What is Electrical Discharge Machining (EDM)? Plus 3 Types

Since the advent of numerically controlled lathes in the 20th century, traditional machining using cutting tools have played a major role in fabricating different components used in a broad range of industries. But just like in every innovation (or technology), traditional machining methods have reached their limits in recent years and are being replaced by more recent technologies like Electrical Discharge Machining (EDM).

Electrical discharge machining (also called spark machining or spark eroding) eliminates the need for mechanical forces (or tool contact) when removing material from a workpiece. Instead, an EDM uses thermal energy for the removal process, creating the desired parts accurately and precisely.

Do you want to learn about how EDMs work, the different types of EDMs, and the advantages of EDM over traditional machining methods? You’ve come to the right place!

How Does Electrical Discharge Machining Work?

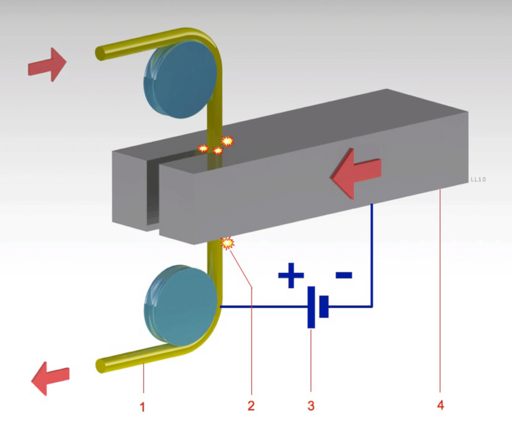

An electrical discharge machine typically features an electrode that helps to disintegrate electrically conductive materials like carbide or hardened steel.

Unlike conventional machining, where a cutting tool is rotated against a workpiece, the EDM electrode doesn’t usually make contact with the workpiece. Instead, it is positioned such that there exists a small gap between it and the workpiece.

To create cuts or fabricate parts, a high-frequency electrical spark is discharged from the electrode to the workpiece. This electric discharge vaporizes (or melts) the surface of the metal, creating desired cuts.

The movement of this electrode around the workpiece to fabricate parts is usually controlled using Computer Numerical Control (CNC) technology. However, the successful operation of EDM goes beyond CNC technology and electrical discharge; the electrode and workpiece are usually submerged in a dielectric fluid, which helps control the sparks and cool the workpiece during machining.

What are the Types of Electrical Discharge Machines?

Electrical discharge machines come in three types:

- Sinker Electrical Discharge Machine

- Wire Electrical Discharge Machine

- Hole Electrical DIscharge Machine

#1 Sinker Electrical Discharge Machining

The sinker EDM, also referred to as ram EDM, is the most commonly used EDM type today. The electrodes used in sinker EDM are pre-machined to form a reverse (or mirror) image of the workpiece. So when you press this electrode onto a workpiece and generate an electric spark, it creates a negative version of the original shape.

Look at it this way. Let’s say you want to fabricate a cuboid cavity on a workpiece using sinker EDM. Then, you must machine the electrode to have a cuboid protrusion to get your desired shape, as shown in the figure below.

Sinker EDM is ideal in applications with stringent surface finish requirements, especially when cutting exotic or tough materials. It allows you to cut materials without worrying about polishing the workpiece after the machining process. However, a major drawback of sinker EDM is its slower material removal rate compared to other EDM types.

#2 Wire Electrical Discharge Machining

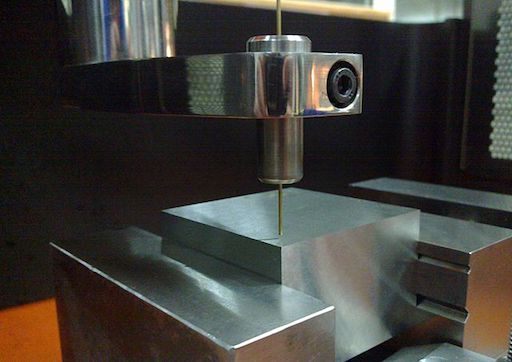

Wire EDM, also called wire erosion, features a thin wire (usually made of brass or copper) that works as the electrode. Its operation is quite similar to conventional CNC machining since this wire moves through the workpiece, vaporizing metal surfaces within its vicinity and creating cuts to form the desired geometry.

However, unlike in conventional machining, the wire electrode must pass through the metal workpiece completely before you can create cuts using this manufacturing process. What this simply means is that wire EDM creates 2-D cuts in 3-D parts.

Wire EDM is ideal if you’re looking to cut small pieces of materials accurately. It is also the go-to EDM method for prototype manufacturing because of its low cost and high precision.

Learn more about the difference between accuracy and precision.

#3 Hole Drilling Electrical Discharge Machining

As the name suggests, the hole drilling EDM process is used to drill holes. A hole electrical discharge machine features a tubular electrode with dielectric fluid (such as deionized water) flowing through it, allowing it to achieve faster hole drilling than conventional drilling machines.

It is especially useful for machining extremely small holes, eliminating the need for deburring.

Choosing Between CNC Machining and Electrical Discharge Machining

As we always tell our customers, CNC machining and EDM are advanced machining technologies capable of creating pretty much any product design.

However, while you might be able to create any design using these two technologies, a wrong choice might lead to greater lead times and slight inaccuracies. EDM is especially useful for machining tough, conductive materials like titanium and tungsten. You should also opt for EDM if there are concerns about a material’s fragility since EDM eliminates the need for high cutting force to remove material.

Gensun Precision Machining is a leading provider of CNC machining and EDM services across Asia. We have a team of highly experienced machinists and engineers who can help determine which method is ideal for your manufacturing project.

Reach out and tell us more about your project today.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)