Electric Actuators: Types, Applications, Benefits, and Design

Mục Lục

Electric Actuators

Contact Companies

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Get Your Company Listed on this Power Page

Introduction

This article will take an in-depth look at electric actuators.

The article will bring more detail on topics such as:

- Principle of Electric Actuators

- Types of Electric Actuators

- Applications & Benefits of Electric Actuators

- And Much More…

Chapter 1: Principle of Electric Actuators

This chapter will discuss what electric actuators are, their manufacturing and components, how they function, and their efficiency.

What are Electric Actuators?

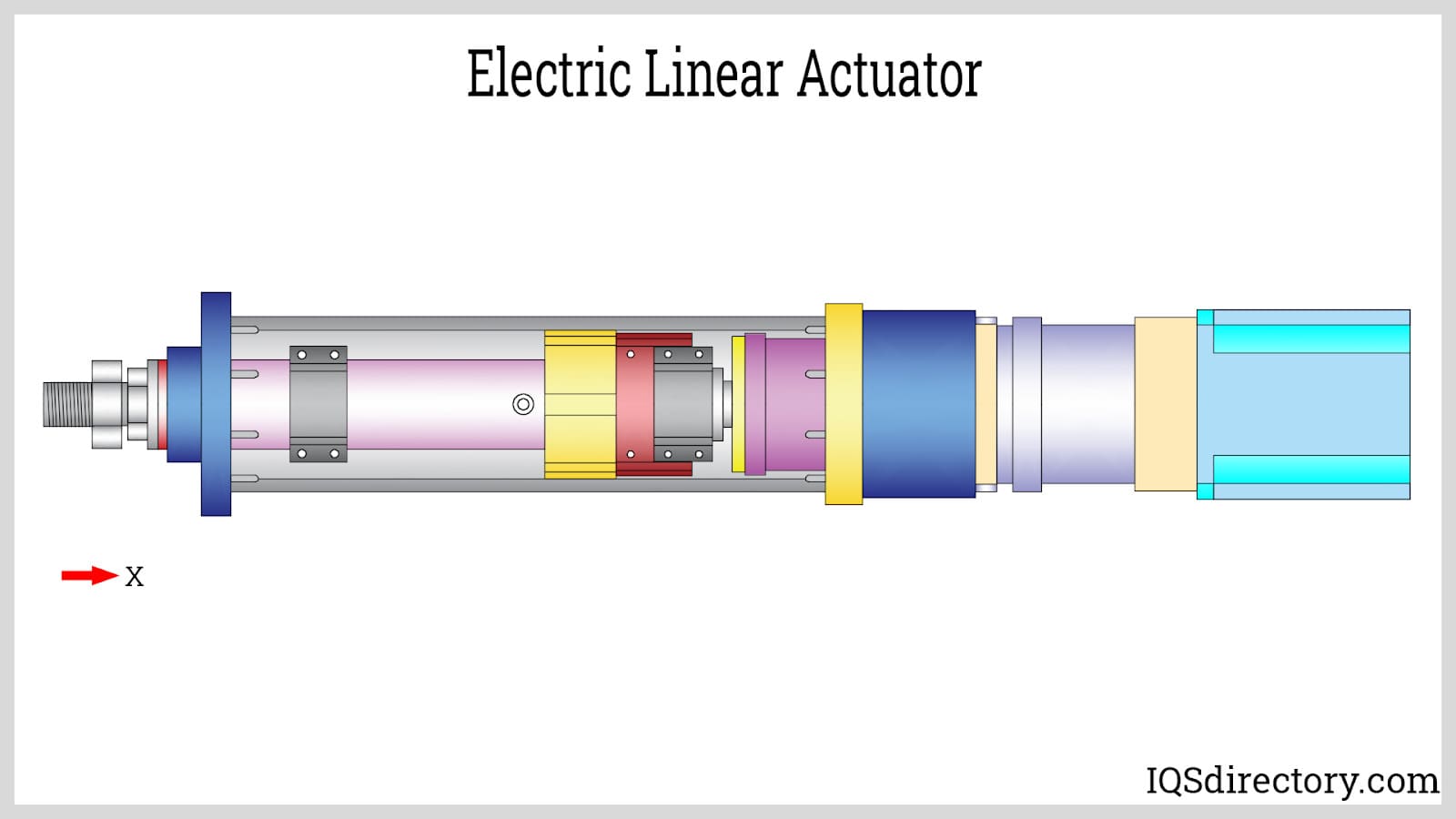

Electric actuators are devices capable of creating motion of a load, or an action that requires a force like clamping, making use of an electric motor to create the force that is necessary.

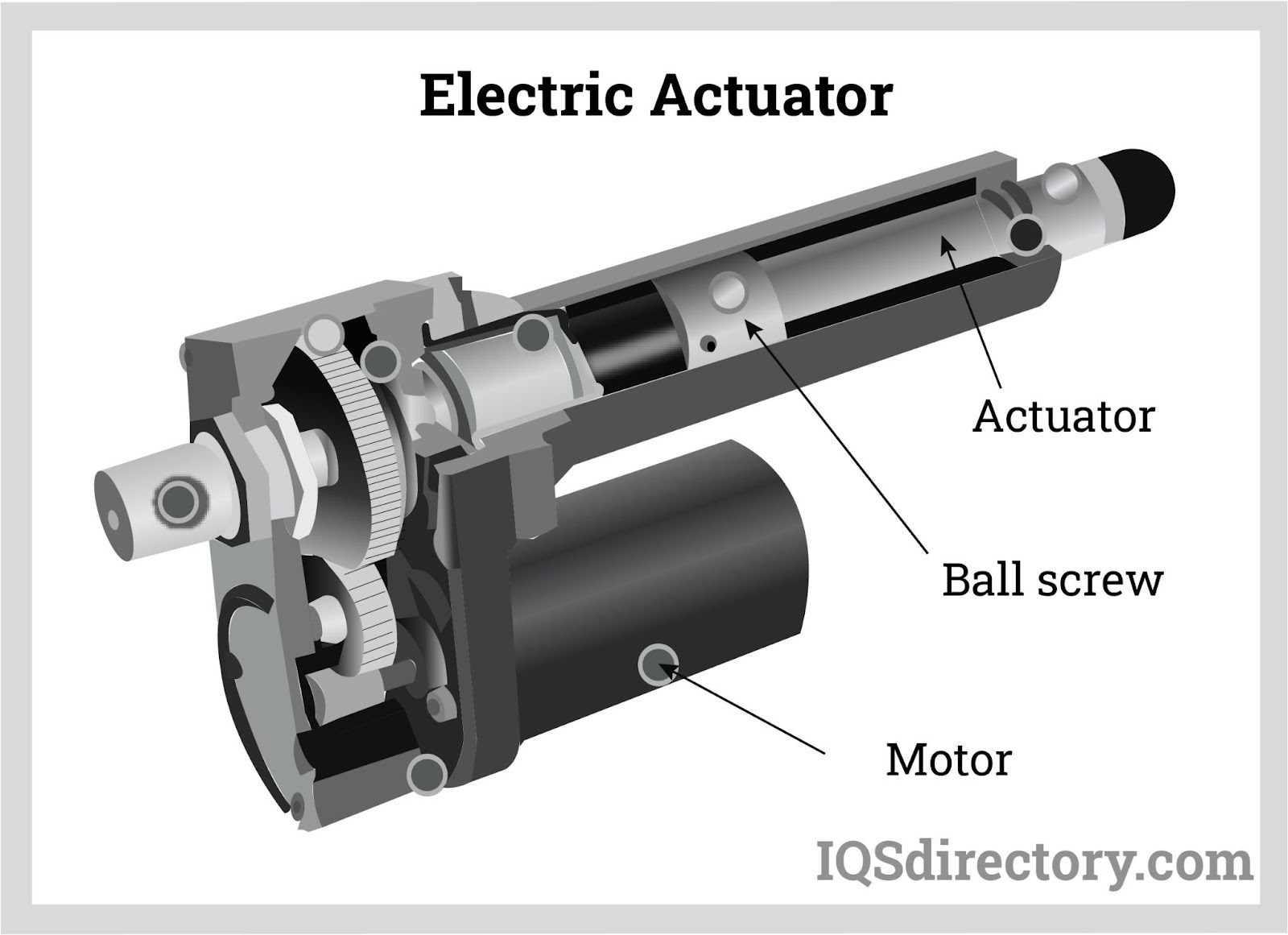

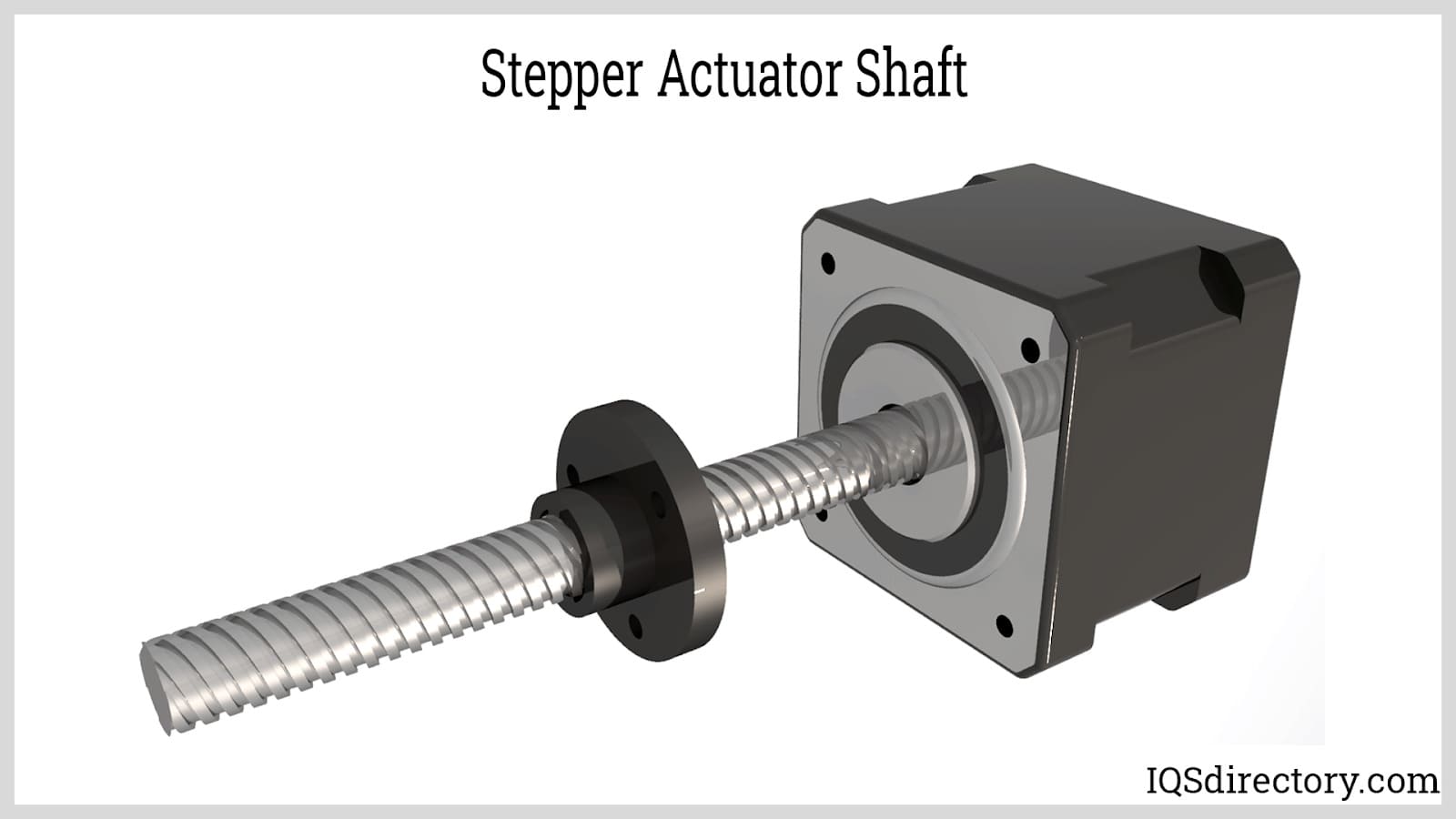

As the spindle or rotor rotates, rotary motion is created by an electric motor. In the structure of an electrical actuator, there is a helical screw to which the motor spindle is coupled via the drive shaft. This will rotate in a ball screw nut.

Manufacturing Electric Actuators

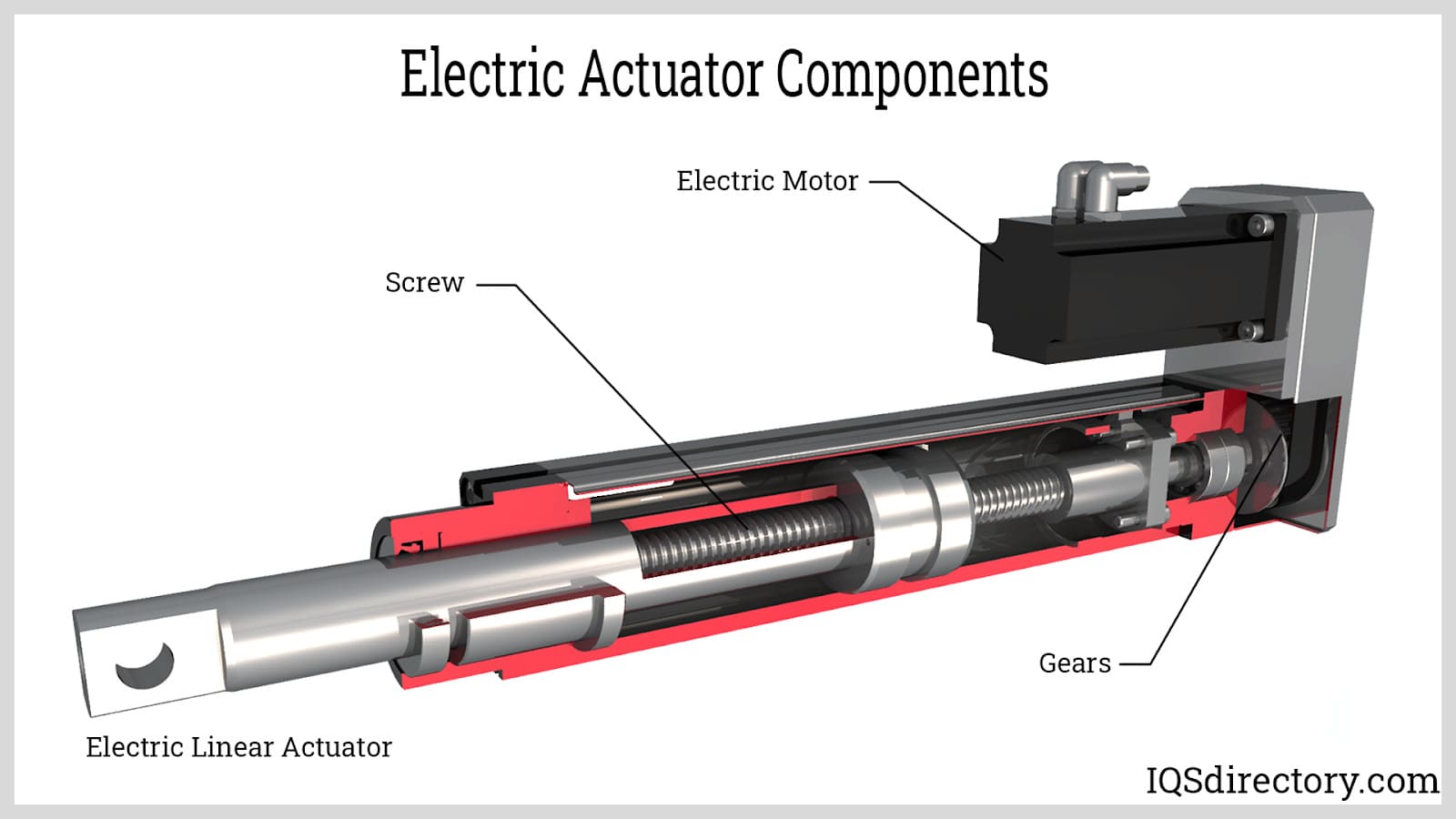

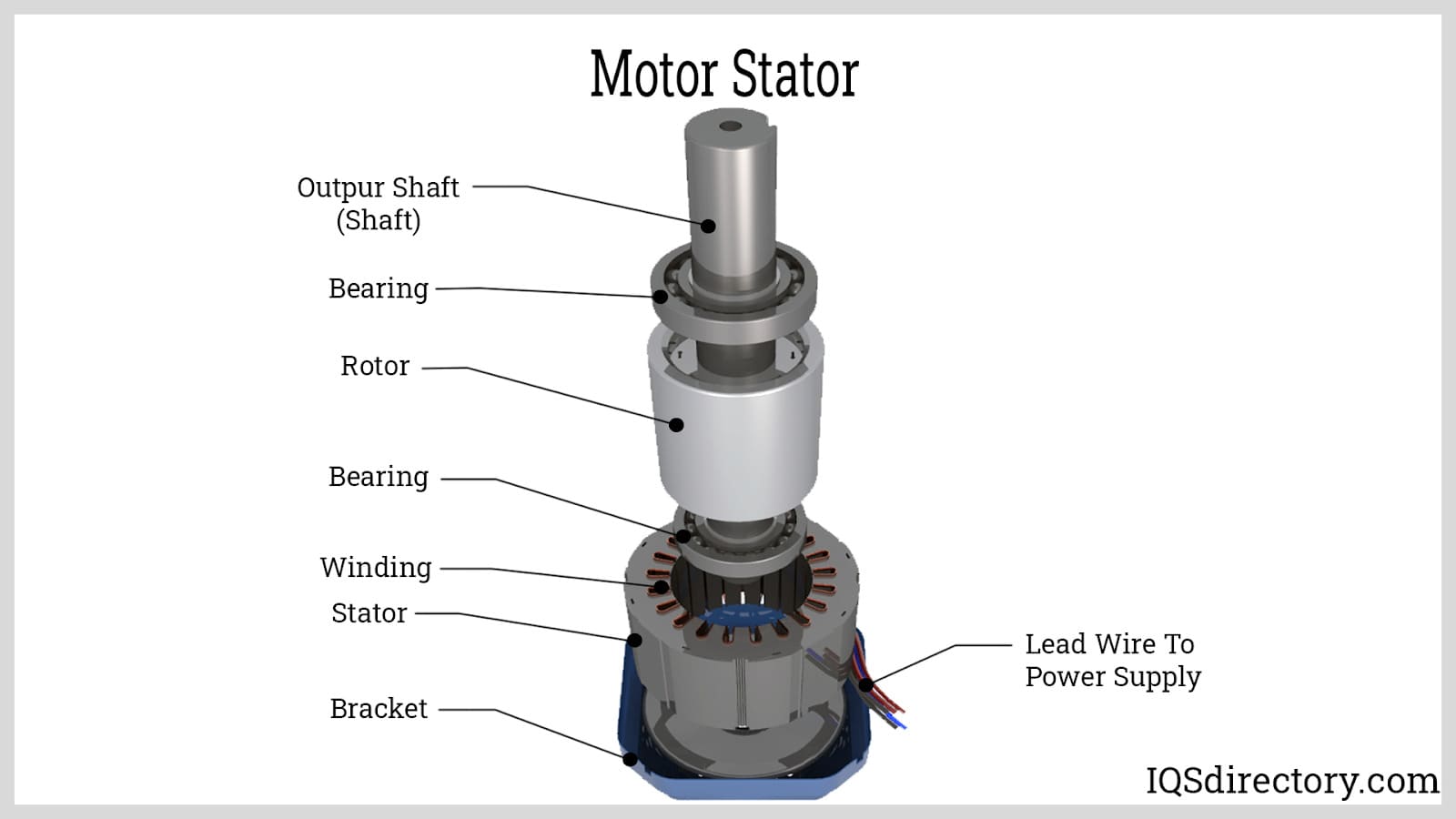

To produce an electric linear actuator, the manufacturing process begins with the electric motor. Each electric motor consists of two main components which are: Stator – a permanent magnet that is stationary; Rotor – sits in the center of the stator and is forced to undergo the magnetic field generated by the stator, thereby causing a spin in motion of the rotor.

Each part is crafted carefully from an assembly line that is within the electric linear actuator factory that is fully automated. Every step is monitored, from the copper coils wounded on the rotor, to the insertion of the shaft screw into the motor. Each batch is carefully examined by the quality assurance experts. There is a concurrent production of different parts of the motors to optimize the assembly line of each linear actuator.

The raw materials and finished parts are transported to the next production line by mechanical arms and conveyor belts. After the electric linear actuators have been finished, the final stage of the assembly is more hands-on. This is done by professionally trained assembly workers following a manufacturing document created by engineers to assemble the final pieces. Quality assurance experts monitor each step carefully, examining the components finished before going to the next step.

Quality Control

After the complete assembly of the actuators, they are sent to the Quality control team to be inspected for the first article. The first article inspection verifies the dimension’s accuracy, making sure that every parameter is met. Stress testing is done by the first article unit, to ensure that they meet the IP rating, operating temperature, and duty cycle requirements.

After the satisfaction of the Quality control team by the results, then the whole batch is approved to be shipped out to the distribution center. Once arriving at the distribution center, the products are received into a warehouse. The units are then inspected again by the product engineer for a few minutes to ensure that the products meet all the specification requirements and are not damaged as they were being transported.

The products are then added into the stock units and ready for purchase. After purchasing some products, the logistics team tests the units again before they carefully pack them and prepare them for shipping.

The Components of an Electric Actuator

The various components of an electric actuator will be discussed in this section.

Front/Rear Clevis

This is a metal piece that is u shaped, with holes in each end through which a pin, bolt, or fastening device is run. The actuator is allowed to be mounted to the application by clevis attachments on the front and rear.

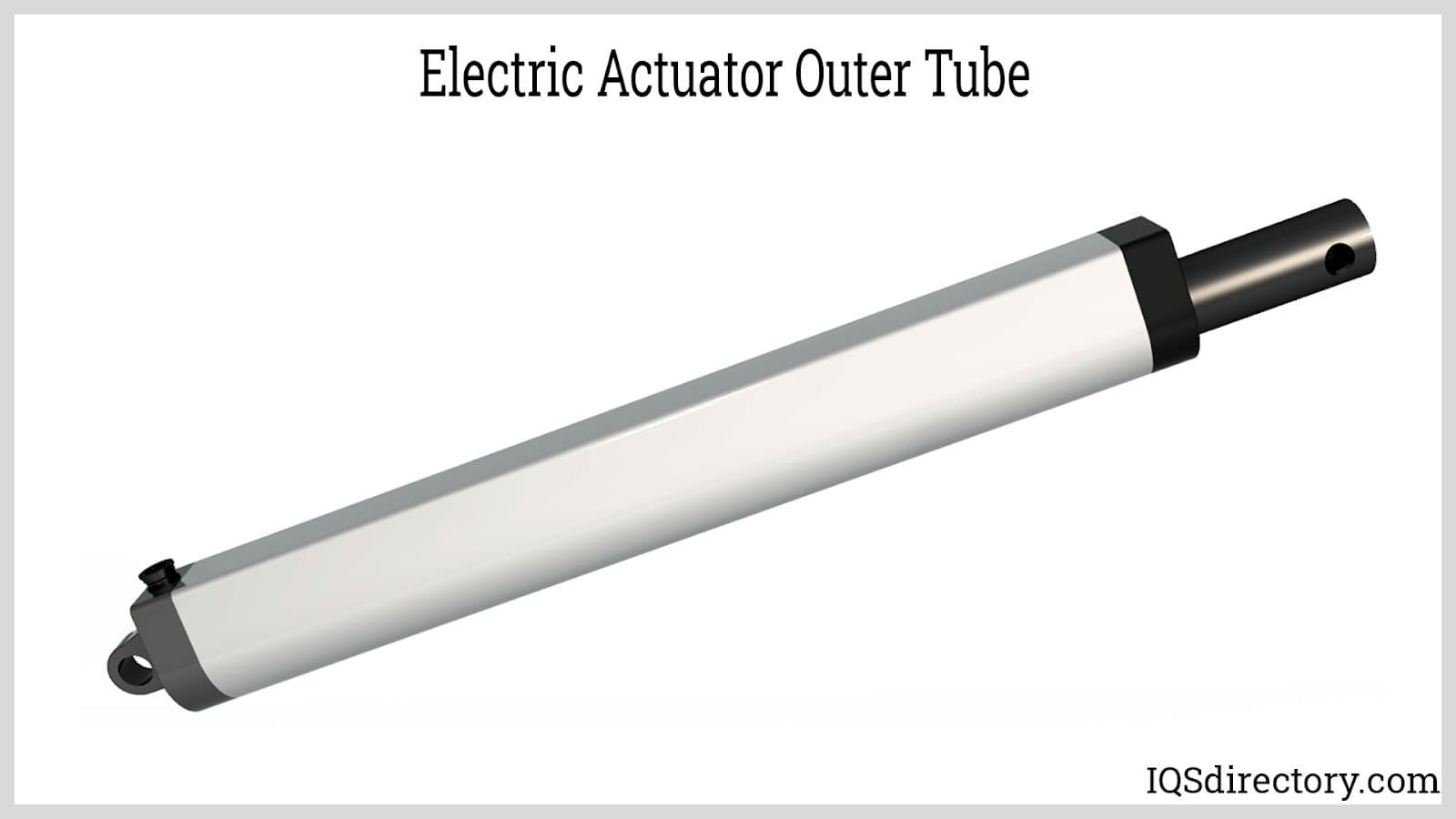

Outer Tube

This is also called the cover tube. It’s an extruded aluminum tube that protects the linear actuators outside and houses all of the inner components of the actuator.

Inner Tube

This is also called the extension tube, translation tube, piston, or drive tube. The inner tube is usually made from aluminum or stainless steel. The inner tube is where the spindle is located, while retracted. This tube is attached to the drive nut that is threaded and extends and retracts when the nut’s motion along the rotating spindle.

Spindle Component

This is also called the rotating screw, lead screw, or lifting screw. It is a long rod that is straight that turns in a tool or machine. This segment of the linear actuator rotates, retracting or extending the inner tube, which generates linear motion. The steel spindle ensures strength and durability. There are different ways of threading the spindle for various speed and load capabilities.

Safety Stop

This is located at the end of the spindle. It serves to prevent the inner tube’s overextension.

Wiper Sealing Component

This is a sealing component that is attached to the end of the outer tube. It prevents contaminants such as dust and liquids from entering the spindle area of the actuator. It also ensures that there is a proper seal between the inner and outer tubes, influencing the IP rating of the actuator.

Drive Nut

This travels along the spindle and is attached to the inner tube. It is the component that permits retraction or extension of the inner tube. The drive nut can be made from plastic or metal and is keyed sometimes to prevent inner tube rotation.

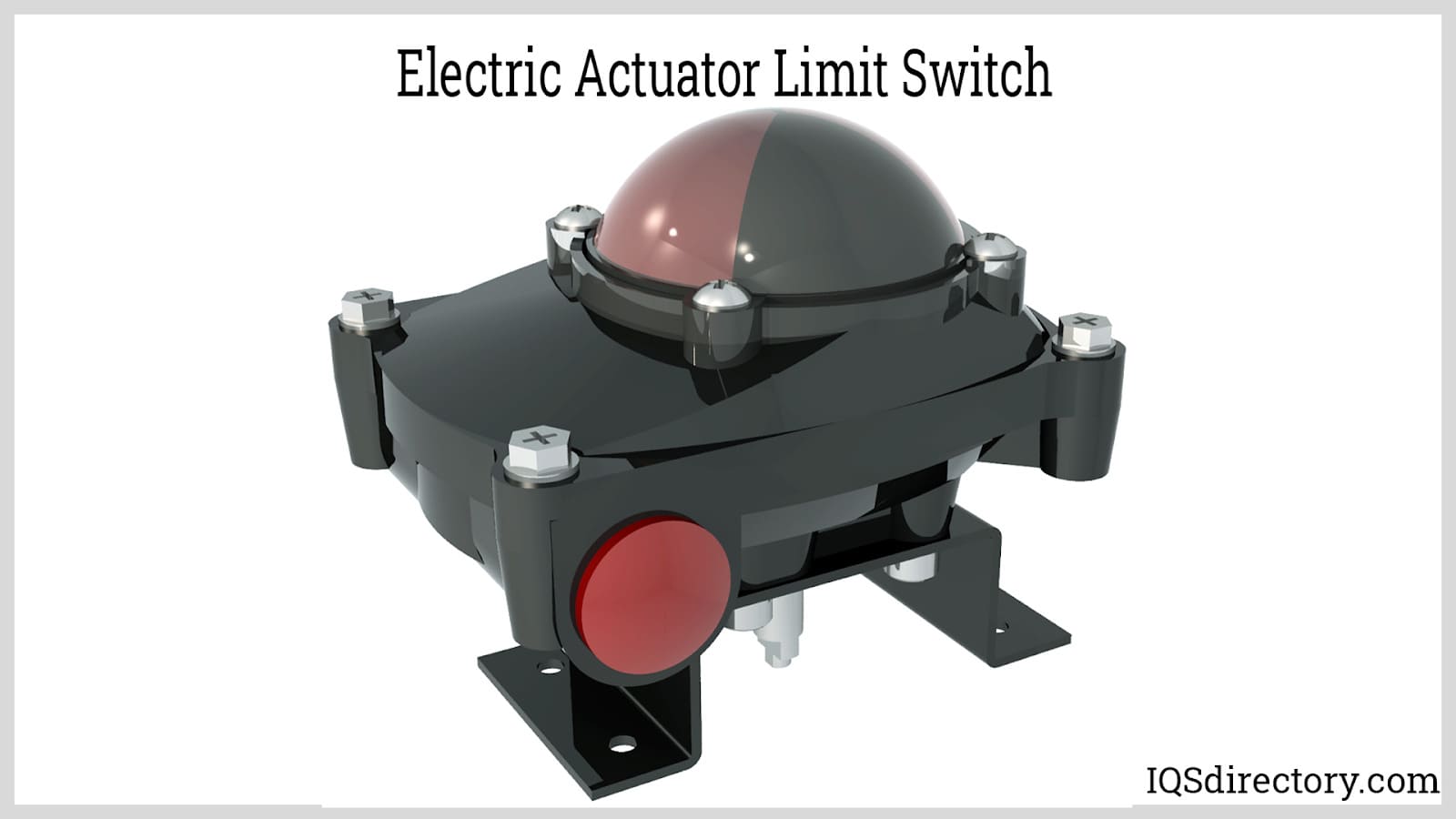

Limit Switches

These control the position of the fully extended and retracted inner tube by cutting current electrically to the motor. These switches do not allow the actuator to overextend or over retract. To add on top of cutting current, limit switches are also able to be used as signal sending devices.

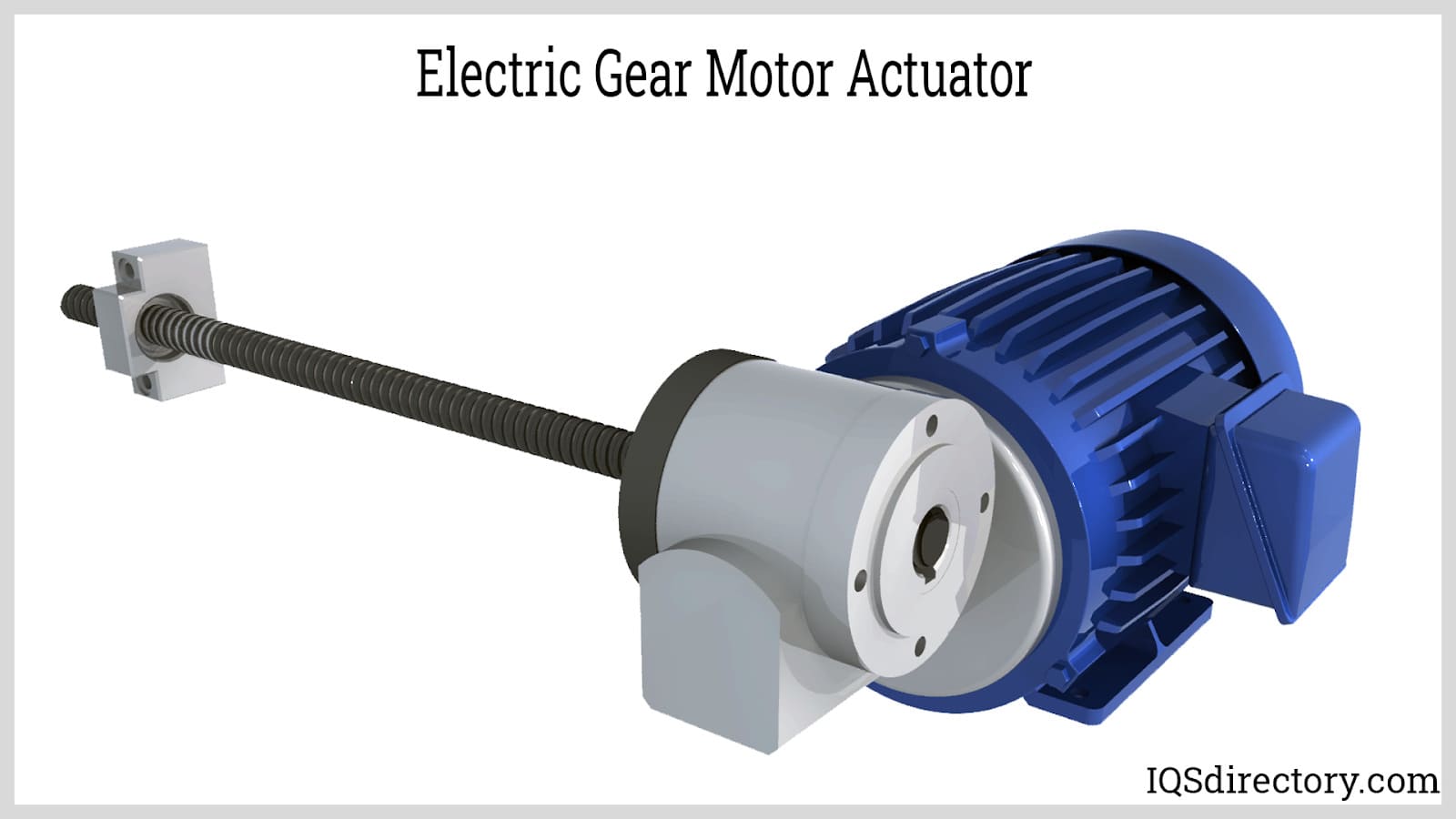

Gears for Electric Actuators

These are made from plastic or steel and mate with other gears to alter the relationship between a driving mechanism’s speed and the driven part’s speed. The gear that is connected to a power source like the motor is known as the drive gear.

Motor Housing

This housing contains the gear motor as well as all internal parts without leaving anything exposed to damage from the external. Motor housing is typically made from high-quality plastic.

DC Motor

The direct current motor is where all of the electric actuator’s power comes from. DC motors are found in different types. There are the most commonly used motors called brushed motors. The motors consist of the following components:

Motor Stator

This is the stationary outside portion of the motor. It consists of the housing of the motor, motor caps, and two permanent magnets. A stationary magnetic field is generated by the stator and it surrounds the rotor.

Rotor

This is also called the armature. It is the motor’s inner part that rotates. It consists of a motor shaft, silicon steel laminate, copper windings, and commutator.

DC Motor Commutator

These are a pair of plates that are attached to the shaft of the motor. They bring two connections for the coil of the electromagnet. The commutator functions to reverse the polarity of the motor and essentially keeps the motor in rotary motion without losing torque.

Carbon Brushes

These make use of sliding friction for the transmission of electrical current from the stator to the motor’s rotor.

Motor Shaft

This part serves for the connection of the gear motor to the bottom of the stator on the DC motor.

Output/Feedback Sensors

These are used for the communication of the actuator’s stroke position. The feedback given by these components is sent to the control box MCU. Linear actuators that contain position feedback are typically required when an application includes high level functions like synchronization and memory positioning. There are multiple options of output sensor including:

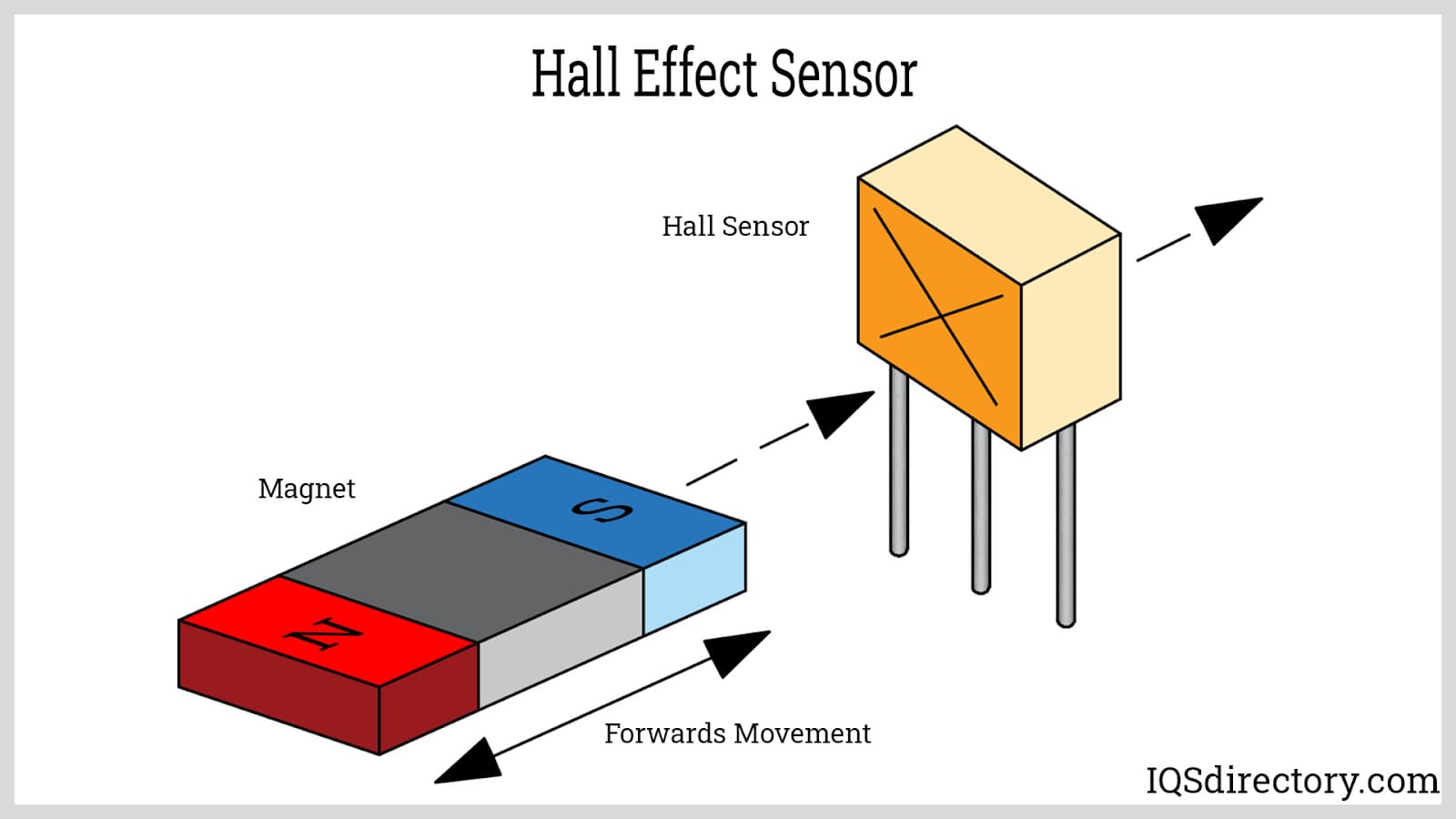

Hall Effect Sensor

The output signal from this type of sensor is the magnetic field density function, around the device. When the magnetic flux density of the sensor goes beyond a certain pre-set threshold, the sensor detects it and creates a hall voltage which is an output voltage. A linear actuator having position feedback is important due to its accuracy and reliability, exactly what the hall sensor provides.

Potentiometer (POT) Sensor

This type of sensor consists of a wiper and two end connections for changing an electrical signal output. During the turning of the linear actuator lead screw, the resistance between the wiper and the two end connections changes also. Each value of the resistance corresponds to a position in the actuator’s stroke.

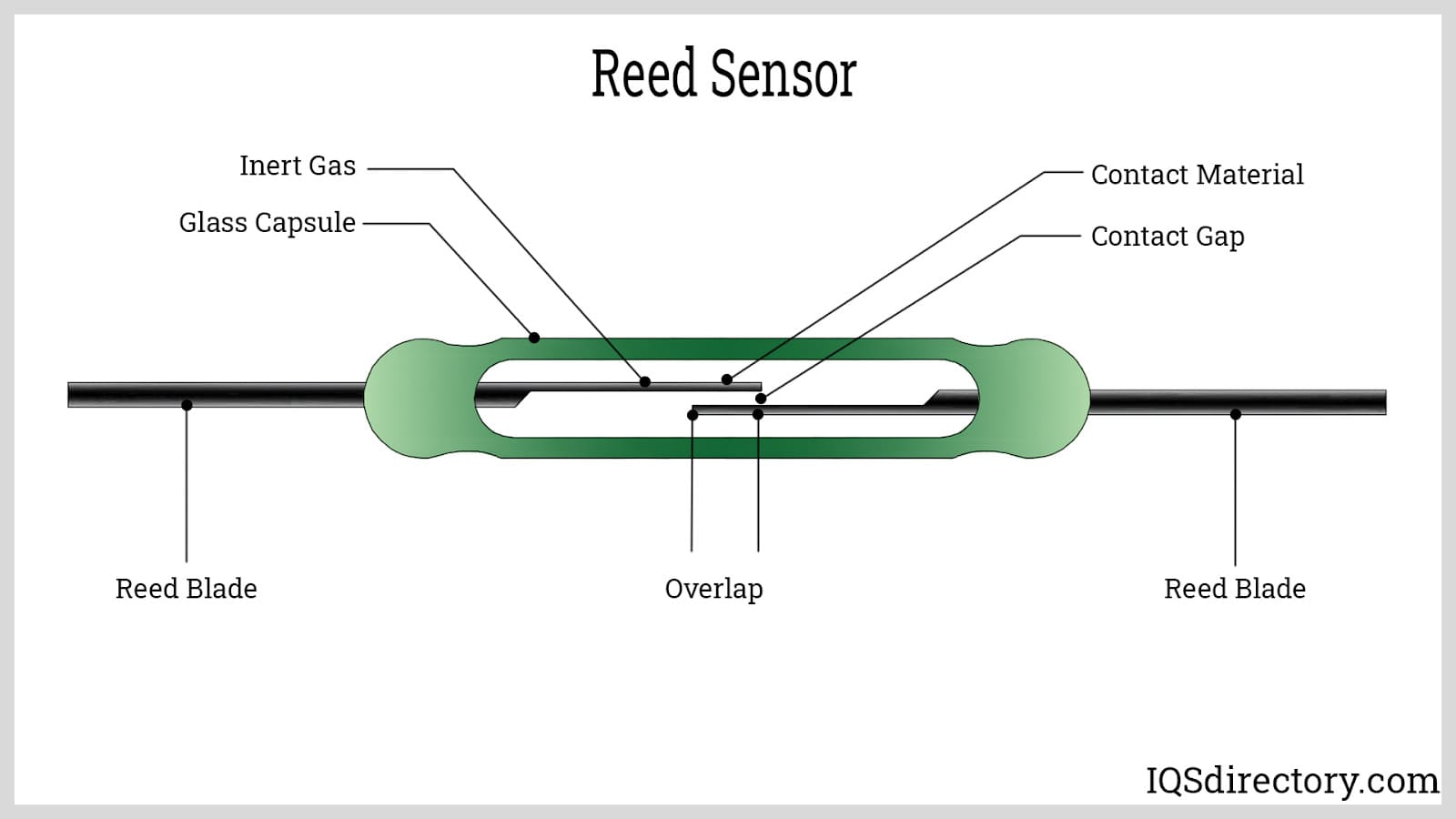

Reed Sensor

This type of sensor is a magnetic positional sensor. It is an electrical switch and operated by a magnetic field that is applied. It consists of a pair of contacts on reeds made from ferrous metal in a glass envelope that is sealed. The contacts may be open normally but close during the presence of a magnetic field (closing the circuit as well as cutting the power of the actuator).

How an Electric Actuator Functions

The electric motor creates a rotary motion during the rotation of the spindle or rotor. The motor spindle rotates in a ball screw nut. This motor spindle is coupled directly to a helical screw via the shaft of the drive.

The ball screw nut is driven forward or backward during the rotation of the spindle, along the helical screw. There is an attachment of a hollow piston rod to the ball screw nut and this generates the linear motion into, or out of the linear actuator during the clockwise or anti-clockwise rotary motion of the motor.

An electric drive controls the motor, and allows the varying of the speed of rotation, and hence the actuator’s linear speed. A mechanism for feedback provides positional information and the linear actuator is capable of being programmed to move a certain position, stop the position and then move on again, or return to its position of rest.

The torque that can be generated is determined by the power of the motor. Hence the power will also determine the force that can be put to useful motion through the actuator.

Chapter 2: Types of Electric Actuators

The various types of electric actuators include:

Smart Linear Electric Actuator

This is a smart linear actuator with the dislocation of linear output. This actuator has a high quality, stable precision material and design, is durable and safe, has a broad application environment, similar to all types of valve, ball valves such as control and butterfly.

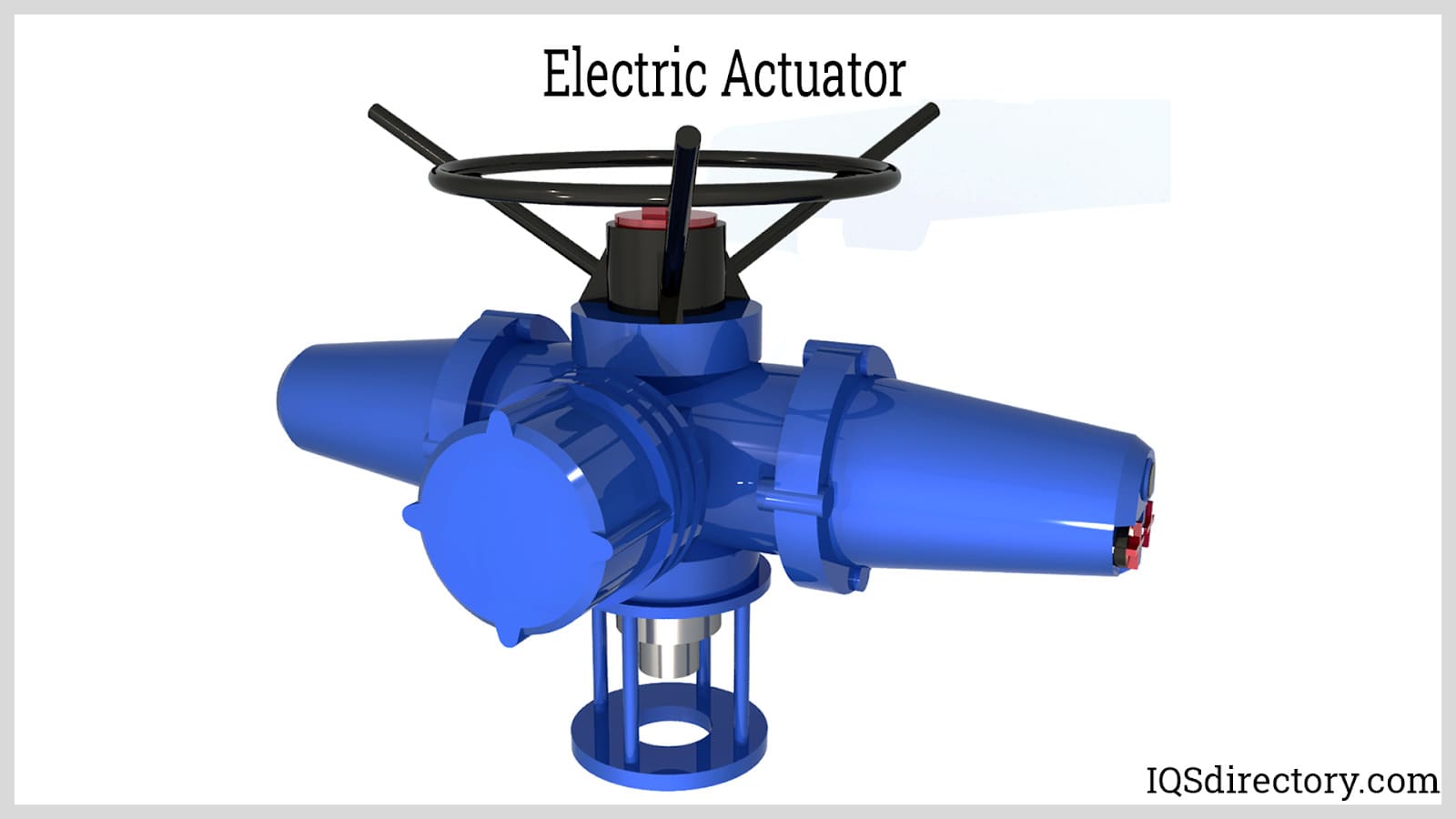

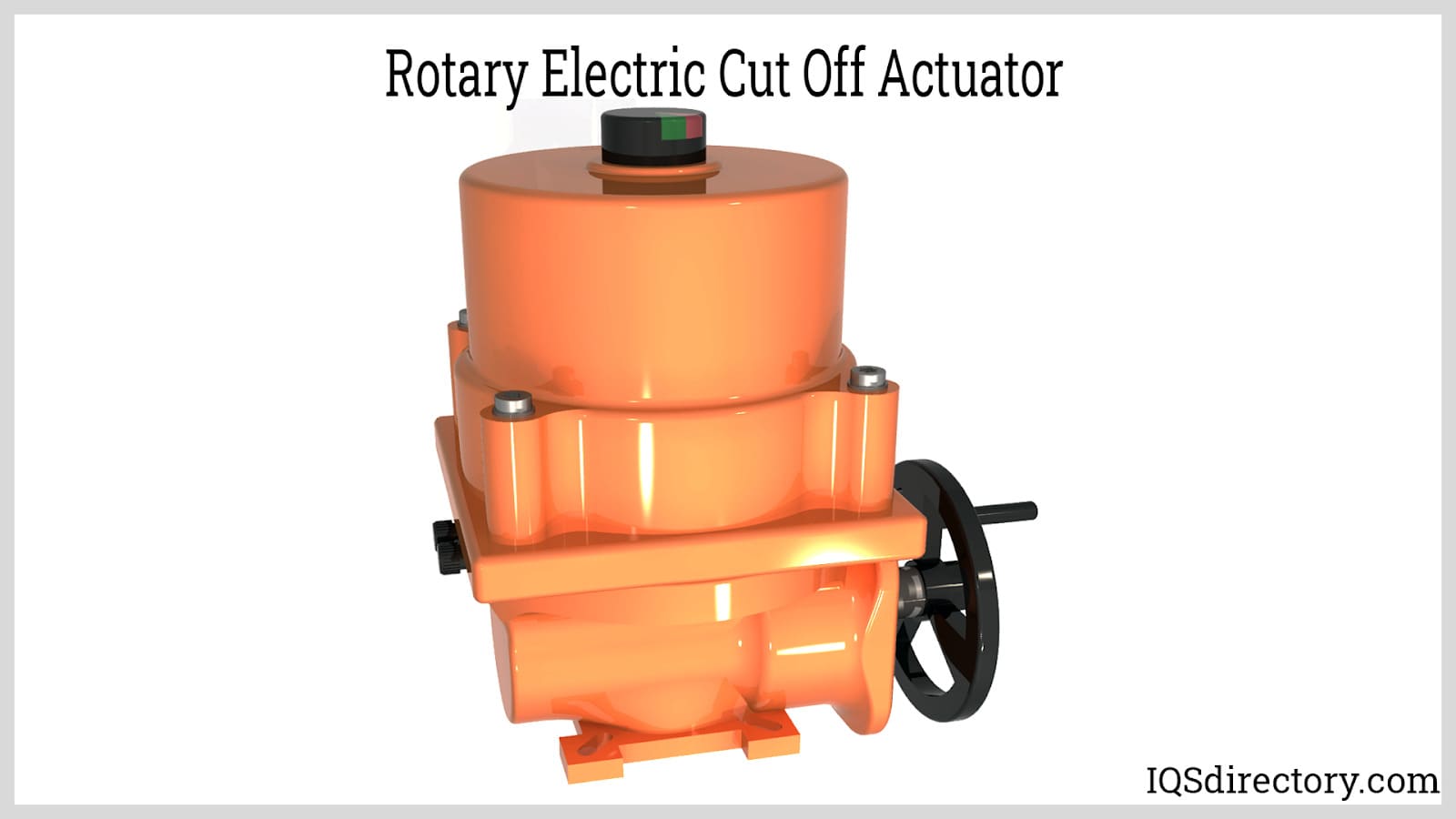

Rotary Electric Cut Off Actuator

These types of actuators allow the integrated standard signal. They alter the signals into an angular displacement that are equivalent so as to control the valve mechanically and achieve the automatic modification task.

In the automatic change, the mechanical, physical and bi-directional intrusion free control of the system responsible for regulation can be recognized. It consists of two parts which are the actuator and servo amplifier. At a distance, it can be controlled physically or rapidly.

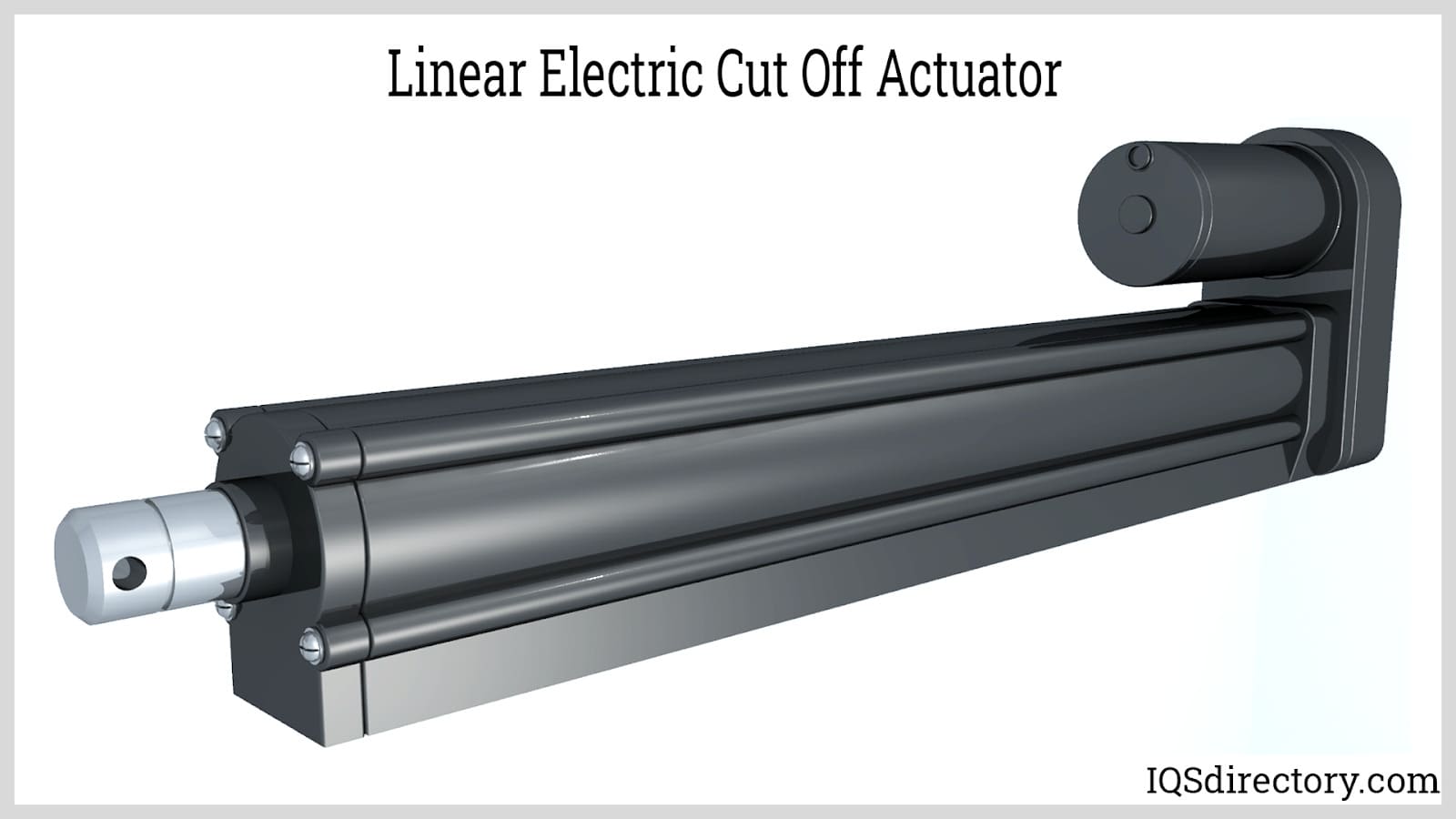

Linear Electric Cut Off Actuator

This type of electric actuator is available with two sorts of power supply models like AC single-phase power supply and AC three-phase power supply. To attain a prearranged linear reciprocating motion, the latest electric actuator is established from the regulator control signal.

This electric actuator sequence is employed as the regulating valve actuator. The control valve itself needs a change function that varies, and the opening of the valve signal function of the electric actuator and physical function. Hence it finds its extensive use in industries such as metallurgical, power generation, papermaking, environmental protection, petrochemical, and light industries.

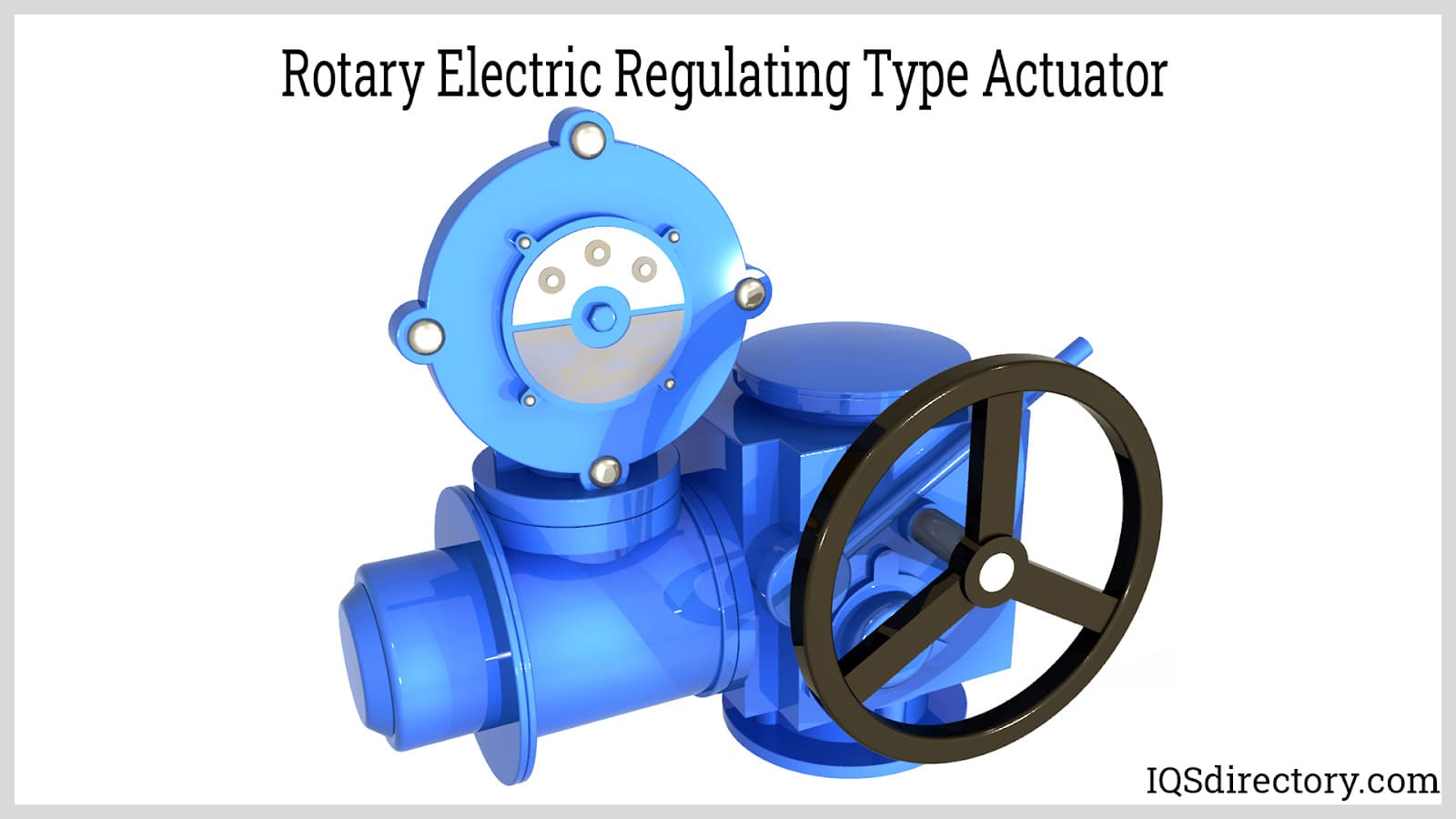

Rotary Electric Regulating Type Actuator

This is a full electronic actuator type that gets 4mA – 20mA or 1V – 5V dc input signals from the operator, PC, or regulator to work with a single phase AC power supply of 220V like the power supply of the driving, and is available with a servo system. There is no necessity for an extra servo amplifier. The controller of the input component accepts the integrated circuits that are complex and mixed, and is hardened by resin pouring and topic to aging behavior.

Thus being high inconsistency and opposing moisture and vibration. When there is an acceptance of the base and crank for fitting, the determination of the location of the crank zero ends can be done randomly within 0 to 360 degrees Celsius. To add on top, the electrical actuator has the temperature, overload, and torque switch safeties. It is a product of high inconsistency, high in control precision, and with a variety of changeable mechanisms for angular travel, it is competent in figuring out the angular travel electric regulating valve.

SMC Electric Actuator

These types of electric actuators provide different advantages; acceleration and speed are controlled and can also be predicted. There can be an achievement of several positions with high accuracy and repeatability. Forces can be almost automatic. With no requirement for condensed air, there are fewer energy costs as well as infrastructure. These types of actuators are designed with a center on easy process and arrangement.

The function parameters are fixed. In addition, there is an easy mode that lets you operate rapidly. The following are the different types of SMC electric actuators: sliders, AC servo sliders, rod and guided rod, AC servo rod, slide tables, rotary, grippers, miniature, controllers, and drivers.

Comparison of Electric Actuators and Counterparts

This section will compare and contrast electric actuators to their counterparts.

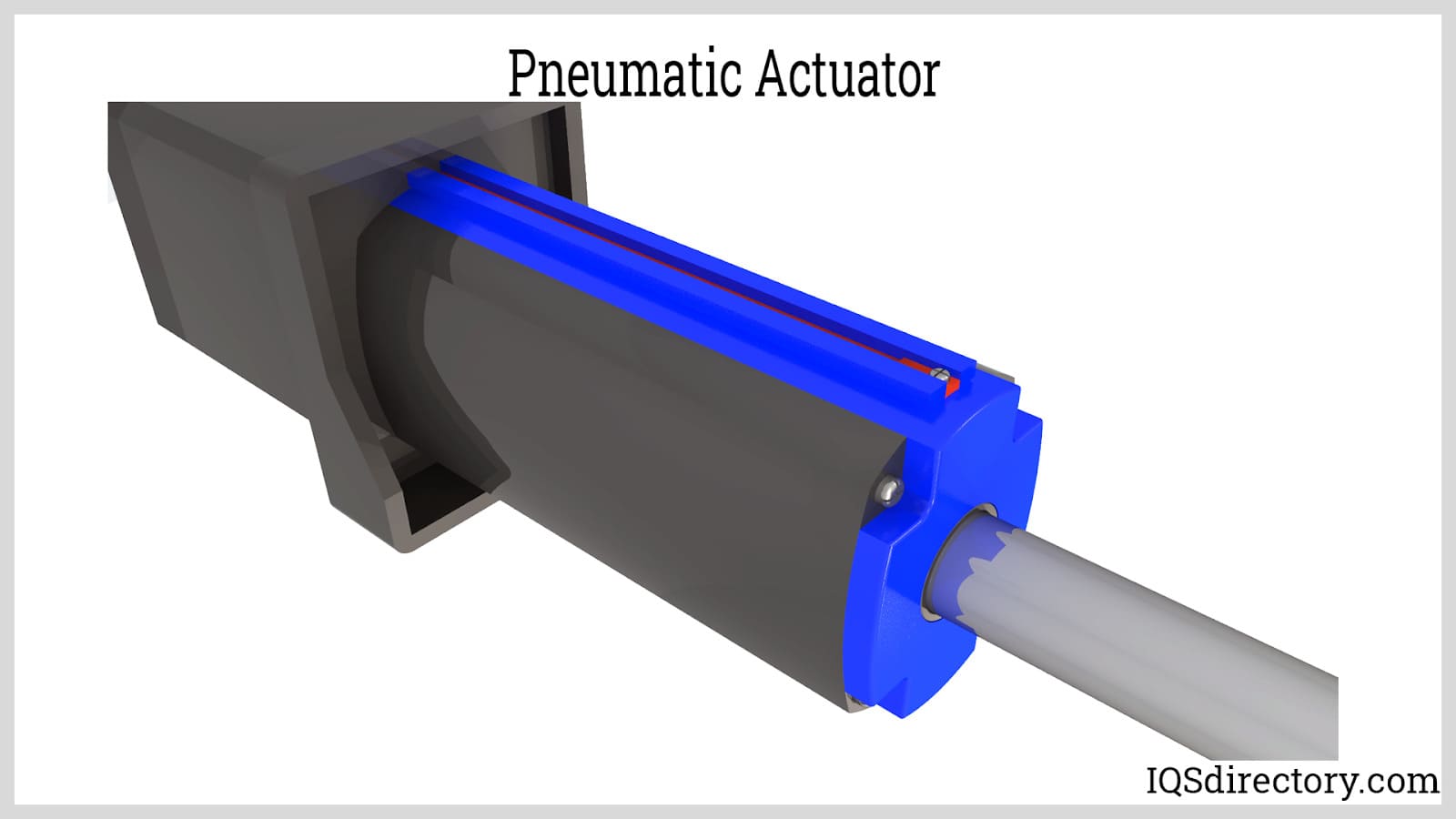

Electric vs. Pneumatic Actuators

Comparing electric actuators vs pneumatic actuators shows that:

Power Source

The diving force of these actuators is the biggest difference between them. Pneumatic actuators need an air supply of 60 – 125 PSI. The solenoid (pilot) valve is controlled by either an AC or DC voltage. When there is no air supply available, electric actuators come into play.

Component Size

The size of double acting actuators is up to 70% smaller as compared to electric actuators.

Actuator Speed

To close or open the valve, pneumatic actuators take half a second to one full second, depending on the model. Electric actuators, on the other hand, take approximately six seconds or above.

Pneumatic and Electric Temperature

Pneumatic actuators suit a wide variety of ambient temperatures, and their rated temperature range is -20 degrees Fahrenheit and 350 degrees Fahrenheit. Electric actuators are susceptible to overheating in applications that involve high temperatures and are often rated between 40 degrees Fahrenheit and 150 degrees Fahrenheit. However, the temperature restrictions vary according to the product and the guidelines of the company for rating their products.

Durability and Longevity

The cycle of high quality rack and pinion style pneumatic actuators is up to 1,000,000 +/- times when they are used within the specifications. The cycle of electric actuators is 250,000 +/- but they depend on the application.

Spring Return

The spring-return or failsafe option is a safety feature for valve actuators. In the case that there is power or signal failure, the valve is set to the safe position by the spring-return, determined by the operator. For pneumatic actuators, there is a wide availability of spring-return failsafe options. With electric actuators, this feature is not as easily implemented.

Cost of Electric and Pneumatic

Electric ball valves generally cost more than pneumatic ball valves. When used within specifications, pneumatic ball valves have a lifespan that is long and may deliver the best overall value according to your application.

Electric vs. Hydraulic Actuators

Comparing electric actuators vs hydraulic actuators shows that:

Hydraulic Force

Force = pressure x area in hydraulic cylinder systems. So even a cylinder that is 3 inches can achieve 15,000 lbf (66,723.3kN) at 2200 psi. Hydraulic cylinders are however oversized more often so an application’s actual force requirements may be obscured. To achieve force in a hydraulic actuator, it must wait for the building up of pressure.

Electric actuators make use of the current passing through the servo motor to produce torque for the driving of the power screw and generate force. Multiple electric force linear actuators make use of roller screws which have excellent force transmission capabilities. With an electric linear actuator, the force is instantaneous.

Providing Control

In simple end to end position applications, a hydraulic actuator works well. However, motion profiles that are complex may need expensive servo hydraulic systems. An electric actuator with a servo motor provides control that is infinitely over position, acceleration or deceleration, velocity, output force and more. On the fly, it is possible to make adjustments. The levels of accuracy and repeatability are far better than those of a hydraulic system.

Hydraulic and Electric Velocity

It can be difficult to deliver high force for both hydraulic and electric actuators. For a hydraulic cylinder, for the achievement of high speeds at higher forces there must be sufficient pressurized oil in the system for pushing the oil in the cylinder in the time that is required. There may be a need for an accumulation system to hold the pressurized volume.

An electric actuation system is dependent on the motor RPM, torque, and the characteristics of the screw to deliver high force. But there is a limit in speed due to the decrease in RPM that occurs as the torque increases when the servo gets larger. On the positive side, the electric actuator doesn’t have to stroke each cycle’s whole length because of the control that it has over the entire motion profile. The actuator may be capable of delivering peak velocities since it is able to execute shorter, more intelligent moves.

Overall Footprint

The footprint of a hydraulic cylinder is compact at the work point, but the hydraulic power unit, which serves in the regulation of oil pressure and flow, needs a lot of floor space. To add on top, additional components like gauges, heat exchangers, accumulators, and cables may be needed. An electric actuator has an overall small footprint with its combination of actuator, drive, motor, cables, and cabinet. In an electric servo mechanism, only a fraction of the space required for a hydraulic cylinder with HPU is taken.

Temperature Sensitivity

Hydraulic systems are very sensitive to temperature. In the cold, the oil gets thicker and slower moving causing sluggish and inconsistent performance. The oil may be degraded or the seals ruined by high temperatures from overheating or the environment. To maintain operating temperature in the cold, an added tank heater is utilized, while overheating is mitigated by a heat exchanger.

The system costs are increased by the addition of either piece of equipment. Electric actuation systems are less sensitive to temperature since they can be chosen to run at a designated temperature for the given amount of work required. For fast response in the cold, electric actuators can be specified with extreme temperature grease.

Life and Maintenance

Hydraulic cylinders are rugged devices that provide long life service when they are properly maintained. However, maintenance needs staff time, new seals, oils and filters, and machine downtime. If there is a correct sizing of the electric linear actuator for the application, there is no downtime because there is no maintenance required. The selection of a proper electric rod begins with an accurate calculation of actuator life.

Data Collection

Basic hydraulic actuation systems don’t have capabilities for data collection and reporting. Only expensive, complex servo-hydraulic systems can track and monitor position, force, velocity, etc. at the work point. The capability of sensing is built into an electric actuator’s servo system. The monitoring of motor current tracks force and repeatability. The motor’s feedback registers the position and velocity and the reporting is done through the PLC and the drive.

Electricity Costs

Typically, hydraulic systems are 40 to 50% efficient in converting electrical energy to motion. Electric linear actuators typically operate in the 75 to 80 % efficiency range.

Environmental Impact

Hydraulic actuation systems leak. Leaks create contaminant products, safety hazards, and pollute the environment. The clean-up is costly. Electric actuation is one of the cleanest technologies compared to its counterparts. The only potential contaminant is grease on the roller screw, and special greases can be specified.

Leading Manufacturers and Suppliers

GET YOUR COMPANY LISTED ABOVE

Chapter 3: Applications & Benefits of Electric Actuators

This chapter will discuss the applications and benefits of electric actuators.

Applications of Electric Actuators

The applications of electric actuators include:

- Electric actuators are utilized in driverless transport vehicles in the automotive industry. They are also used in the automotive industry for the selection of jointing methods and dispensing-welding, gluing, and riveting.

- Electric actuators are utilized in the food and beverage industry, for making PET bottles, filling, and labeling systems. They are also used in robotic applications like milking robots.

- Electric actuators are utilized in materials handling for operations like servo presses and clamping and most commonly used in the packaging sector.

- Electric actuators are used in electronics and electronic assembly, robotics, machine tools and multiple industrial sectors.

- In upstream, midstream as well as downstream oil and gas plants, electric actuators are used.

- Electric actuators are used in pulp and paper plants.

Benefits of Electric Actuators

The benefits of electric actuators include:

Easy Integration

Electric actuators are much easier to integrate than hydraulic or pneumatic actuators. Electric actuators come with programmable controllers and microprocessors for the management of the operation of most modern industrial machinery.

Precision Levels

Electric actuators offer high levels of precision in the control of motion. This is due to the enabling of the torque, speed, and force that they do to modify at different stages during motion.

Safety and Convenience

These types of actuators are not susceptible to contamination or leakages like their counterparts. Therefore they are considered to be cleaner, safer, and more convenient options.

Costs Less

These types of actuators are more economical in the long run than other actuators. Electric actuators need less maintenance, are easy to operate and install and are rugged. They also last longer and are reliable when used in different environmental conditions.

Other benefits of electric actuators are listed below:

- They can be easily assembled because of their simple quick connect wires and cables.

- Electric actuators are more compact with smaller footprints and they don’t make any annoying noise during their operation.

- Setting the acceleration and deceleration is easy

- No external sensor

- Electric actuators help in the adaptation of machines to flexible processes.

Drawbacks of Electric Actuators

Some of the drawbacks of electric actuators include:

- Higher initial equipment cost

- Non-explosion proof

- They are sensitive to vibrations

- The higher the thrust, the less the speed

- The high the speed, the less the thrust

- More complex technology

However, the benefits of electric actuators outweigh the electric actuator drawbacks.

How to Select an Electric Actuator

The electric actuator is required for an application that requires force. In the case of a pneumatic linear actuator, the force is generated by pressure acting on the piston’s surface area. In the case of electric actuators, the force is generated from the torque capability of the motor. The load that must be moved, any surface frictional forces and the elevation angle, or declination, of the load are critical parameters that must be taken into consideration.

In the case of pneumatic actuators, there is a certain distance that must be moved by the load that determines the actuator’s stroke. The same goes for an electric actuator also but with some subtle differences. To protect against over-run, the maximum stroke is the usable stroke, but less than four times the helical screws pitch. A number of positions are possible for use of an electric actuator; therefore the total movement must be taken account of by the required stroke. There are different screw pitches available depending on the bore, permitting combinations of components to meet many application requirements.

Another consideration that must be made is when an electric actuator is preferable to a pneumatic solution. If there is a situation in which there is no compressed air supply, the only alternative is electric, if hydraulic solutions are not available also. Electric actuators have a key advantage of the requirement for multiple positions in an application. Other advantages that must be considered in the selection are low noise, high accuracy, load stiffness, flexibility through control characteristics and overall lower operating costs.

Efficiency and Energy Savings of Electric Actuators

Electric actuators offer control and positioning that is extremely accurate. To add on top, electric actuators help adapt machines to processes that are flexible and have a low operating cost. Therefore the electric system is energy efficient and can provide cost savings in multiple cases.

Electric actuators are the most efficient option in applications where there is a requirement for multiple positioning points. This is because of the fact that pneumatic cylinders require themselves to be coupled with multiple accessories to perform these same types of motion. This will lead to a higher cost and low accuracy and efficiency in the long term use. The ability of electric actuators to start and stop almost immediately as soon as a command is given is another way they beat hydraulic or pneumatic actuators.

In electric actuators, there is no delay and lag. Pneumatic cylinders need your compressor to run constantly for the maintenance of pressure. On the other hand, electric actuators only need to run when there is a requirement of work. This means that electricity costs for your business are saved.

Conclusion

Electric linear actuators are devices that convert electrical energy into motion. There are different types of electrical actuators offering different capabilities. Electric actuators are more advantageous than their counterparts since they can be easily assembled, are more precise and cost less, only to mention a few benefits. They can also be safely used in a wide variety of applications.

Leading Manufacturers and Suppliers

GET YOUR COMPANY LISTED ABOVE

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)