as often as possible, ideally every single day. We recommend thoroughly inspecting your forklift before every single use. Daily checks should be performed with a shift supervisor in order to identify and log any issues or defects with the forklift. Any equipment that needs repair should not be operated.

Be sure to check the test operating controls, including the lights, brakes, horn, and steering wheel, as well as the mast and overhead guard for damage. You should also examine the tire and fluid levels, check for water, oil, or radiator leaks, and ensure that the forks are in proper condition with no cracks or distortion. In addition, look for any other potential hazards.

Maintain Visibility

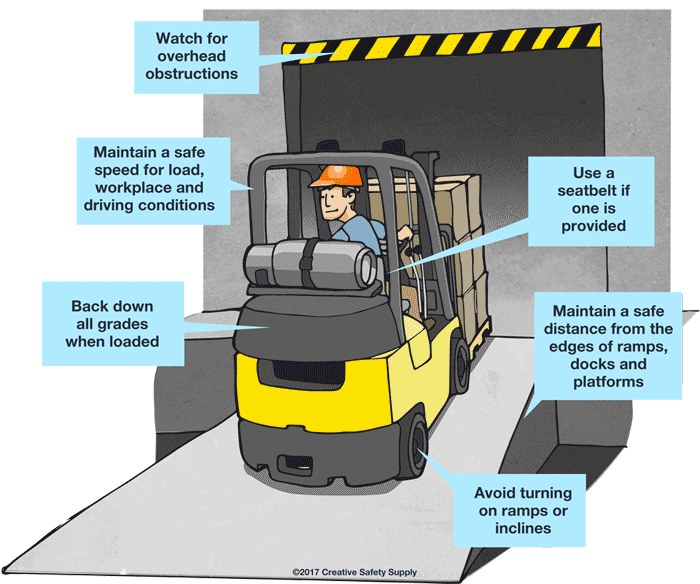

Another important forklift safety tip is to maintain 360-degree visibility by keeping the forks low to the ground. If a load is restricting your visibility, you should operate the equipment in reverse. Make sure you have a good view of the rack when you position the load. We also recommend always making eye contact with pedestrians and other workers, Moreover, look in the direction of travel, using rear-view mirrors to increase your visibility, and using headlights if you are working at night or in areas you need additional light.

Floor Marking System

You should use a floor marking system to improve worker safety. Use yellow to mark any physical hazards, including areas prone to stumbling or falling, and red to mark any fire hazards, fire equipment, and emergency switches. You can also place signs and wayfinders throughout the worksite to keep pedestrians away from forklift paths.

Make Sure Loads are Secure

When placing a load on the loading dock, we recommend checking the load for balance. Travel with the load tilted backward and keep forks as low as possible to improve stability, especially when driving on ramps.

Move at the Right Speed

You should drive your forklift within the appropriate speed limits and make sure not to stop, turn, or change directions suddenly since these actions can cause the forklift to tip over. If your forklift does start to tip over, don’t try to jump away from the machine. Instead, stay in the vehicle, grip the wheel, and brace your feet.

Maintain a Safe Distance

Always be very mindful of the surrounding equipment on the worksite, and don’t operate your forklift near other machinery unless absolutely necessary. Keeping a safe distance will enhance the safety of all as you’ll have room to stop when required.

Avoid Hazardous Areas

Avoid standing or walking under a load, forklift attachment, or lifting mechanism, since loads can fall off a forklift onto anyone positioned under it. Keep your hands and feet away from the forklift mast since a moving mast can cause serious injury.

Refuel and Recharge the Forklift

We also recommend keeping your forklift equipment fully fueled and charged. Make sure to refuel and recharge the forklift in designated locations, which tend to be flame-free and well-ventilated areas. It’s very important to be as diligent as possible about switching off the forklift equipment each and every time you refuel it.

Contact Texas Motive Solutions

If you want more information about forklift safety, contact Texas Motive Solutions. In addition to answers about forklift safety, we offer a free forklift performance analysis that can provide you with solutions for your business.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)