Business Process Improvement Opportunities – Revamp Your Business

There’s Always Room For Improvement – So Here’s How To Revamp Your Business Processes.

If your business is stagnant, doing the same thing day in and day out, it’s pretty unlikely that you’re going to see growth and success. Every business needs to evolve to remain competitive in the market. So the question isn’t ‘do we need to change things up?’, it’s actually ‘how should we evolve?’

Business process improvement (BPI) is an approach that identifies areas where the business could improve, redesigning the existing business processes to increase effectiveness and optimize performance. For the modern organization, undergoing a business process improvement is an ongoing necessity.

Every business has hundreds of processes, whether they have to do with community management, procurement, onboarding, or sales. They usually fall into one of these categories – operational, management, supporting. Operational activities are those that repeat every day, such as administrative, advertising, and sales activities. Management activities concentrate on human resources, financials, monitoring, and delegation. Supporting activities are the remaining undertakings such as recruitment, accounting, and IT support.

All tasks and activities require regular evaluation to determine if there are inefficiencies or room for improvement. When opportunities for improvement are identified, that’s where BPI comes in.

Luckily, you don’t have to go into BPI blind. Several BPI methodologies can help you achieve your goal, as they give you a framework that you can apply to your strategy.

Here are a few of the most popular ones:

Six Sigma

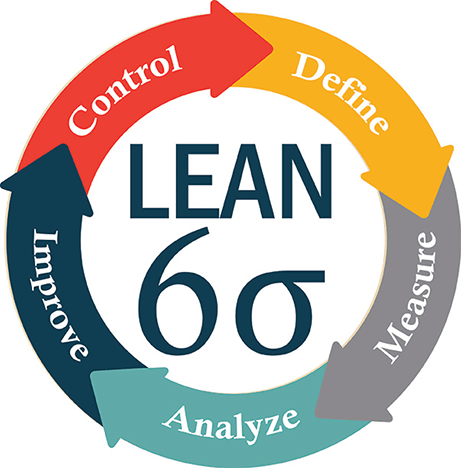

Six Sigma was first developed in the 1980s at Motorola to measure defects and improve overall quality. It was then popularized by General Electic, who wanted to reduce waste, improve the quality of the product, and save money. Today, companies all over the world use Six Sigma. Six Sigma contains two methodologies – DMAIC, which is used to improve an existing process, and DMADV, which is used when you want to create a new process.

For BPI, you would use DMAIC, which stands for:

Define – Define the problem

Measure – Quantify the problem

Analyze – Identify the cause of the problem

Improve – Solve the issue and verify improvement

Control – Maintain the returns

One interesting branch of the Six Sigma methodology is the Lean Thinking approach. The Lean Thinking approach considers everything in terms of the value to the customer – if they don’t bring value, they must be eliminated. It’s a great way of thinking when looking for process improvement opportunities. The customer is usually at the core of our business, so putting forefront the notion that value-added processes should be valuable to them, ultimately increasing the customer’s satisfaction.

Total Quality Management (TQM)

Under TQM, every organization section must draw customers, and their activities and processes should have customer values in mind. It aligns the entire organization to the same goal productively, and that’s what makes it unique.

One example of TQM’s success is AlantiCare, a healthcare provider located in New Jersey. Alanticare ensured that every individual in their organization gave essential feedback about the healthcare products they manufactured. Observing products from every perspective, including customer service, HR, marketing, etc., led to a total improvement of their products. Implementing TQM ended up boosting the company’s revenue, from $280m to $650m.

Implementing TQM in your organization can help everyone look for process improvement opportunities, as all employees will understand that customer values are at the center of the organization.

Theory of Constraints (TOC)

The Theory of Constraints framework uses a focusing process to identify constraints that affect the organization’s ability to achieve a goal and ultimately find a way to eliminate or work around it. This approach allows the company to increase productivity, streamline product flow, and optimize workflow.

Dr. Reddy’s Laboratories, a multinational pharmaceutical company, is a great example of how TOC can benefit an organization. Before implementing TOC, they faced high backorders and low supplier ratings. After implementing TOC, they tightened the supply chain to focus on better inventory management, finances, and project management. They started to track operating expenses, simplifying management accounting and reporting. Their success saw them win the best supplier of the year award.

When you think about the constraints hindering success and achievement in your organization, you will begin to see the opportunities for process improvement.

While these approaches provide us with a great framework to improve processes in our businesses, there are steps that we can follow to help commence the process improvement.

Mục Lục

Step 1: Identify what needs to change.

The first step is to look at your business processes, across the categories of operational, management, and support, at a high level. Think about what needs to change and why. Here is where you will find the process improvement opportunities. Get people from different departments and ranks involved to help you gain diverse perspectives and understand the company’s pain points. Think about how changing resource requirement levels of different processes would benefit the organization, what saved resources could be put towards.

You can also start with a goal and think about what opportunities there are for process improvement that would lead to achieving that objective. Let’s take Howard Bank as an example; they wanted to spend more time connecting with their new customers during the account opening process. They chose to improve the process efficiencies to achieve this. With a more streamlined process, the bank could engage in more meaningful conversations with customers, learn more about their financial needs, and give them a better experience.

Step 2: Think about how you’ll realistically improve this.

Now that you know what needs to be improved, you’ll need to come up with a plan to execute. Analyze the process in detail, examining where roadblocks are being created, what is taking up the most time unnecessarily, where costs are being wasted, and the impact on quality and delivery. You’ll want to make sure you talk to the people involved here; gaining their perspective on where improvements can be made will help you deeply understand the process.

Step 3: Get the right sign-offs and resource allocation.

In every business, a change to a process will require certain approvals and authorization. Once you have a solid idea of what needs to be improved and how you’ll do it, you can bring this to the necessary people. Here is where you should have an understanding of the resources required as well. Let senior management know what you need from them to execute.

Step 4: Make it happen.

Now that you’ve got an understanding of the process you’re going to improve, how you’ll do it, the approvals, and the resources allocated, it’s time to get going. Organize this as a project because it is one. Plan it out, allocate resources, assign a team and dedicate a deadline.

Conclusion

“A business that doesn’t change is a business that is going to die” – Frank Perdue.

Your business needs to change, adapt, and evolve. But without a proper approach to Business Process Improvement, you could be left worse off than you began. Want to stay ahead of the game? Follow these simple tips to help discover process improvement opportunities and implement the changes required.

![Toni Kroos là ai? [ sự thật về tiểu sử đầy đủ Toni Kroos ]](https://evbn.org/wp-content/uploads/New-Project-6635-1671934592.jpg)