Electrical Wires & Cables – D & F Liquidators

Electrical Wires & Cables

Mục Lục

Table of Content

More often than not, the terms wire and cable are used to describe the same thing, but they are actually quite different. Wire is a single electrical conductor, whereas a cable is a group of wires swathed in sheathing. The term cable originally referred to a nautical line of multiple ropes used to anchor ships, and in an electrical context, cables (like wires) are used to carry electrical currents.

Whether indoors or outdoors, proper wire and cable installation is of paramount importance – ensuring a smooth electricity supply, as well as passing electrical inspections. Each wire and cable needs to be installed carefully, from the fuse box to the outlets, fixtures and appliances. The National Electrical Code (NEC) and Local Building Codes regulate the manner of installation and the types of wires and cables for various electrical applications.

Understanding Electrical Wire

Some factors that will affect your choice of electrical wiring include color, label information and applications. The information printed on the electrical wire covering is all that you need to choose the correct wire for your home. Here’s some detailed information on the various features of electrical wire, which will help you choose the correct composition:

1. Size of Wires

Each application requires a certain wire size for installation, and the right size for a specific application is determined by the wire gauge. Sizing of wire is done by the American wire gauge system. Common wire sizes are 10, 12 and 14 – a higher number means a smaller wire size, and affects the amount of power it can carry. For example, a low-voltage lamp cord with 10 Amps will require 18-gauge wire, while service panels or subpanels with 100 Amps will require 2-gauge wire.

2. Wire Lettering

The letters THHN, THWN, THW and XHHN represent the main insulation types of individual wires. These letters depict the following NEC requirements:.

- T – Thermoplastic insulation

- H – Heat resistance

- HH – High heat resistance (up to 194°F)

- W – Suitable for wet locations

- N – Nylon coating, resistant to damage by oil or gas

- X – Synthetic polymer that is flame-resistant

3. Types of Electrical Wire

There are mainly 5 types of wire: .

- Triplex Wires : Triplex wires are usually used in single-phase service drop conductors, between the power pole and weather heads. They are composed of two insulated aluminum wires wrapped with a third bare wire which is used as a common neutral. The neutral is usually of a smaller gauge and grounded at both the electric meter and the transformer.

- Main Feeder Wires : Main power feeder wires are the wires that connect the service weather head to the house. They’re made with stranded or solid THHN wire and the cable installed is 25% more than the load required.

- Panel Feed Wires : Panel feed cables are generally black insulated THHN wire. These are used to power the main junction box and the circuit breaker panels. Just like main power feeder wires, the cables should be rated for 25% more than the actual load.

- Non-Metallic Sheathed Wires : Non-metallic sheath wire, or Romex, is used in most homes and has 2-3 conductors, each with plastic insulation, and a bare ground wire. The individual wires are covered with another layer of non-metallic sheathing. Since it’s relatively cheaper and available in ratings for 15, 20 and 20 amps, this type is preferred for in-house wiring.

- Single Strand Wires : Single strand wire also uses THHN wire, though there are other variants. Each wire is separate and multiple wires can be drawn together through a pipe easily. Single strand wires are the most popular choice for layouts that use pipes to contain wires.

4. Color Codes

Different color wires serve different purposes, like:.

- Black : Hot wire, for switches or outlets.

- Red : Hot wire, for switch legs. Also for connecting wire between 2 hardwired smoke detectors.

- Blue and Yellow : Hot wires, pulled in conduit. Blue for 3-4 way switch application, and yellow for switch legs to control fan, lights etc.

- White : Always neutral.

- Green and Bare Copper : Only for grounding.

5. Wire Gauge, Ampacity and Wattage Load

To determine the correct wire, it is important to understand what ampacity and wattage a wire can carry per gauge. Wire gauge is the size of the wire, ampacity is how much electricity can flow through the wire and wattage is the load a wire can take, which is always mentioned on the appliances..

Wire Types + Uses . Video by Neepawa GG

Understanding Electrical Cable

Wire Types + Uses . Video by

An electrical cable also has different types, color and application as its determining factors. Here’s a brief about cables that you need to understand to determine the correct cable for your home.

1. Types of Electrical Cables

There are more than 20 different types of cables available today, designed for applications ranging from transmission to heavy industrial use. Some of the most commonly-used ones include:

- Non-Metallic Sheathed Cable : These cables are also known as non-metallic building wire or NM cables. They feature a flexible plastic jacket with two to four wires (TECK cables are covered with thermoplastic insulation) and a bare wire for grounding. Special varieties of this cable are used for underground or outdoor use, but NM-B and NM-C non-metallic sheathed cables are the most common form of indoor residential cabling.

- Underground Feeder Cable : These cables are quite similar to NM cables, but instead of each wire being individually wrapped in thermoplastic, wires are grouped together and embedded in the flexible material. Available in a variety of gauge sizes, UF cables are often used for outdoor lighting and in-ground applications. Their high water-resistance makes them ideal for damp areas like gardens as well as open-to-air lamps, pumps, etc.

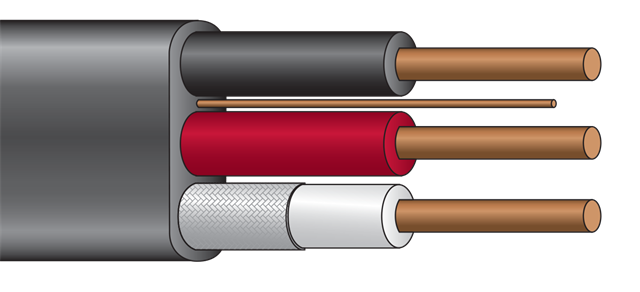

- Metallic Sheathed Cable : Also known as armored or BX cables, metal-sheathed cables are often used to supply mains electricity or for large appliances. They feature three plain stranded copper wires (one wire for the current, one grounding wire and one neutral wire) that are insulated with cross-linked polyethylene, PVC bedding and a black PVC sheathing. BX cables with steel wire sheathing are often used for outdoor applications and high-stress installations.

- Multi-Conductor Cable : This is a cable type that is commonly used in homes, since it is simple to use and well-insulated. Multi-conductor or multi-core (MC) cables feature more than one conductor, each of which is insulated individually. In addition, an outer insulation layer is added for extra security. Different varieties are used in industries, like the audio multicore ‘snake cable’ used in the music industry.

- Coaxial Cable : A coaxial (sometimes heliax) cable features a tubular insulating layer that protects an inner conductor which is further surrounded by a tubular conducting shield, and might also feature an outer sheath for extra insulation. Called ‘coaxial’ since the two inner shields share the same geometric axis, these cables are normally used for carrying television signals and connecting video equipment.

- Unshielded Twisted Pair Cable : Like the name suggests, this type consists of two wires that are twisted together. The individual wires are not insulated, which makes this cable perfect for signal transmission and video applications. Since they are more affordable than coaxial or optical fiber cables, UTP cables are often used in telephones, security cameras and data networks. For indoor use, UTP cables with copper wires or solid copper cores are a popular choice, since they are flexible and can be easily bent for in-wall installation.

- Ribbon Cable : Ribbon cables are often used in computers and peripherals, with various conducting wires that run parallel to each other on a flat plane, leading to a visual resemblance to flat ribbons. These cables are quite flexible and can only handle low voltage applications.

- Direct-Buried Cable : Also known as DBCs, these cables are specially-designed coaxial or bundled fiber-optic cables, which do not require any added sheathing, insulation or piping before being buried underground. They feature a heavy metal core with many layers of banded metal sheathing, heavy rubber coverings, shock-absorbing gel and waterproof wrapped thread-fortified tape. High tolerance to temperature changes, moisture and other environmental factors makes them a popular choice for transmission or communication requirements.

- Twin-Lead Cable : These are flat two-wire cables that are used for transmission between an antenna and receiver, like TV and radio.

- Twinaxial Cable : This is a variant of coaxial cables, which features two inner conductors instead of one and is used for very-short-range high-speed signals.

- Paired Cable : With two individually insulated conductors, this cable is normally used in DC or low-frequency AC applications.

- Twisted Pair : This cable is similar to paired cables, but the inner insulated wires are twisted or intertwined.

2. Cable Color Code

Color coding of cable insulation is done to determine active, neutral and earth conductors. The NEC has not prescribed any color for phase/active conductors. Different countries/regions have different cable color coding, and it is essential to know what is applicable in your region. However, active conductors cannot be green/yellow, green, yellow, light blue or black..

3. Cable Size

Cable size is the gauge of individual wires within the cable, such as 14, 12, 10 etc. – again, the bigger the number, the smaller the size. The number of wires follows the wire-gauge on a cable. So, 10/3 would indicate the presence of 3 wires of 10-gauge within the cable. Ground wire, if present, is not indicated by this number, and is represented by the letter ‘G’.

Safety is very important, and if your installation of wires and cables is not proper, it could lead to accidents. Before you start any electrical project that includes wiring and cabling, you need to obtain permission from your local building inspector. Once the job is done, get the installation inspected for compliance with local codes and regulations.

Contact Us

If you have any questions please contact us by phone, fax, email or by completing our online contact form.

Contact Us

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)