EV Motors Explained

From the April 2022 issue of Car and Driver.

Automobile lovers have been steeped in the language of the internal-combustion engine for so long that the inexorable switch to electrification requires a tune-up of our knowledge base. Many of us are familiar with the suck-squeeze-bang-blow rhythm of the four-cycle engine that powers the majority of today’s daily drivers, while the snowmobilers and outboard enthusiasts among us can probably explain the inner workings of a two-stroke. A few nerds may even have a handle on the epitrochoidal machinations of the Wankel rotary, but the average gearhead’s experience with electric motors might just begin and end with the last time their starter conked out.

All types of electric-vehicle motors share two major parts. The stator is the motor’s stationary outer shell, whose housing is mounted to the chassis like an engine block. The rotor is the lone rotating element and is analogous to a crankshaft in that it feeds torque out through the transmission and onto a differential.

Most EVs rely on a direct-drive (single-ratio) unit to step down the rotating speed between the motor and the wheels. Like internal-combustion engines, electric motors are most efficient at low rpm and higher load. While an electric car might enjoy an acceptable driving range with a single gear, heavier pickups and SUVs designed to pull trailers will increase range with a multi-speed transmission at highway speed. Today only the Audi e-tron GT and Porsche Taycan use a two-speed transmission. Multi-gear (spin) losses and development costs are reasons why EVs with more than one gear are uncommon, but we predict that will change.

EV Motor Commonality

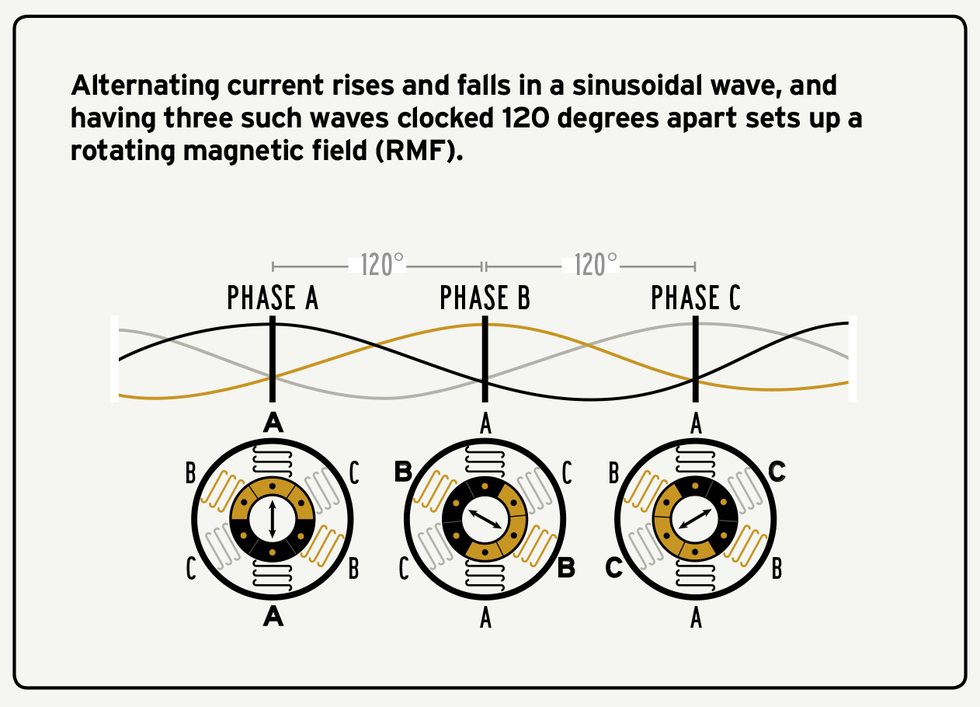

All three major EV motor types use three-phase alternating current to set up a rotating magnetic field (RMF), the frequency and power of which are controlled by the power electronics that respond to the accelerator. Stators contain numerous parallel slots stuffed with interconnected loops of copper windings. These can be bulky looms of round copper wire or tidy hairpin-shaped copper insertions with square cross-sections that increase both fill density and direct wire-to-wire contact within the grooves. Denser windings improve torque capability, and tidier interlacing at the ends amounts to less bulk and a smaller overall package.

Batteries are direct-current (DC) devices, so an EV’s power electronics include a DC-AC inverter to provide the stator with the AC current necessary to create the all-important variable RMF. But it’s worth pointing out that these electric motors are also generators, which means that wheels will back-drive the rotor within the stator to induce an RMF in the other direction that feeds power back through the now AC-DC converter to send power into the battery. This process, known as regenerative braking, creates drag that slows the vehicle. Regen is not only central to extending an electric car’s range, it’s pretty much the whole ball of wax when it comes to highly efficient hybrids because lots of regen improves the EPA fuel-economy numbers. But in the real world, regen is less efficient than coasting, which avoids the losses each time the energy passes through the motor and converter when harvesting kinetic energy.

The Three EV Motor Types

The motor types can be broken down by fundamental rotor differences that represent entirely different ways of turning the stator’s RMF into actual rotary motion. These differences are stark enough, in fact, that they do justice to our original four-cycle, two-cycle, and Wankel analogy. In the asynchronous category, we have induction motors, while the synchronous group contains permanent-magnet and current-excited motors.

Induction motors have been around since the 19th century. Here the rotor contains longitudinal laminations or bars of conductive material, most often copper but sometimes aluminum. The stator’s RMF induces a current in these laminations, which in turn creates an electromagnetic field (EMF) that begins to rotate within the stator’s RMF. Induction motors are known as asynchronous motors because the induced EMF and the rotating torque that comes with it can exist only when the rotor’s speed lags behind the RMF. Such motors are common because they have no need for rare-earth magnets and are relatively cheap to manufacture, but they can be harder to cool at sustained high loads and are inherently less efficient at low speeds.

As the name implies, the rotors in permanent-magnet motors possess their own magnetism. No power is needed to create the rotor’s magnetic field, making them far more efficient at low speed. Such rotors also turn in lock-step with the stator’s RMF, making them synchronous. But there are problems with simply wrapping a rotor with surface-mounted magnets. This requires larger magnets, for one, and keeping a rotor together at high speed becomes more difficult as things get heavier. But the bigger problem is the so-called “back EMF” at high speeds, in which a reverse-induced electromagnetic magnetic field adds drag that limits top-end power and creates excess heat that can damage the magnets.

To combat this, most EV permanent-magnet motors feature internally mounted permanent magnets (IPM) that are slid in pairs into lengthwise V-shaped slots arrayed in multiple lobes just under the surface of the rotor’s iron core. The slots keep the IPMs secure at high speed, but the deliberately shaped areas between the magnets create a reluctance torque. Magnets are either attracted to or repelled by other magnets, but ordinary reluctance, the force that sticks a magnet to a toolbox, attracts the lobes of the iron rotor to the RMF. IPMs do the work at lower speeds, and the reluctance torque takes over at high speeds. Lest you think this is new, the Prius uses them.

The final type of motor didn’t exist in EVs until recently because conventional wisdom held that brushless motors, which describes the motors above, were the only viable option for an electric vehicle. BMW recently bucked this trend by fitting brushed current-excited AC synchronous motors to the new i4 and iX. This type’s rotor interacts with the stator’s RMF exactly the same as a permanent-magnet rotor, but the rotor lacks permanent magnets. Instead, it features six broad copper lobes energized with DC battery power to create the necessary EMF. Pulling this off takes slip rings and spring-loaded brushes on the rotor shaft, which has led others to avoid this approach over concerns about brush wear and its associated dust. Will brush wear be an issue here? That remains to be seen, but we doubt it. The brush array is sequestered in an isolated compartment, with a removable cover enabling easy access. The lack of permanent magnets avoids the issues of rising rare-earth costs and the environmental impact of mining. This scheme also makes it possible to vary the strength of the rotor’s magnetic field, which enables further optimization. Still, power is required to energize this rotor, making these motors less efficient, notably at low speeds when the energy needed to create the field represents a greater percentage of the total consumption.

The appearance of the current-excited AC synchronous motor is so recent in the short history of EVs that it illustrates just how early we are in the development curve. There’s abundant room for fresh ideas, and there have already been major pivots, not least including Tesla’s move away from the induction-motor concept that is the basis for its own brand name and logo and toward permanent-magnet synchronous motors. And we’re barely a decade into the modern EV era—we’re just getting started.

Car and Driver

Dan Edmunds

Technical Editor

Dan Edmunds was born into the world of automobiles, but not how you might think. His father was a retired racing driver who opened Autoresearch, a race-car-building shop, where Dan cut his teeth as a metal fabricator. Engineering school followed, then SCCA Showroom Stock racing, and that combination landed him suspension development jobs at two different automakers. His writing career began when he was picked up by Edmunds.com (no relation) to build a testing department.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)