Leading The Charge: Battery-Electric Locomotives Will Be Pushing US Freight Trains Further | GE News

Adding even one battery-powered locomotive to the train could reduce the consist’s total fuel consumption by up to 15 percent, according to Alan Hamilton, general manager of systems engineering at GE Transportation. Given that diesel prices globally have hovered between $2 to $4 per gallon for most of the last decade, an operator could save tens of thousands of dollars per consist on its annual fuel bill. “It’s a big deal,” Hamilton says. “Fuel costs are typically the largest component in a rail operator’s costs.”

First some background. Diesel-electric locomotives like the machines GE is building are essentially power plants on wheels. They use a powerful diesel engine to generate the electricity that drives the electric motors that spin the wheels.

The battery-powered locomotive is the perfect complement to its diesel-electric brethren. The battery will hold 2,400 kilowatt-hours of energy, meaning it’s able to maintain full horsepower for roughly 30 minutes on a given charge. Then the operator can decide how to use that power.

For example, the operator could slash emissions from the diesel-powered locomotives by drawing heavily on the battery to start up the train. This would be especially desirable if the train were pulling out of a city rail yard, close to populated areas. Using the battery power also cuts down on noise. The train operator may also choose to “graze” on battery power — or even recharge the battery — when the train is cruising through open landscape, saving hundreds of gallons of diesel.

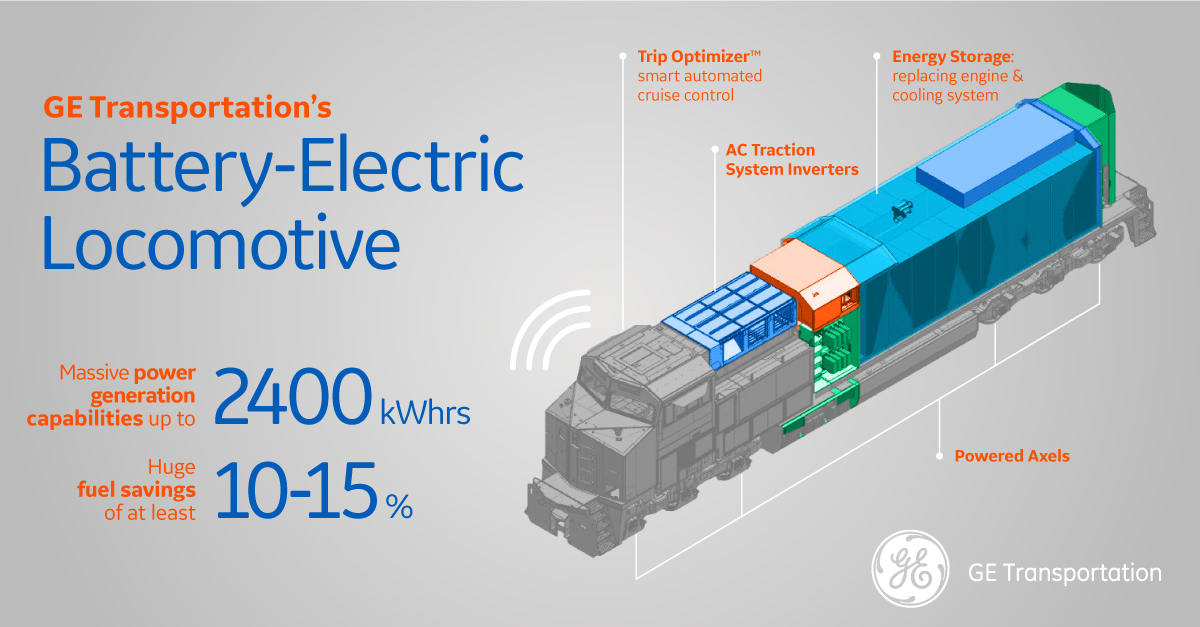

GE Transportation is developing a battery-electric locomotive that could give railway operators a big boost in fuel efficiency. Image credit: GE Transportation. Top image credit: GE Trasnportation.

GE Transportation is developing a battery-electric locomotive that could give railway operators a big boost in fuel efficiency. Image credit: GE Transportation. Top image credit: GE Trasnportation.

Each battery locomotive also has a brain, in the form of an onboard supervisory control system. The rail operator can input data about the train’s journey into the system — such as how much weight it’s hauling, the types of locomotives in the consist, and its rout — to allow the computer to make decisions about the best way to use the battery before the train even pulls away. “The trip-optimizing software can look ahead and predict the most efficient way to generate and use that energy,” Hamilton says.

For example, imagine a battery-enhanced train making a 500-mile trip across sparsely populated terrain — meaning fuel economy is the name of the game. The software will calculate the optimum ratio of battery power to diesel usage for such a journey and decide on the most favorable balance for the hybrid locomotive consist. The software can then pinpoint the exact moments to draw on the battery, thus sparing diesel. GE’s flexible solution will give rail operators several new options for optimizing their network, says Dennis Peters, executive product manager at GE Transportation.

The new locomotive will use a battery cell similar to what you might find under the hood of an electric car. It is a lithium-ion energy storage unit with cells that contain a combination of nickel, manganese and cobalt. In terms of scale and packaging, however, “this train battery is a different animal,” Peters says.

A standard electric-car battery usually holds a few hundred storage cells — each around the size of a mini tablet computer. But the prototype of the new locomotive will have a battery with approximately 20,000 cells, and future versions may have as many as 50,000 cells. The cells also must be able to weather the heavy-going environment of a locomotive, with all its jolts and shocks.

To build the demonstration model, workers will strip out the engine and cooling systems from a diesel locomotive to make way for the battery under the hood. But from the outside, the battery-powered locomotive won’t look much different from its diesel counterparts.

It’s perhaps no surprise that GE is leading the charge in battery-powered locomotives, given the company’s rich history in diesel-electric technology. Take one of the company’s most famous employees, Hermann Lemp, a Swiss-born engineer who immigrated to the United States in 1882 with a dream of working with his idol, Thomas Edison.

Lemp witnessed Rudolf Diesel’s pre-World War I experiments with his eponymous engine, then took it a step further: He perfected a crucial lever that coordinated output between the diesel engine and an electric generator. His invention of diesel-electric traction control helped put the steam train, that romantic image of the Industrial Age, out of business many decades — and many improvements — later.

Now the time has come to add batteries — and a brain.

Trains have been a crucial part of America’s infrastructure ever since two locomotives drew nose-to-nose at Promontory Summit in Utah on May 10, 1869, marking the completion of the First Transcontinental Railroad. Last year alone, trains pulled by diesel locomotives moved $174 billion worth of grain, coal and other freight across the U.S., second only to trucks and as much as four times more fuel-efficient than trucks.Trains could soon gain an even greater edge. Within two years, BNSF Railway Company, the company that oversees one of the largest freight railroad network in North America, will demonstrate a battery-powered locomotive paired with diesel locomotives in a “consist” — which is jargon for a sequence of connected locomotives — to power a freight train along a stretch of rail in California’s Central Valley between Stockton and Barstow. BNSF will run the pilot program with help from GE Transportation, which is developing the locomotive.Adding even one battery-powered locomotive to the train could reduce the consist’s total fuel consumption by up to 15 percent, according to Alan Hamilton, general manager of systems engineering at GE Transportation. Given that diesel prices globally have hovered between $2 to $4 per gallon for most of the last decade, an operator could save tens of thousands of dollars per consist on its annual fuel bill. “It’s a big deal,” Hamilton says. “Fuel costs are typically the largest component in a rail operator’s costs.”First some background. Diesel-electric locomotives like the machines GE is building are essentially power plants on wheels. They use a powerful diesel engine to generate the electricity that drives the electric motors that spin the wheels.The battery-powered locomotive is the perfect complement to its diesel-electric brethren. The battery will hold 2,400 kilowatt-hours of energy, meaning it’s able to maintain full horsepower for roughly 30 minutes on a given charge. Then the operator can decide how to use that power.For example, the operator could slash emissions from the diesel-powered locomotives by drawing heavily on the battery to start up the train. This would be especially desirable if the train were pulling out of a city rail yard, close to populated areas. Using the battery power also cuts down on noise. The train operator may also choose to “graze” on battery power — or even recharge the battery — when the train is cruising through open landscape, saving hundreds of gallons of diesel.Each battery locomotive also has a brain, in the form of an onboard supervisory control system. The rail operator can input data about the train’s journey into the system — such as how much weight it’s hauling, the types of locomotives in the consist, and its rout — to allow the computer to make decisions about the best way to use the battery before the train even pulls away. “The trip-optimizing software can look ahead and predict the most efficient way to generate and use that energy,” Hamilton says.For example, imagine a battery-enhanced train making a 500-mile trip across sparsely populated terrain — meaning fuel economy is the name of the game. The software will calculate the optimum ratio of battery power to diesel usage for such a journey and decide on the most favorable balance for the hybrid locomotive consist. The software can then pinpoint the exact moments to draw on the battery, thus sparing diesel. GE’s flexible solution will give rail operators several new options for optimizing their network, says Dennis Peters, executive product manager at GE Transportation.The new locomotive will use a battery cell similar to what you might find under the hood of an electric car. It is a lithium-ion energy storage unit with cells that contain a combination of nickel, manganese and cobalt. In terms of scale and packaging, however, “this train battery is a different animal,” Peters says.A standard electric-car battery usually holds a few hundred storage cells — each around the size of a mini tablet computer. But the prototype of the new locomotive will have a battery with approximately 20,000 cells, and future versions may have as many as 50,000 cells. The cells also must be able to weather the heavy-going environment of a locomotive, with all its jolts and shocks.To build the demonstration model, workers will strip out the engine and cooling systems from a diesel locomotive to make way for the battery under the hood. But from the outside, the battery-powered locomotive won’t look much different from its diesel counterparts.It’s perhaps no surprise that GE is leading the charge in battery-powered locomotives, given the company’s rich history in diesel-electric technology. Take one of the company’s most famous employees, Hermann Lemp, a Swiss-born engineer who immigrated to the United States in 1882 with a dream of working with his idol, Thomas Edison.Lemp witnessed Rudolf Diesel’s pre-World War I experiments with his eponymous engine, then took it a step further: He perfected a crucial lever that coordinated output between the diesel engine and an electric generator. His invention of diesel-electric traction control helped put the steam train, that romantic image of the Industrial Age, out of business many decades — and many improvements — later.Now the time has come to add batteries — and a brain.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)