Electric Hoist: What Is It? How Does It Work? Types, Uses

Mục Lục

Electric Hoist

Contact Companies

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Get Your Company Listed on this Power Page

Introduction

This article takes an in depth look at electric hoists.

Read further and learn more about topics such as:

- Overview of electric hoists

- Operating principles of electric hoists

- Considerations in electric hoist selection and operation

- Applications of electric hoists

- And much more…

Chapter 1: Overview of Electric Hoists

Electric hoists are material handling equipment used for lifting, lowering, and transporting materials and products. They are powered by an electric motor and have a controller to adjust the lifting parameters. They are efficient in carrying heavy loads and can perform lifting tasks in which the use of conveyors and cranes is impractical and not feasible. The other types of hoists based on the driving mechanism are the pneumatic hoists (or air hoists), hydraulic hoists, and manual hoists.

Electric hoists are positioned overhead above the object to be lifted. They require access to electrical power sources, hence, they are typically found indoors. They are commonly found in warehouses, automotive servicing and machine shops, and manufacturing facilities. Most electric hoists are designed to withstand hazardous and high-temperature environments. There are also electric hoists designed for cleanroom environments that are suitable for handling food and pharmaceutical products. Safety protocols in operating electric hoists must be practiced in all environments.

The use of electric hoists increases operational efficiency by eliminating manual lifting and positioning tasks that require intense effort. They uphold physical ergonomics in the workplace. Electric hoists have faster operation than other types of hoists. They are cost-efficient and consume less space than conveying systems.

Chapter 2: Operating Principle of Hoists

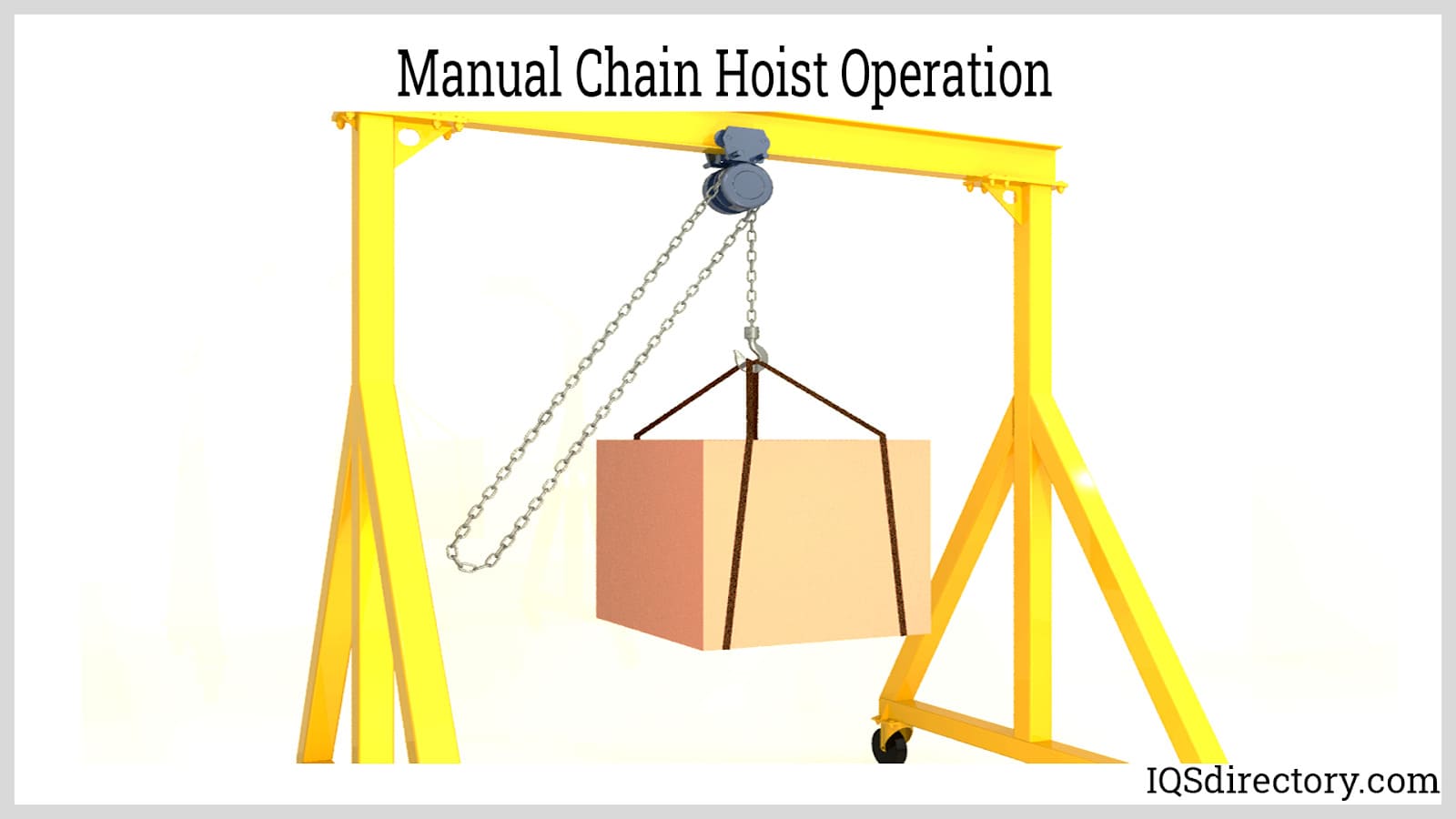

Manual Chain Hoist

Manual chain hoists concentrate a low force with high travel input into a high force but low travel output. This is the cause of their slow operation. They utilize multiple gears with different number teeth inside their lifting mechanism, which is activated by pulling the hand chain several times. This principle is responsible for accomplishing the task of lifting a heavy object.

A manual chain hoist is suspended above the object to be lifted by hooking or mounting it on a rigid and sturdy structural frame. It has two chains: the hand chain that is pulled by hand and the load chain, made of high-strength material, (e.g., steel) that lifts the load. The hand chain is much longer than the load chain. First, a grab hook is attached to the object to be lifted. The worker, who is situated at a safe distance from the load, pulls the hand chain several times. As the worker pulls the hand chain, it turns the cog; this causes the driveshaft to rotate. The driveshaft transmits the force into a series of gears with a different number of teeth. The force is concentrated by transmitting the torque from the fast-moving, smaller gears to slow-moving, larger gears. This force rotates the sprocket, which pulls the load chain together with the object. The load chain is looped around the sprocket as it decreases its exposed length and vertically displaces the object.

The ratchet of a manual chain hoist is located on the rear of the cog. It serves as a braking system for the manual chain hoist. The clutch clicks on the teeth of the ratchet and prevents the cog from slipping on the side of the load. As the cog rotates in the reverse direction, the clutch disengages from the ratchet and allows the hoist to lower the load.

Manual chain hoists have been replaced to necessitate less human intervention in lifting tasks. Electric hoists have made this possible. Electric hoists operate by utilizing a chain or a wire rope as the lifting medium.

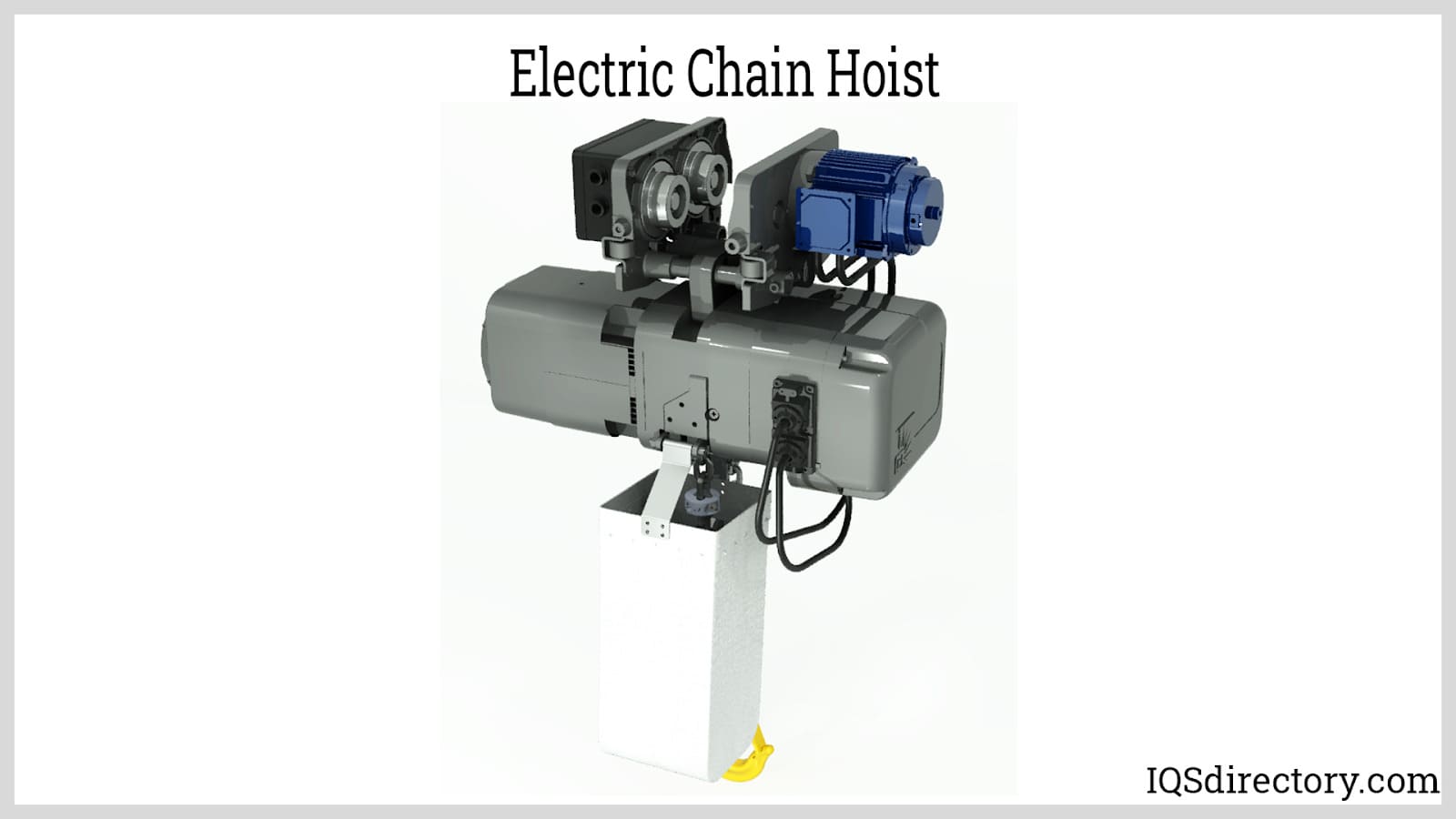

Electric Chain Hoist

Electric chain hoists use a load chain as the lifting medium. The load chain is pulled by a motor that converts electrical energy to mechanical energy used to lift the load. The electric hoist motor is housed inside a heat-dissipating shell, which is typically made from aluminum. The hoist motor is equipped with a cooling fan to dissipate heat quickly during its continuous service and to enable its operation in hot environments.

An electric chain hoist is suspended above the object to be lifted by hooking or mounting it on a rigid structural frame. A hook is attached to the end of the load chain that grabs the object. To commence the lifting operation, the worker switches on the hoist motor. The motor is incorporated with a brake; the brake is responsible for stopping the motor or holding its driven load by applying the necessary torque. The power supply is continuously released by the break during the vertical displacement of the load.

The motor generates torque and transmits it to a series of gears inside the gearbox. The force is concentrated as it passes through the series of gears that rotate the chain wheel to pull the load. As the object increases its distance above the ground, the length of the load chain is collected inside a chain bag, which is typically made from a high wear-resistant textile (e.g., nylon, ABS) or a plastic bucket. The chain bag must ensure the chains are not entangled and are free to slide. The load chain requires lubrication to run smoothly and safely.

Electric chain hoists are equipped with a limit switch that signals the motor to stop automatically in cases where the load exceeds the load rating. They can move the load from one position to another when it is attached to a trolley. The load positioning, as well as the emergency stop, can be manipulated by the worker through the controller.

Electric chain hoists are low maintenance and have easier installation than electric wire rope hoists. They can be used in a variety of environments. The use of electric chain hoists is a cost-effective option.

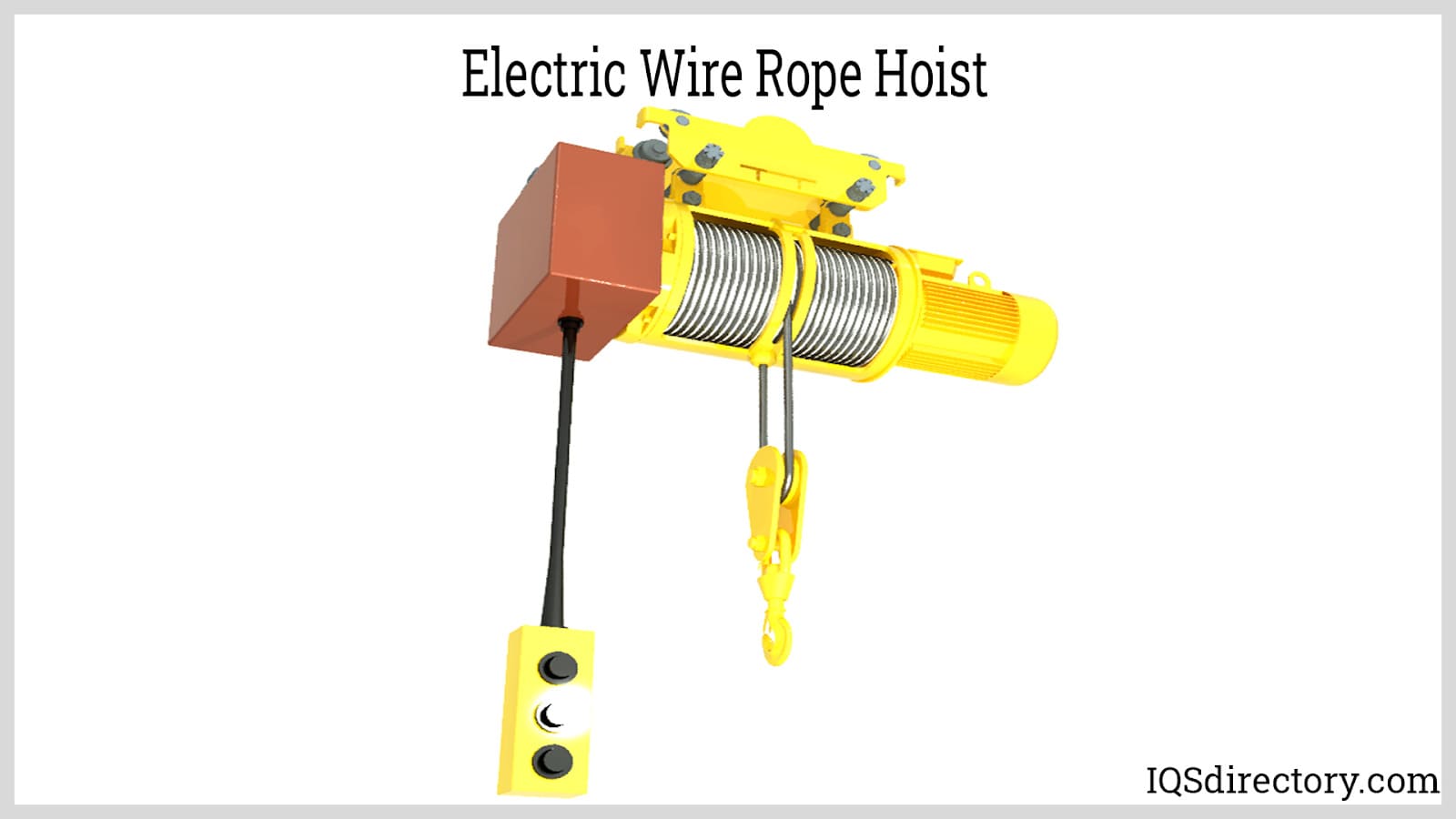

Electric Wire Rope Hoist

Electric wire rope hoists lift loads utilizing a wire rope as the lifting medium. Wire ropes consist of a core that runs through the center of the wire rope and several strands of wire intertwined around the core. This construction forms a higher-strength composite rope. Wire ropes intended for hoisting applications are typically made from carbon steel, stainless steel, Monel, and bronze; these materials have high resistance to wear, fatigue, abrasion, and corrosion.

Electric wire rope hoists, like electric chain hoists, are equipped with a hoist motor with an incorporated braking system. They also utilize a series of gears inside a gearbox that amplify the transmitted torque from the motor. The concentrated force from the gearbox is transmitted to a spline shaft. The spline shaft then rotates the winding drum. As the wire rope is pulled to vertically displace the load, it is wound around the winding drum. The rope guide moves around the winding drum to place the wire rope properly in the grooves, which run helically on the winding drum lateral. The rope guide prevents the wire rope from tangling. The wire rope also requires lubrication.

Electric wire rope hoists are also equipped with almost the same positioning controllers and safety features electric chain hoists possess.

Electric wire rope hoists can lift heavier loads at long lift heights. They are commonly used in heavy-duty and fast lifting applications. They are more capable of lifting and supporting loads for a prolonged period. However, the wire ropes may not be as durable as load chains in some instances. They are also more expensive than electric chain hoists.

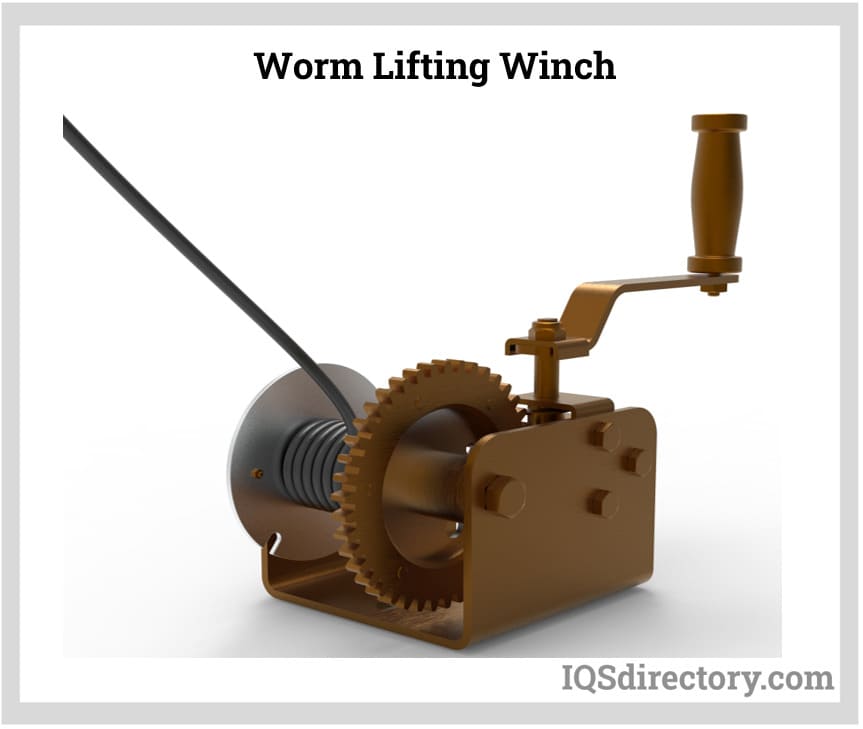

Winches

Winches and hoists are designed to lift or move heavy loads safely and easily. Though they have similar functions, they are engineered differently to perform different tasks. Unlike hoists that lift loads vertically, winches are designed to move loads horizontally over inclines and flat surfaces.

The construction of a winch is quite similar to that of a hoist. They are mechanical mechanisms that wind cable to create enough tension to pull or drag heavy objects. As with hoists, winches can be manually or electrically operated and have a steel drum with a cable wound around it.

Winches have a gear braking mechanism that holds a load in place when the pull of the cable stops. This is especially helpful on inclines. A hoist is hooked to a load vertically and pulls a load straight up with the wire rope or chain secured to the load with a sling, load mechanism, or other form of device.

The hook on a winch attaches directly to the load to be moved. When it is being connected, its locking mechanism is disengaged while its cable is pulled out by the operator and hooked to the load. In many cases, the hook may be placed through a section of the load and hooked to the cable where the cable serves as a type of sling. This configuration is forbidden with hoists.

When the drum for a winch is activated, its motor gradually pulls until the proper tension is reached. It is extremely critical that the load capacity of the winch and its cable be followed since a snap or breaking of the cable can cause very serious harm to anyone standing in the area.

There is normally some confusion for people who are not familiar with the difference between winches and hoists. In many cases, the terms are used interchangeably. The distinction between the two can be summarized in their function. A hoist lifts vertically while a winch pulls horizontally. These basic functions are further differentiated by the components of each mechanism.

Using a pulley or set of pulleys, winches can be used as a lifting mechanism for light loads. For floor mounted winches, the cable is thread up to a pulley and down to a load, a configuration that makes it possible for a winch to make a vertical lift. Other types of winches can be mounted on beams or walls and attached to a pulley mechanism and can be electrically or manually operated.

High capacity winches can be found in shipyards with kilonewton capacities of 10 or 15 kN up to over 200 kN. Shipyard winches come in several configurations with one or more drums.

Leading Manufacturers and Suppliers

GET YOUR COMPANY LISTED ABOVE

Chapter 3: Considerations in Electric Hoist Selection and Operations

Suspension

Electric hoists can be differentiated according to the type of suspension used to position the hoist above the load:

Hooks

Hook-mounted hoists have a top hook that enables them to attach temporarily to a trolley or beam clamp. This is the simplest suspension method. A top hook usually has a safety latch to keep the load from swaying or accidentally slipping.

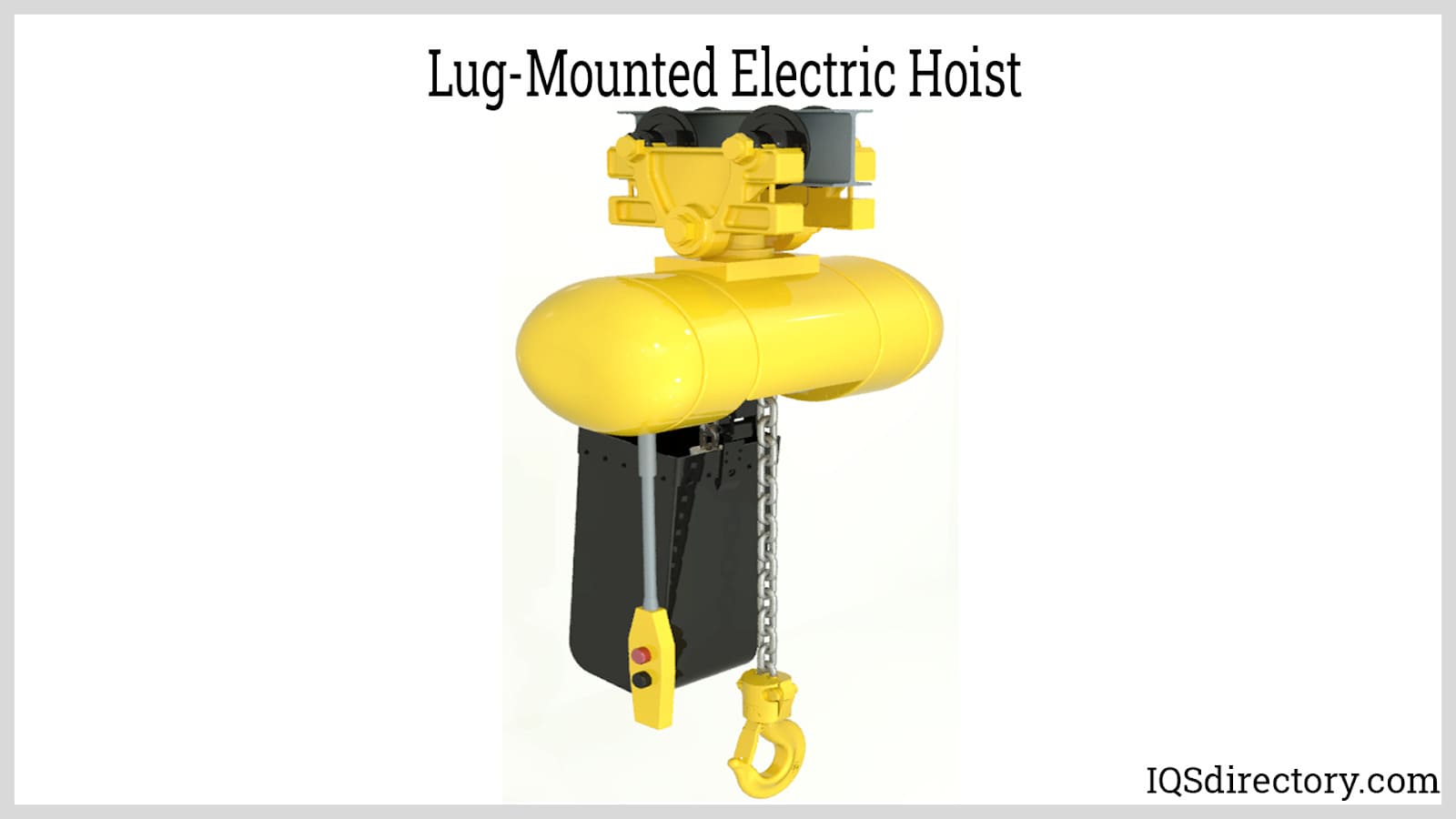

Lug Mounts

Lug-mounted hoists are suspended by bolting their top to a wall or an overhead beam. They are fixed securely to the spot where the load must be lifted. They may be allowed to traverse to another position.

Trolleys for Load Transportation

Trolleys are attached to the electric hoist and are responsible for transporting the electric hoist across the length of the beam. They facilitate the movement and positioning of the hoist from one point to another.

Push-Type Trolley

Electric hoists with push-type trolleys (plain trolleys) have a suspension mechanism that enables the hoist to traverse horizontally by manually dragging the hoist for a specific distance. The hoist may be pushed or pulled along the length of the beam whether the hoist is loaded or not. Among the trolley-type suspensions, push-type trolleys have the lowest positioning accuracy and require the greatest effort.

Geared Trolley

Geared trolleys are operated by a hand chain, which is manually pulled several times to make the hoist travel.

Electric Travel Trolley

Electric travel trolleys have an electric motor that moves the hoist a specific distance. The controls for the travel direction and speed are integrated into the electric hoist controller system. Electric travel trolleys offer higher travel accuracy and precision for the least effort.

Beams

The bridge, in which the trolley is mounted and traverses, is made up of beams. The bridge and its structural frame must be rigid and durable enough to support the combined load of the electric hoist and the object to be lifted. The chosen specifications and dimensions of the beam and the electric hoist trolley must be compatible with each other for the electric hoist to travel smoothly. The common types of beams used for hoisting applications are the I-Beams, wide-flange beams, and patented track beams.

The rated capacity, working load limit, and duty cycles are some of the specifications that will help engineers and workers to select an electric hoist that fits the lifting requirement.

Rated Capacity

Rated capacity is the maximum weight a hoist can carry before buckling. It depends on the capacity of the motor, rigidity of the electric hoist assembly, and strength of the load chain or wire rope.

Working Load Limit

The working load limit is the maximum allowable weight a hoist can safely carry. It is determined by multiplying the minimum breaking load to a factor of safety. The factor of safety depends on the construction of the hoist, possible threat to the workers, and environment.

Duty Cycle

As the worker uses the hoist more frequently, wear down becomes more likely. Duty cycle is the duration of time the hoist can operate under normal conditions and parameters. For instance, an electric hoist should only be operated for one minute and is shut off for 99 minutes; therefore, the duty cycle is 1/100 or 1%. Using a hoist beyond the duty cycle can accelerate its wear and shorten the service life.

Lifting speed and travel speed affect production and turnaround times. They are a couple of the specifications to pay attention to with an electric hoist:

Lifting Speed

Lifting speed refers to how quickly the load is lifted or lowered from its original position. An electric hoist can have a fixed or an adjustable lifting speed, which is set using the hoist controller. Slower speeds are used if the load is fragile, heavy, and/or needs slow and precise positioning. Faster speeds are used for fast production and transportation. Moderate speeds are used for loading and unloading of products.

Travel Speed

Travel speed refers to how fast the trolley traverses a specific distance to move the load. An electric hoist can have a single operating travel speed or an adjustable travel speed, which is manipulated using the hoist controller.

Safety Precautions in Operating Electric Hoists

Before work begins:

- Every type of hoist requires a certain level of training. Before an operator is approved to operate any type of hoist, they should be properly trained and approved by their supervisor.

- Part of hoist training is knowing the components of the hoist and its weight load capacity. Much of this information is part of the owner’s manual and what a manufacturer provided as guidelines. Since hoists have several key components that function together during operation, it is important that operators understand and have experience with each of the components.

- OSHA requires that warning labels be placed on any piece of equipment that can be considered a safety hazard. Reading warning labels and knowing the potential malfunctions and hazards of a hoist that may occur during operation is an essential and necessary part of hoist operation.

- Prior to operation, emergency shut offs, kill switches, and other types of safety measures should be identified and located prior to hoist operation. Should malfunctions occur, it’s important to know what to do to immediately cease operation to prevent accidents and who to notify.

Pre-work inspection:

- Attached to every hoist is a checklist that must be completed prior to operation. Included in the checklist are features, aspects, and areas of the hoist that require inspection. Most checklists are dated in regard to the last time the hoist was activated and if there were any problems during operation.

- Check the hook and cable or chain for nicks, gouges, cracks, twist, saddle wear, load-bearing point wear, and throat opening deformity. The chain or wire rope should be sufficiently lubricated prior to operation.

- Wire rope should be inspected and examined for crushing, kinking, distortion, birdcaging, unstranding or strand displacement, broken or cut strands, and general corrosion.

- Short and brief tests of the controls should be completed for proper functionality as well as examinations of wiring and connectors.

While operating the hoist:

- Loads should be secured using a hook and sling or lifter. Care should be taken to ensure that the hoist is not overloaded.

- The hook and upper suspension should be in a straight line. The chain or body of the hoist should not come in contact with the load.

- The area around and under the load should be clear of all personnel. For extremely heavy or awkward loads, warnings may be necessary to inform people in close proximity to the load.

- All hoists have a published load capacity that must be strictly followed to ensure the safe performance of the hoist. Serious and dangerous outcomes can be the result of not adhering to hoist guidelines and weight limits.

While parking the load:

- As with the lifting of a load, the area where the load will be placed must be cleared of all personnel. The load should be slowly and carefully placed on a stable and firm foundation.

- The surface where the load will be placed should have some types of supports such as blocks upon which the load can be positioned. Setting a load directly on a flat surface makes it difficult to remove slings and other support devices.

- As the load is parked, tension on its chain or wire rope should be slowly released should that the chair or wire rope do not snap when the load is released. .

- Once the load is parked and placed, the hook, chain or wire rope, and sling should be raised to seven or eight feet above the surface and out of the way of foot traffic.

Chapter 4: Applications of Electric Hoists

Electric hoists may be used as stand-alone equipment or mounted structural frames and tracks as a part of a lifting system. These types of lifting systems are:

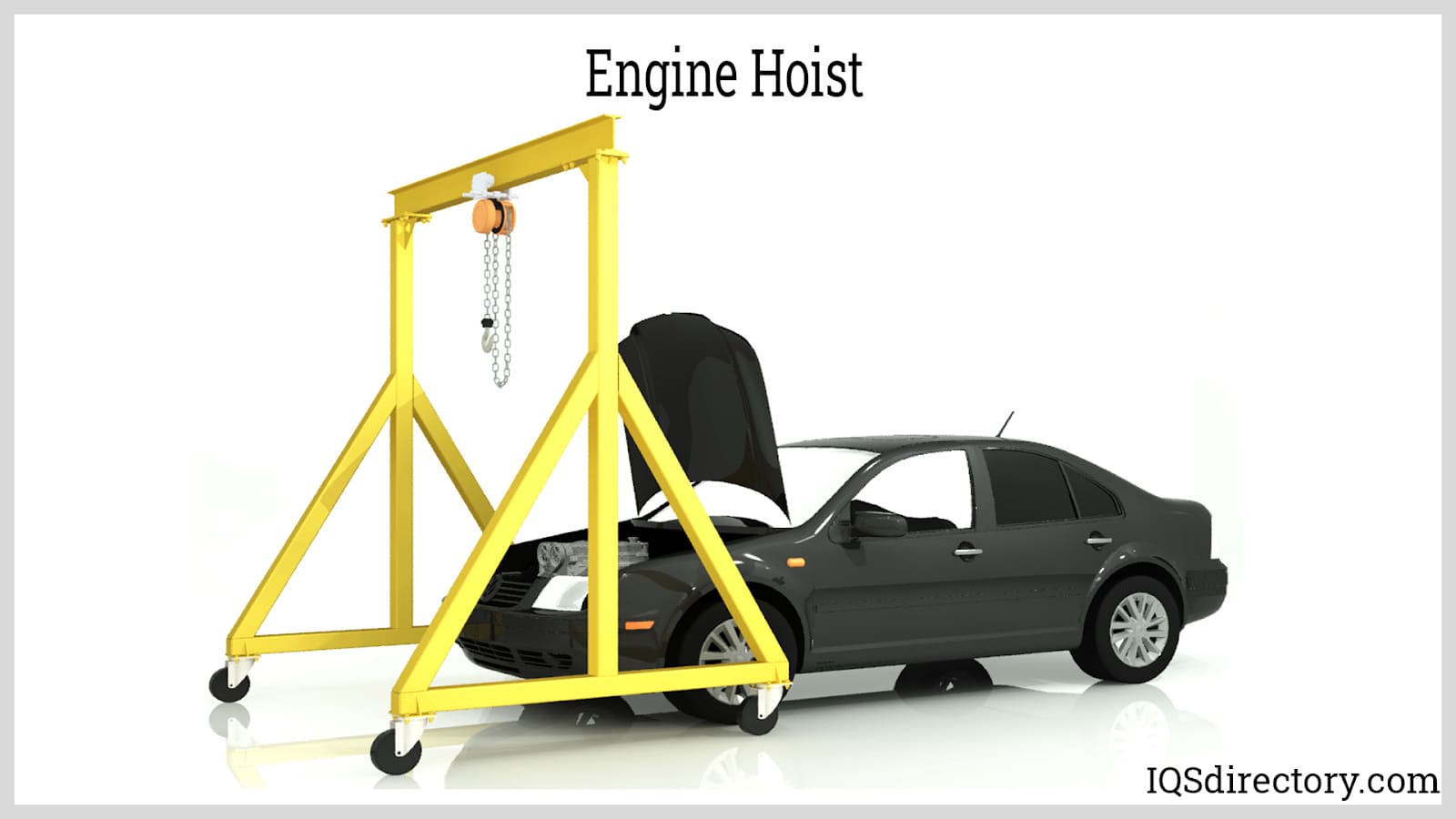

Engine Hoists

Engine hoists, or engine cranes, are used to assist the workers in the installation and maintenance of engines of automobiles. They are designed to lift the engine under the automobile hood. Their electric hoists are mounted on top of the rigid and portable structural frame. The structural frame has wheels installed at its base to easily maneuver the hoist over the automobile, as well as to transport it around the machine shop. Its portability makes it suitable for outdoor applications. The structural frame of some engine hoists is foldable, so it can save space when it is stored.

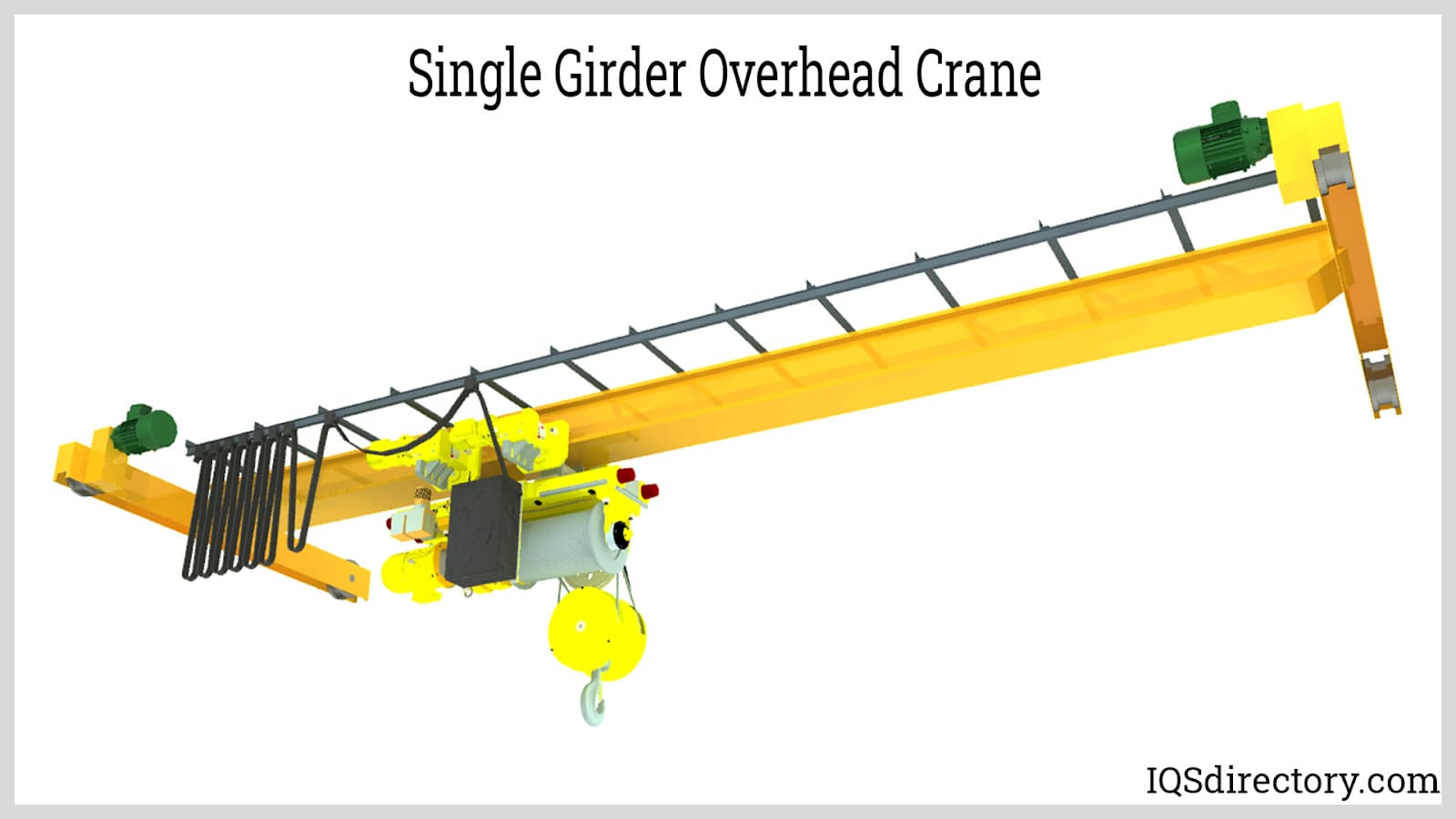

Overhead Cranes

The installation of overhead cranes is planned during the early stages of a building‘s construction, as they require a much greater amount of structural support. Overhead cranes lift the heaviest loads at the highest lifting heights in an enclosed facility.

In overhead cranes, there are two parallel end trucks mounted on runway beams . The runway beams are also responsible for supporting the entire overhead crane and the load. The end trucks travel along the rails of the runway beams together with the bridge and the electric hoist. The electric hoist travels across the length of the bridge. The bridge can either be a single girder or a double girder bridge. A single girder bridge crane has one trolley that moves across a single girder beam, while the double girder bridge crane has two trolleys that move the electric hoist synchronously across two girder beams. The bridge and the end trucks are positioned perpendicularly with each other. This arrangement enables the electric hoist to move left and right (via end trucks), and forward and backward (via the bridge). Lifting and positioning parameters are controlled remotely.

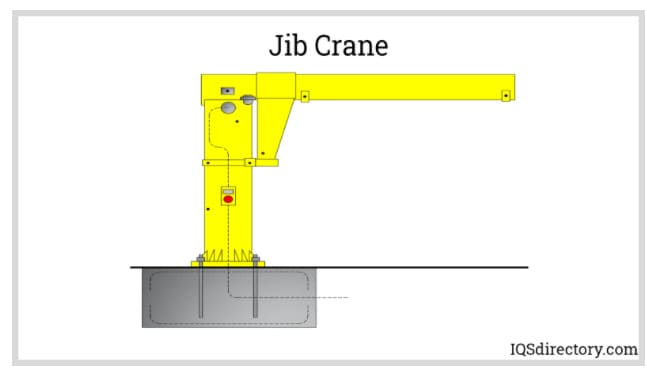

Jib Cranes

A jib crane has a lifting fixture that primarily consists of two large beams constructed to form a cantilever. The mast, or pillar, is the vertical beam of the fixture that supports the reach. The reach, or boom, is the horizontal beam of the fixture wherein the electric hoist travels to position the load. There are three types of jib cranes:

Floor-Mounted Jib Cranes

Floor-mounted jib cranes are self-supporting jib cranes that have their massive mast fixed on the floor. They are used to support the load of the main cranes. There are jib crane types and designs to improve the lifting service. Drop-mounted cantilever jib cranes feature an adjustable boom to adjust the lifting height. Most floor-mounted jib cranes can accommodate rotations of up to 360°.

In some applications, floor mounted jib cranes are referred to as base mounted hoists and have a similar function as that of a floor mounted jib crane. Base mounted hoists set on the floor and are used for vertical lifting of loads up a load line that moves through a heel and crown block at ground level or rooster head of a gin pole.

The main function of a base mounted hoist is to move goods up and down. They have a rope drum, gearbox, motor, brake, and panel. To enhance their strength and endurance, base mounted hoists are made of steel that is bolted or welded together with a load capacity of a half ton up to ten tons or more.

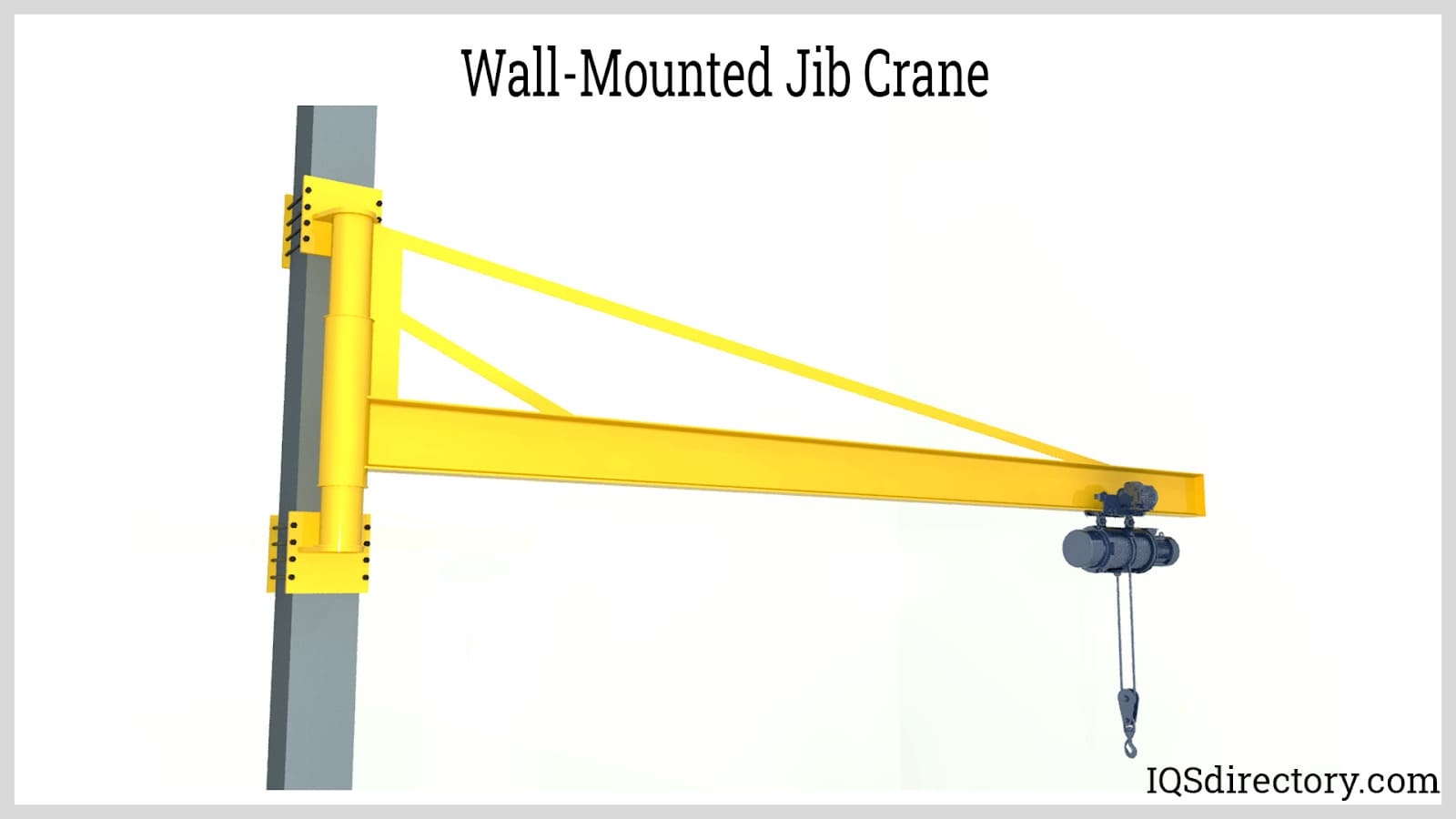

Wall-Mounted Jib Cranes

Wall-mounted jib cranes are mounted on a wall or columns that are structurally rigid to support them. The rotation of their reach is limited to 2000. There are two types of wall-mounted jib cranes. Cantilever wall-mounted jib cranes offer the greatest amount of clearance above and below the boom and exert less force on the building column. Tie-rod supported wall-mounted jib cranes are supported using a wall bracket and a tie rod. Since there is no support structure under the boom, the electric hoist is allowed to travel fully along the length of the reach.

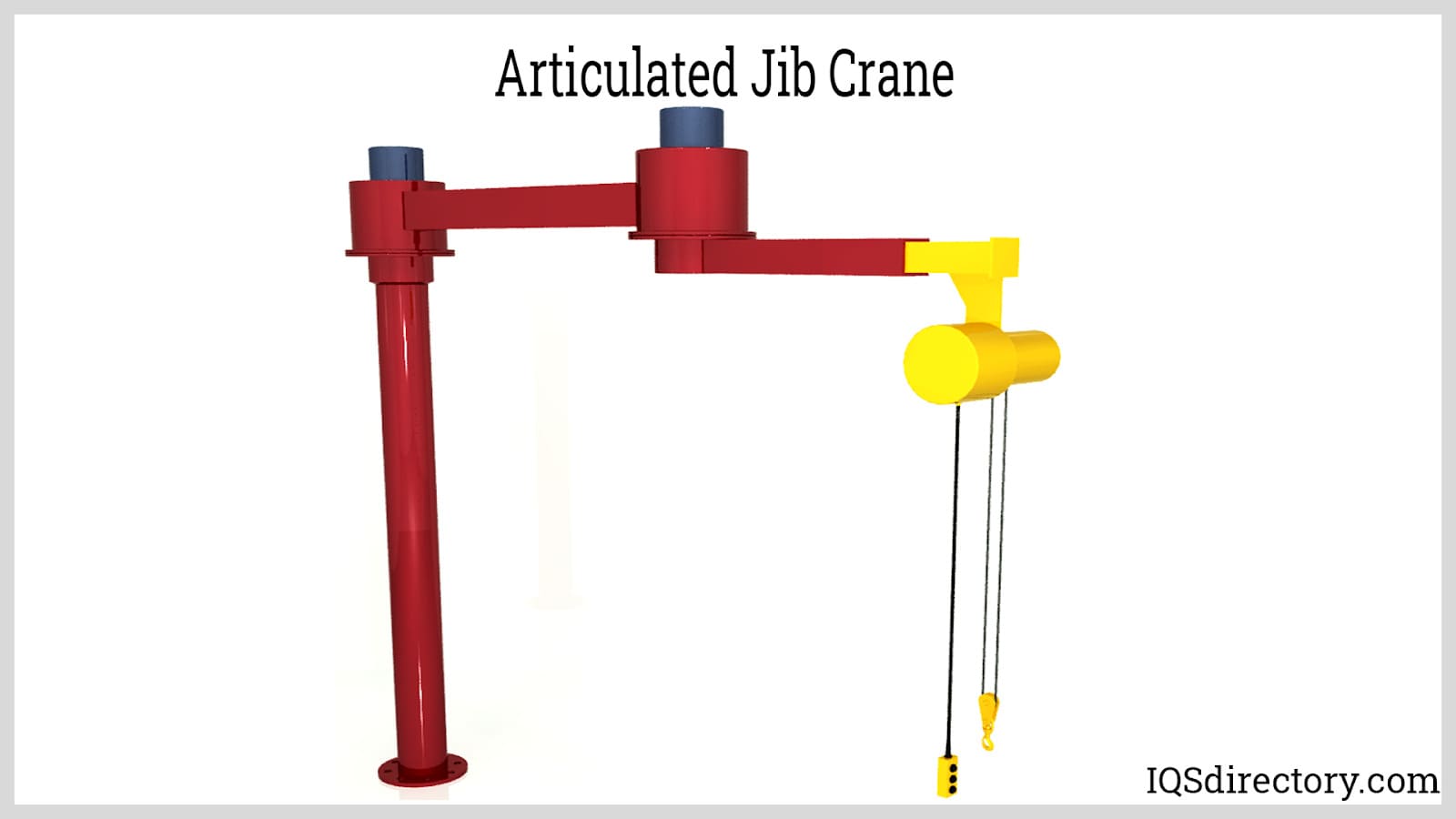

Articulated Jib Cranes

Articulated jib cranes consist of a mast and two boom arms that are flexed or folded at their joints. They can be mounted on the floor, ceiling, wall, or bridge crane. The primary boom arm, the arm that carries the load, is allowed to rotate 3600, while the rotation of the secondary boom arm is limited depending on where the articulating jib crane is mounted. Articulated jib cranes move the load flexibly in many possible directions.

Gantry Cranes

Gantry cranes are versatile lifting devices; their lifting fixtures consist of a horizontal overhead bridge supported by legs. The electric hoist travels along the length of the overhead bridge. Mobility is made possible by installing wheels on the base of the legs or making them run along a track. Unlike bridge cranes and jib cranes, gantry cranes do not require support from the building‘s structure. They can be used outdoors. They can be installed under bridge cranes to carry some of their load.

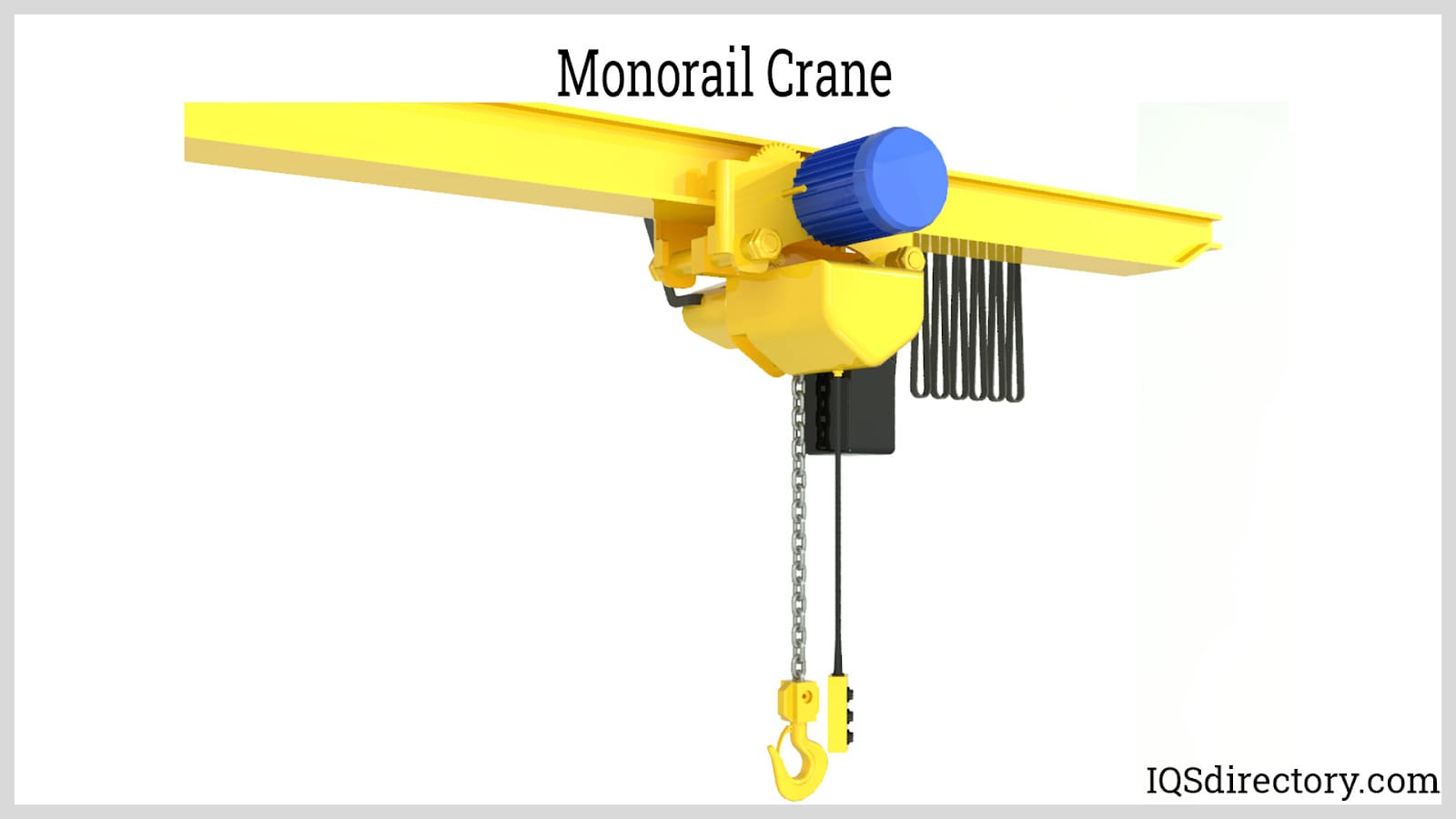

Monorail Cranes

Monorail cranes are a type of overhead crane used in production facilities and machine shops for repetitive lifting and positioning tasks. They are used to move loads to a restricted area. The electric hoist trolley runs on the outer flange of a single I-beam, which is already built on the ceiling structure of the building.

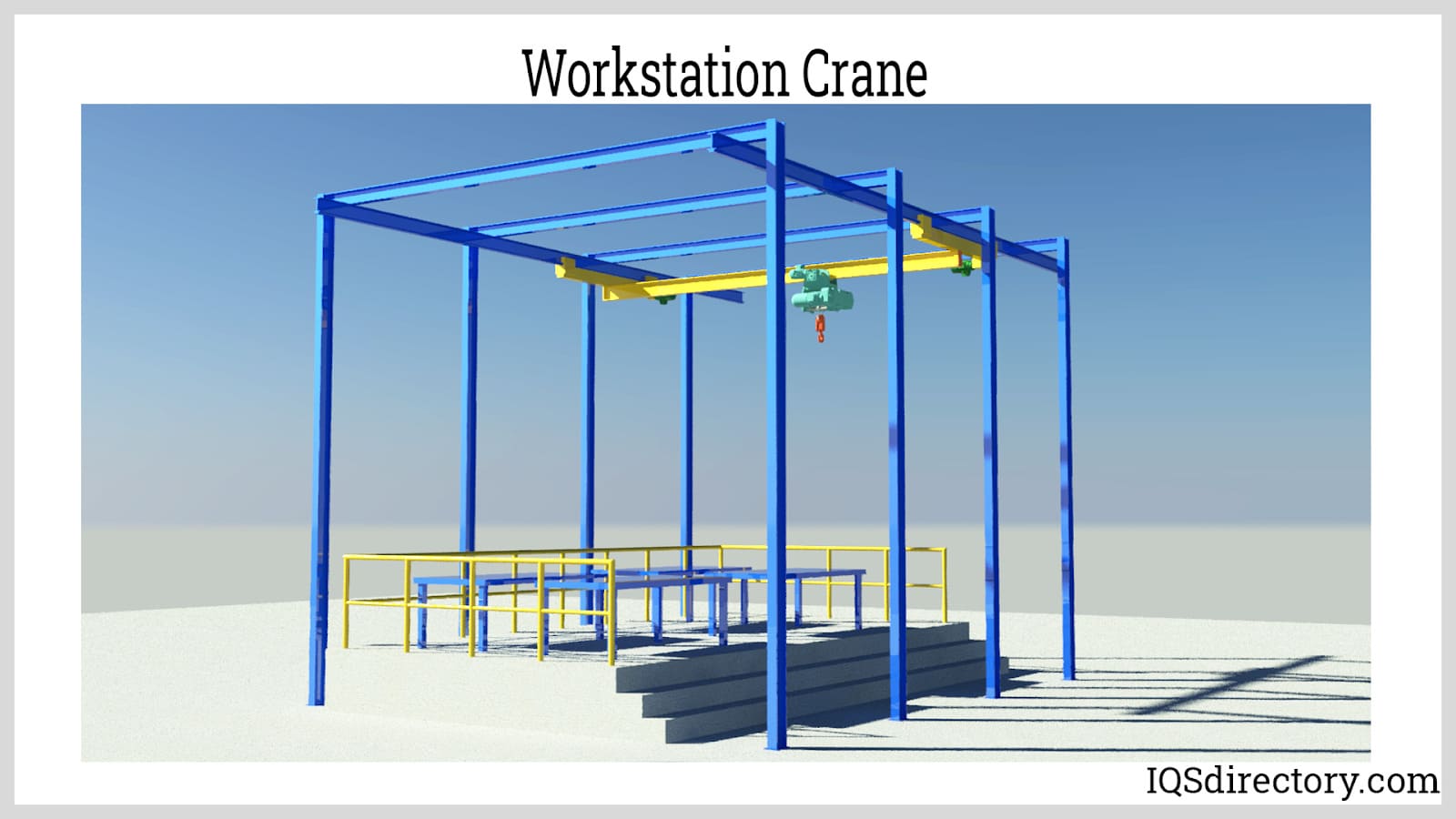

Workstation Cranes

Workstation cranes provide an ergonomic method of lifting and moving objects in a small work area. Their design is like that of overhead cranes except that the bridge is supported by free-standing columns. Workstation cranes have a smaller structural frame and provide shorter lifting heights. They are cost-effective alternatives to overhead cranes for light to medium duty applications.

Summary

- Electric hoists are material handling equipment that is used in lifting, lowering, and moving materials and products. They are positioned overhead and powered by an electric motor.

- The main types of electric hoists are the electric chain hoist and electric wire rope hoist.

- Electric hoists can be suspended by hooks or lugs.

- Trolleys are responsible for transporting the electric hoist. The types of electric hoist trolleys are the push type trolley, geared trolley, and electric travel trolley. They must be compatible with the beams of a lifting system‘s structural frame.

- Rated capacity, working load limit, and duty cycle are the critical specifications of electric hoists that pertain to their lifting capabilities. These lifting limitations must be observed to uphold safety.

- The travel speed and lifting speed of the electric hoists affect the production rate and turnaround time.

- Electric hoist components must be in top condition during operation. Hence, scheduled daily and periodic inspections and maintenance must be strictly performed. Safety precautions must always be observed during operation.

- Electric hoists may be used as stand-alone equipment or as part of a lifting system. Some of the applications of electric hoists are engine hoists, overhead cranes, jib cranes, gantry cranes, monorail cranes, and workstation cranes.

Leading Manufacturers and Suppliers

GET YOUR COMPANY LISTED ABOVE

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)