Electric Arc Furnace vs. Blast Furnace

September 11, 2020

As you know, steel is our favorite subject. All the steel we sell is produced by these two types of furnaces.

Do you know the differences between the Electric Arc Furnace and the Blast Furnace? There are benefits and challenges to each, so we will explain the advantages and disadvantages of each one.

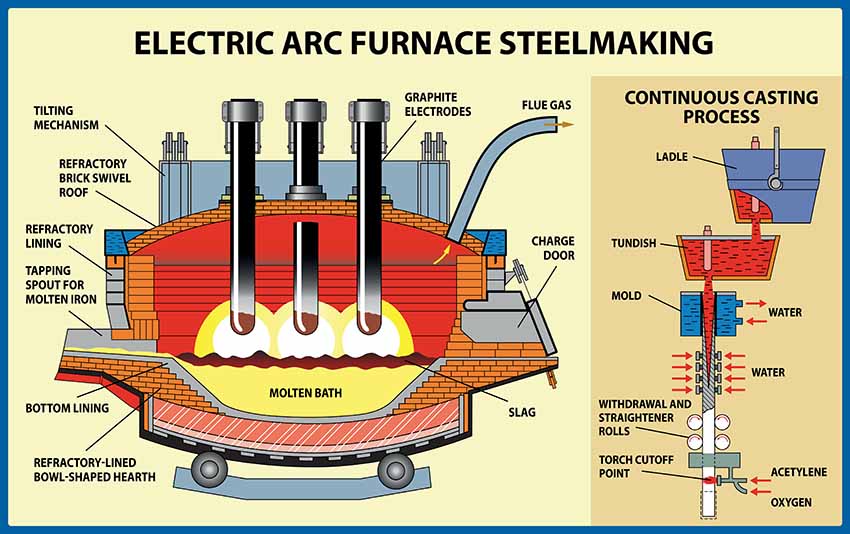

Electric arc furnace

- Uses obsolescent scrap as the main source of material.

- Uses electricity as its main source of energy to melt scrap and adjust the properties in a ladle furnace.

- Lower initial costs and takes up less space.

- Take less time to manufacture products.

The Electric arc furnace is smaller and more efficient. They do not require a constant coke supply; instead, they use electricity carried through graphite electrodes to create an arc. The metal used with an Electric arc furnace is usually scrap steel. Managing the temperature within the system is easier than a blast furnace, making it more efficient. Another benefit of using the EAF process is that all types of steel can be created.

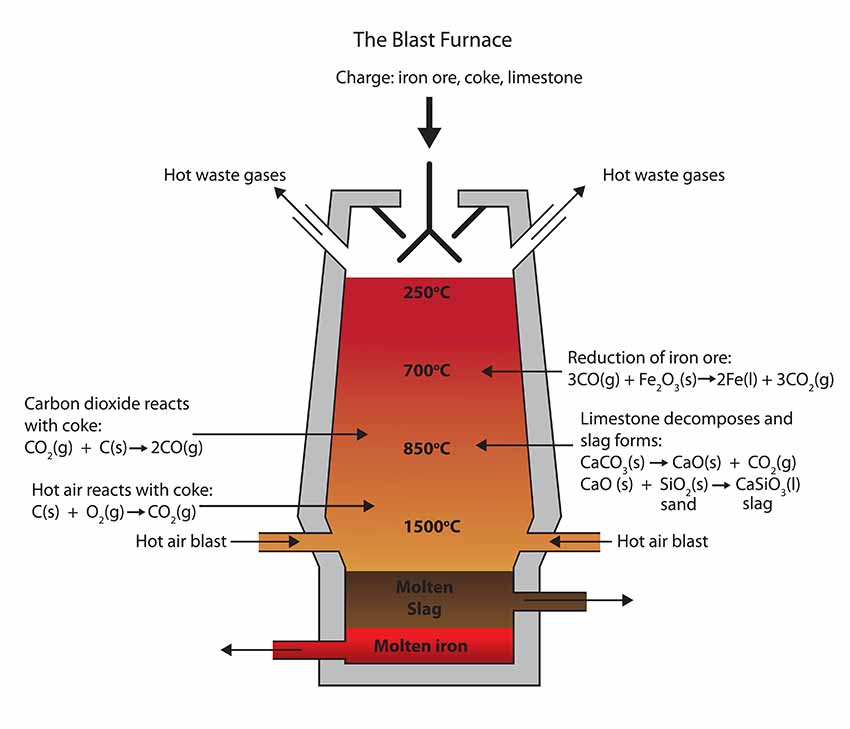

Blast furnace

- Uses iron ore as the source of material and coke as the main fuel and sources of energy.

- Melts iron ore and coke so it can produce pig iron high in carbon content and this is then is fed into a converter to remove impurities.

- Needs a high investment in facility development and takes up a large space.

- Easier to produce clean steel.

- Emits a large amount of carbon dioxide.

The blast furnace symbolizes the metal industry as most know it. We see this in photos as a huge furnace system, and it involves multiple components.

Coke is utilized to melt the iron ore to create pig iron. Oxygen is then used to transform the pig iron into steel. However, this method produces high CO2 emissions because of the continual requirement of coke.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)