Electric Cylinder Manufacturers Suppliers

Mục Lục

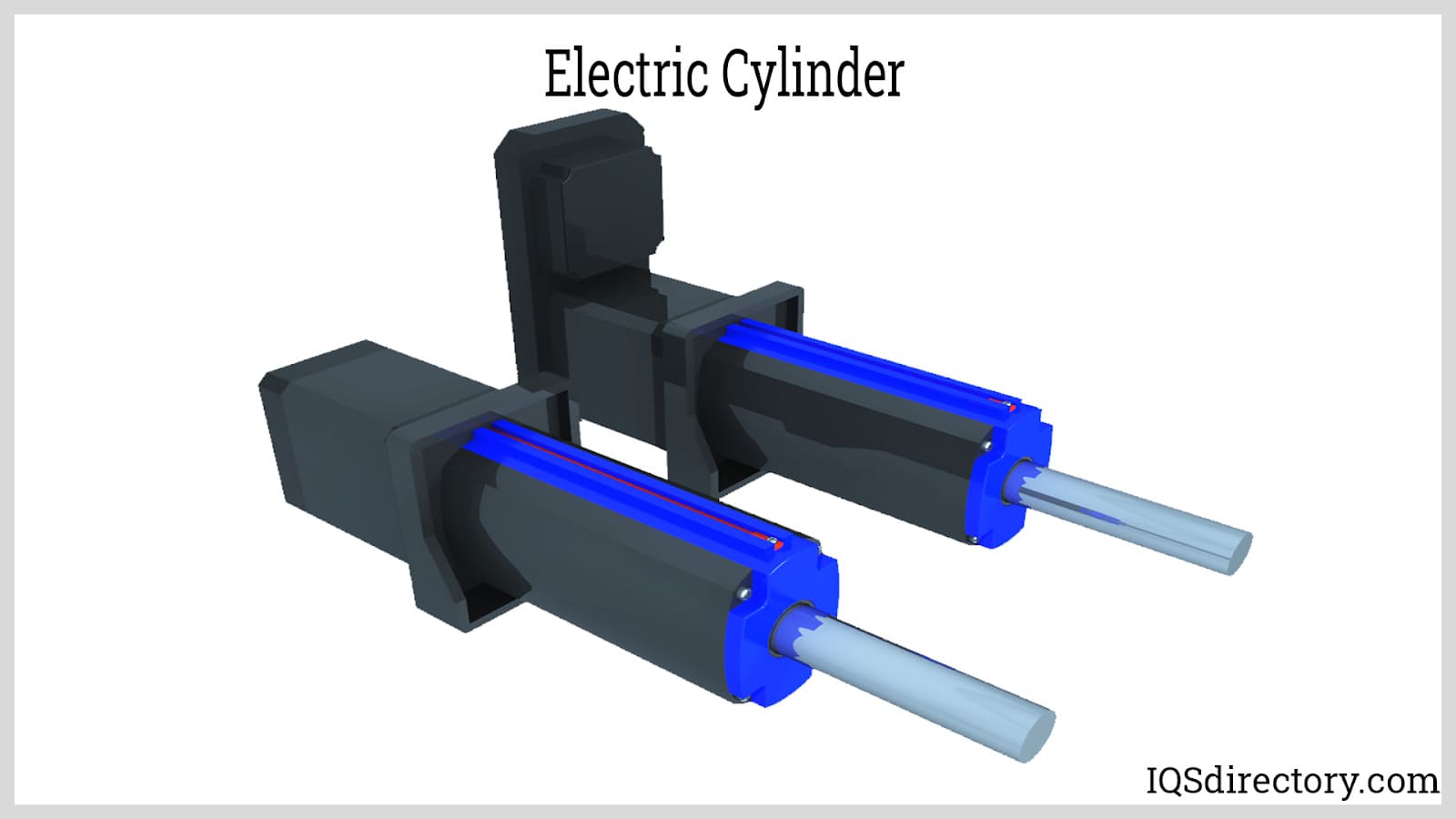

What are Electric Cylinders?

These cylinders are rapidly replacing pneumatic cylinders in many industries due to their enhanced motion control, lower maintenance cost, and a long list of added advantages.

Electric cylinders are linear motion products that are extremely versatile. They provide anti-rotation features ideal for z-theta, dual-axis, and z-axis designs, as well as internal guiding.

Electric cylinders also have another unique feature: the tubular structure, which protects the ball screw or lead screw from dirt, dust, and other environmental conditions, permitting it to be used in harsh conditions.

How Electric Cylinders Work

Electric cylinders have a basic logic of providing useful work by converting the rotary motion of a drive element into linear motion. The models of electric cylinders vary according to the type of motor that will be responsible for providing rotational motion, the shaft screw type that is responsible for providing linear motion, and the types of connections that will allow the combining of these two components.

Electric cylinders have a mechanical structure and are separated from other systems. The movement in these cylinders is provided by a shaft screw placed in a body. The ball screw enables the transfer of power by converting the rotary motion it receives from the motor into a linear motion.

High-speed control, position precision, and force control are provided depending on the mechanical products used in the electric cylinders and the type of engine used.

Types of Electric Cylinders

The different types of electric cylinders include:

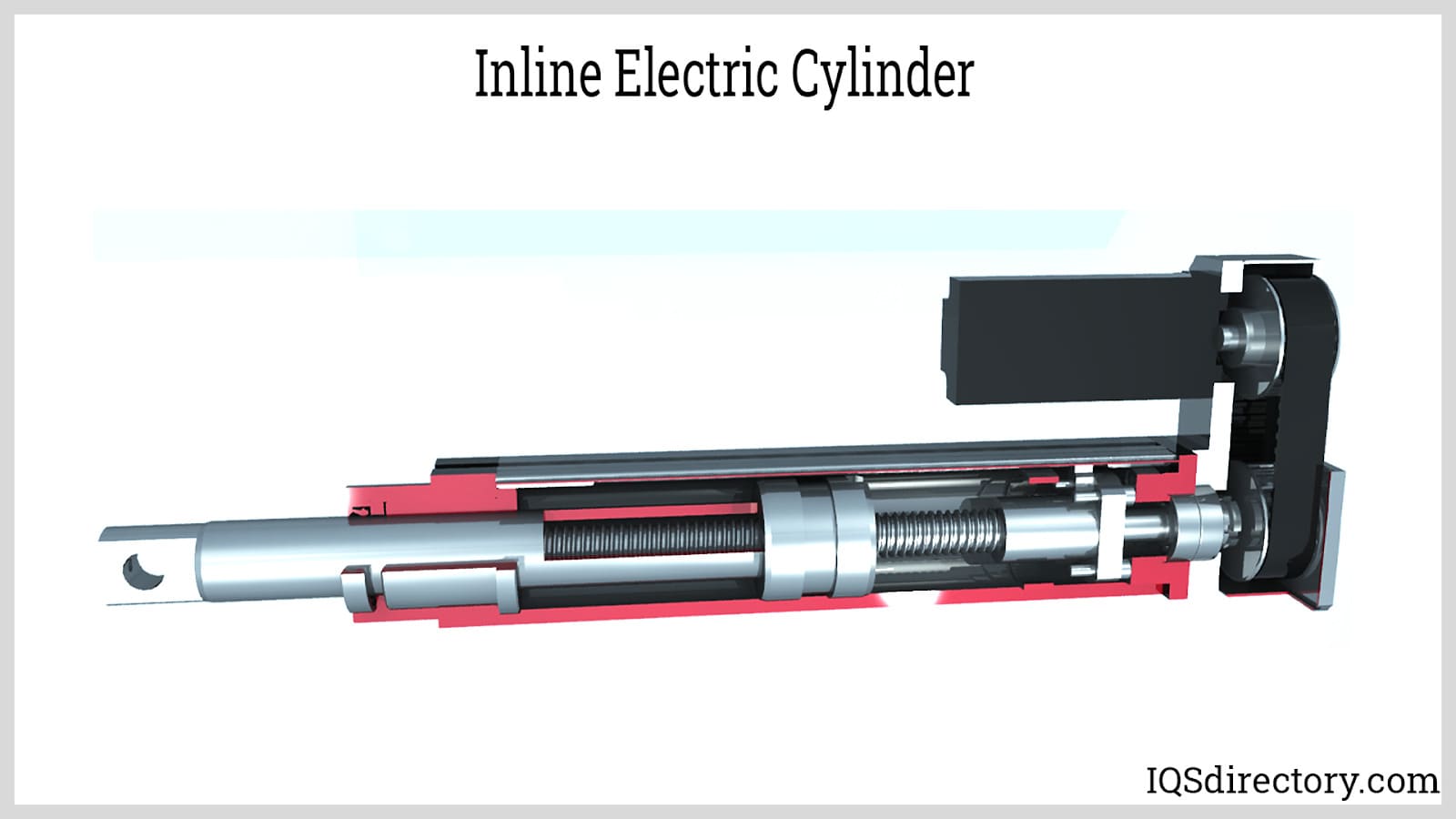

Inline Type Electric Cylinder

This type of electric cylinder has a motor that is directly connected to the electric cylinder via a coupling.

Structure

The body of the electric cylinder and the motor are in the same line, and this type of electric cylinder integrates the servo motor encoder, the servo motor, the modular design, the planetary ball screw, and the high precision ball screw, the trapezoidal screw, and other technologies.

Features

The entire electric cylinder exhibits small inertia, compact structure, fast response, low noise, high rigidity, and long life.

Installation

Connection is made from the servo motor to the electric cylinder as a whole, which is simple to set up and easy to install.

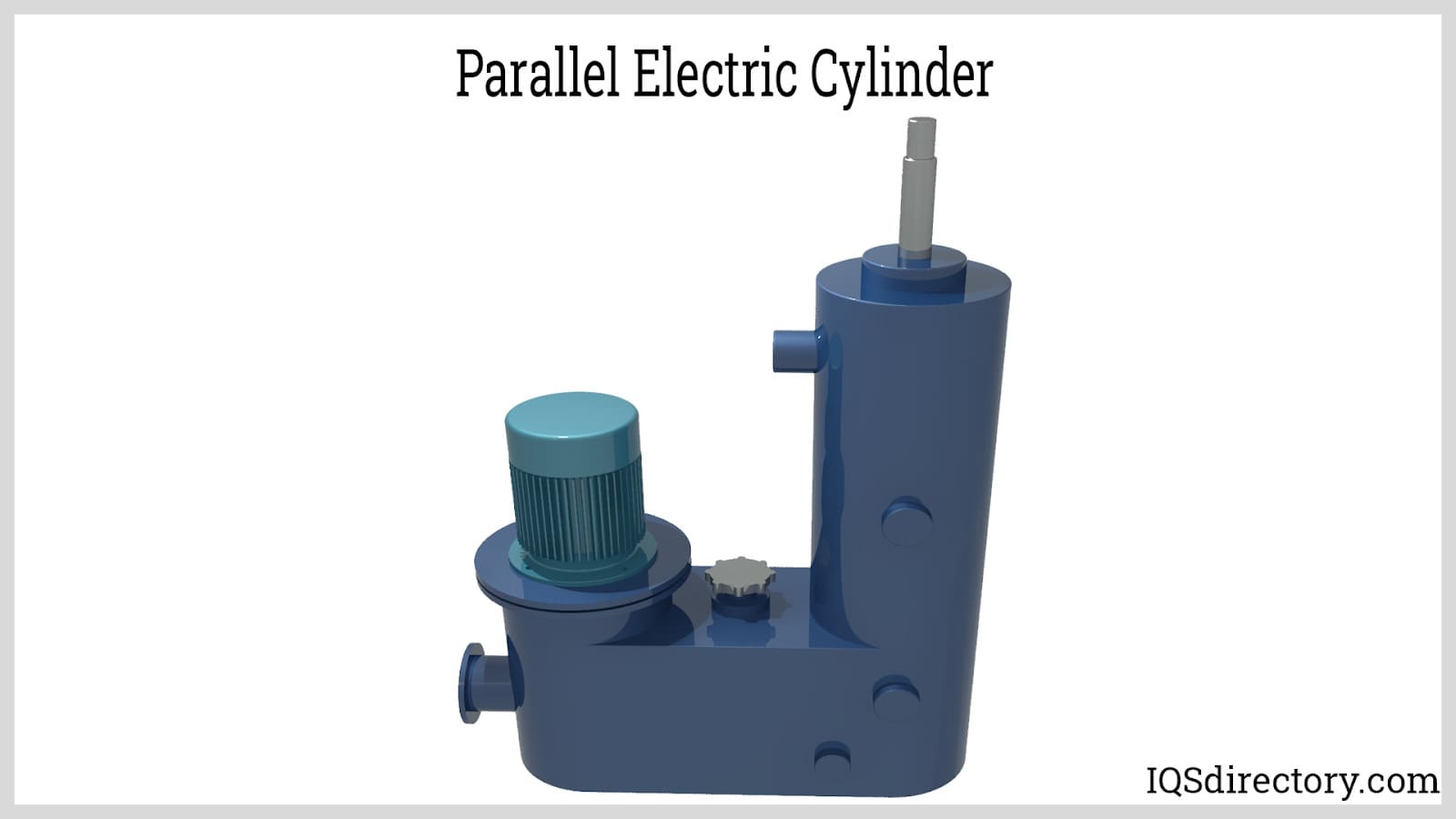

Parallel Type Electric Cylinder

The installation of a parallel electric cylinder’s motor is parallel to the body of the cylinder. The motor’s motion is transmitted to the ball screw motion through the timing belt and a synchronous pulley.

Features

Shorter length: to add on top of the characteristics of the inline type electric cylinder, the parallel type electric cylinder has a relatively shorter length, which enables the parallel type electric cylinder to fit more for installation in a limited space.

High strength

The timing belt used in parallel electric cylinders exhibits high strength and has a long service life. This makes the entire electric cylinder have high and accurate controllability.

Adjustable Gear Ratio

Parallel electric cylinders have adjustable gear ratios. This means that the dimension ratio of the synchronous pulley can be adjusted to increase the thrust and lower the speed, which is suitable for those that require large thrust but reduced speed, like lifting devices, presses, etc.

Applications, Benefits of Electric Cylinders

The applications and benefits of electric cylinders include:

Applications of Electric Cylinders

- The entertainment industry. Electric cylinders are used in multi-degree freedom dynamic entertainment, joint dynamic, robot arm, dynamic seat, multi-degrees of freedom simulation, etc.

- Iron and steel industry. They are mostly used in the unloading of coal, in belt conveyors, ash unloading, ore unloading, and dust collecting devices, and in working places like raw material terminals, sintering plants, raw material plants, cooking plants, steelworks, ironworks, etc.

- Automotive industry. They are used in automotive manufacturing equipment and automotive presses.

- Military industry. They are used in simulation and analog aircraft.

- Other industrial industries. They are used in petrochemicals, injection molding machines, automation production lines, material handling, valve control, mold control, pharmaceutical machinery, precision machine tools, mechanical lifting platforms, the food industry, etc.

Benefits of Electric Cylinders

- Accurate control of position, force, and speed

- Small size

- Multiple axes can be synchronized easily

- Increased efficiency compared to hydraulic systems

- Reduced energy consumption

- No use of hazardous fire resistance fluids or oil

- Ideal for clean and high-temperature application environments

- Long-lasting

- Easy installation

- Smooth and quiet operation

- Highly customizable

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)