Machining 101: What is Electrical Discharge Machining?

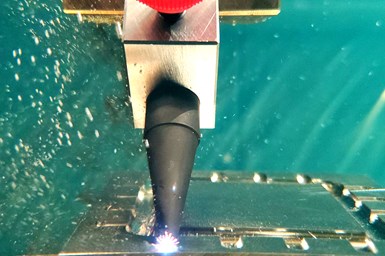

The visually impressive sinker EDM process actually only works one spark at a time. But with anywhere between 500 and 30,000 sparks every second, human eyes cannot keep up with it — and neither can most cameras.

Photo Credit: Adam Wysuph, MC Machinery

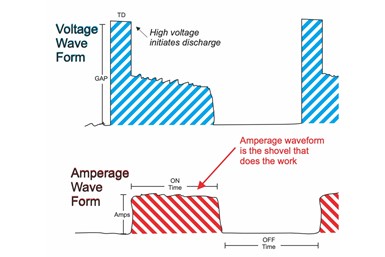

Electrical discharge machining, or EDM, is a non-contact process that can machine parts regardless of their hardness. It involves placing an electrode or wire and an electrically conductive workpiece into a circulating dielectric fluid. The fluid acts as an insulator until a specific spark gap and voltage ionizes it and enables a spark to travel to the workpiece. This spark has a temperature between 14,430 and 21,630° F (8,000 – 12,000° C), high enough to erode part of the workpiece. Using a CNC, the operator moves the electrode or wire as needed and rapidly turns the current on and off. This accommodates the flushing of molten material (often called “swarf”) from the workpiece. The relationship between on-time and off-time is called the EDM process’ “duty cycle.”

There are two main variations on the EDM process: sinker (also called “ram” or “vertical”) EDM and wire EDM. Each uses different materials and is suited to different final applications.

Mục Lục

What is Sinker EDM?

Sinker EDM uses an electrode as its “cutting” tool, with the shape of the electrode serving as a mirrored, slightly smaller image of the finished form it will produce in the workpiece. The electrode makes one spark at a time — but the frequency of the current means the tool could produce anywhere between 500 and 30,000 sparks per second.

Electrodes for sinker EDM are typically either copper or graphite. A copper electrode works well for small parts and parts that require fine surface finishes, but its thermal expansion characteristics make it unsuitable for larger parts. Additionally, these electrodes are toxic to living tissue and can contaminate the dielectric fluid, causing oxidation of the workpiece. Nonetheless, copper electrodes often see use when working with low-melting-temperature alloys like aluminum, brass and copper, as well as with carbon and stainless steel. Many operators combine the copper with up to 70% tungsten to improve the durability of the electrode, but machining these alloys can require carbide tooling.

Graphite electrodes are copper’s more-common brother, and this type of electrode shows high heat resistance, excellent electrical conductivity, good thermal expansion characteristics and good machinability — but can achieve only mediocre surface finish. In general, graphite electrodes are best for large parts or high-volume work that does not require a smooth finish or fine details.

Changing voltage parameters should change amperages, and therefore the spark parameters in the EDM process.

Photo Credit: Pat Crownhart, MC Machinery

No matter which material the operation uses, thermal damage afflicts electrodes in sinker EDM. Factors impacting wear include spark frequency, polarity and amperage. Leaving a current on for longer periods makes a low-frequency operation, sacrificing surface finish to increase material removal rates. The inverse is also true, with high-frequency operations increasing surface finish. Graphite electrodes exhibit greatly increased wear in high-frequency operations.

Positive polarity protects the electrode from wear and better guarantees dimensional accuracy, but negative polarity increases wear to boost material removal rates by as much as 50% in graphite electrodes. Copper electrodes also see some of these effects, but they are not as pronounced.

Recommended amperages for sinker EDM are from 50 to 65 amps per square inch of the electrode’s surface contacting the workpiece. Copper electrodes can use up to 100 amps total, while graphite electrodes can accept up to 600. Higher amperages support roughing operations, while lower amperages are necessary for finishing or fine-detail operations.

Sinker EDM’s primary application is the machining of molds, but it can also be used for tapping in hardened materials and in tough aerospace alloys, as well as for other tasks.

What is Wire EDM?

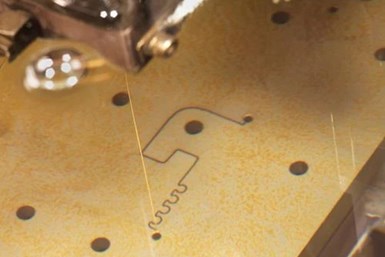

Wire EDM feeds a strand of wire from a supply spool to the workpiece via a wire drive system. The wire is energized by electrical contacts and passes through the workpiece at a specific velocity determined by the operation at hand. A stream or bath of deionized water surrounds the wire, and sparks are continuously emitted along the length of the wire. Rollers pinch the wire and provide tension, while guides above and below the workpiece position the wire on its path — helping it to achieve complex shapes on the workpiece.

The wires used in this process commonly have diameters of 0.010 to 0.012 inch, with finer wires at 0.001 to 0.004 inch. The material of the wires also holds great influence over the operation’s success, as hard wires that have insufficient tensile strength for an operation are liable to break under sudden shock. Softer wires prove more desirable for high-taper cutting operations.

Wire EDM uses a small-diameter wire that emits sparks to machine complex paths. The material of the wire determines its tensile strength and conductivity properties.

Photo Credit: Makino

Combinations of copper, zinc and brass in different core and coating arrangements make up a large variety of wire types used in wire EDM, but there are additional types that work well for particular applications. In particular, molybdenum is good for cutting intricate workpieces with small internal radii (but its cost and poor flushability limit its overall use); steel-clad wire that uses a steel core, coating of copper and final coating of brass is good for extreme cutting operations like machining tall workpieces or parts with extreme flushing limitations; and diffusion-annealed wires are suitable for precision and high-speed cutting (but show limited suitability for automatic threading). Silver-coated brass wires are particularly well-known for their price-to-performance value, and improve the transfer of electrical energy from carbide power contacts to the wire.

Flushing the Swarf

As mentioned earlier, EDM requires a dielectric fluid that acts as an insulator and a conductor with equal success. It must cool both the workpiece and the electrode, and it must flush melted particles away from the spark gap (typically between 0.0005 and 0.005 inch).

In sinker EDM, this is usually a paraffin or naptha-based mineral oil with a high flash point and a low viscosity. With proper filtration and circulation, the oil can last between 18 and 36 months of regular use before replacement.

Sinker EDM generally sees four types of flushing. “Normal flow” flushing, the most common type, is the direction of pressurized fluid through passages in the electrode or the workpiece into the spark gap. “Vacuum or suction” flushing is increasingly popular, and has dielectric fluid enter the electrode at the cutting end and exit through either the spindle end or a hole in the workpiece. “Jet or side” flushing is a compromised version of flushing that uses an aimed spray or jet of fluid from one side of the workpiece — this is used only when the shape and size of the electrode or workpiece will not permit one of the former two methods. “Immersion” flushing provides cooling and particle removal sufficient when the cut is very shallow or passing through a very thin section; its effectiveness improves when the electrode or workpiece can be axially pulsed into or out of the cut to pump fresh fluid into the cutting area.

Wire EDM concentrates deionized water (wire EDM’s dielectric fluid) along the section of the wire that is in contact with the workpiece. This occasionally uses pressurized jets, but more commonly uses “pressure flush cups” with the wire and the dielectric fluid exiting from a nozzle at the bottom. This nozzle should be located close to the part for maximum effectiveness, with a maximum distance of 0.005 inch.

Filtration is important, but wire EDM still causes electrolysis with normal operations. When the electrical current interacts with material contaminated by the chemical changes of electrolysis, surface degradation begins and the depth of the heat-affected layer increases. Anti-electrolysis power supplies can minimize this problem by using voltage modulation in combination with transistorized pulse circuitry and sensors to reduce stray sparks.

Motors Fast as a Bullet Train

In the early rise of EDM, ballscrews drove the electrodes and wires used in EDM. These motors suffered reduced machining accuracy from backlash, the conversion between rotational and linear motion. Linear motors, which make use of the same magnetic engine technology that drives Japanese bullet trains, are far more efficient and capable of greater speeds and acceleration. Due to their great speed, linear motors generate a large amount of heat at the magnets, forcing the operator to circulate chilled coolant or suffer from reduced magnet life.

Read: EDMs Spark Interest

The rapid Z-axis movement linear motors produce during sinker EDM creates a natural flushing system as the electrode enters and exits the work area. This enables operators to machine shapes up to 4 inches deep without auxiliary flushing while maintaining a uniform spark gap and improving surface finish.

Wire EDM also sees benefits from linear motors, with surface finish, machining time and accuracy gains. The accuracy and responsiveness of linear motors improve corner accuracy, positioning accuracy and roundness capabilities over ballscrew-driven setups. Increased surface finish in a single skim pass can eliminate additional passes — reducing machining time by as much as 60% on certain wire EDM jobs. The X- and Y-axes of wire EDM do not move at the same speed as the Z-axis in sinker EDM, meaning linear motors generate less heat in wire EDM and often do not require cooling lines.

For recent topics in EDM, visit the MMS EDM information zone.

RELATED CONTENT

-

How To Passivate Stainless Steel Parts

You’ve made sure the parts were machined to spec. Now, make sure you’ve taken steps to protect those parts in the condition your customer expects them.

-

When To Use A Collet Chuck

Don’t assume the standard chuck is the right workholding for every lathe application.

-

Surface Finish: A Machinist’s Tool. A Design Necessity.

Simple “roughness” measurements remain useful in the increasingly stringent world of surface finish specifications. Here’s a look at why surface measurement is important and how to use sophisticated portable gages to perform inspections on the shop floor.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)